Abstract

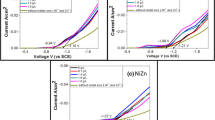

Among the main characteristics of silver and its alloys, tarnish resistance as well as surface brightness is essential. Alloying these materials with germanium has been shown to have considerable potential in providing tarnish protection. However, studies regarding the electrodeposited silver-germanium (Ag–Ge) alloy coatings are limited. The main objective of this study is to investigate the electrodeposition process of Ag-Ge alloy coatings with different Ge contents. In this regard, co-electrodeposition of Ag and Ge as an alloy coating was performed on pure copper substrates from a cyanide-based electrolyte. The effect of Ge incorporation on alloy composition, surface morphology, topography, texture, crystalline structure and cathodic efficiency of the obtained electrodeposits was investigated. Also corrosion properties of coatings were perused by polarization curves. Evaluation of the coatings was performed using different characterization techniques including XPS, SEM, FESEM, EDS, XRD, AFM, ICP, GIXRD, XRF, FTIR and electrochemical analysis. Results indicated that the optimum content of Ge in the coating was found to be 6 wt% regarding dense and uniform microstructure along with the best corrosion resistance. In addition, the X-ray diffraction patterns exhibited a shift in lattice parameter of Ag that was attributed to the Ag-Ge biphasic alloy formation. Moreover, the surface studies revealed a morphological transformation from nodular to cauliflower-like by increasing the Ge content of coating. The obtained polarization curves represent a remarkable decrease in Ag-6Ge alloy corrosion current density, about 20 times compared to Ag-0.5Ge and about 6 to pure silver. Discrepancies in characteristics between the Ag-Ge and pure Ag coatings were addressed and discussed.

Graphical abstract

Similar content being viewed by others

References

Jiang L, Wang W, Wu D, Zhan J, Wang Q, Wu Z, Jin R (2007) Preparation of silver quantum dots embedded water-soluble silica/PAAc hybrid nanoparticles and their bactericidal activity. Mater Chem Phys 104:230–234

Liao Y, Wang Y, Feng X, Wang W, Xu F, Zhang L (2010) Antibacterial surfaces through dopamine functionalization and silver nanoparticle immobilization. Mater Chem Phys 121:534–540

Khollari MAR, Azar MK, Esmaeili M, Tanhaei M, Dolati A (2020) others Elevated-temperature behaviour of LiNi0. 5Co0. 2Mn0. 3O2 cathode modified with rGO-SiO2 composite coating. J Alloys Compd 843:154924. https://doi.org/10.1016/j.jallcom.2020.154924

Hosseini M, Momeni MM (2010) Silver nanoparticles dispersed in polyaniline matrixes coated on titanium substrate as a novel electrode for electro-oxidation of hydrazine. J Mater Sci 45:3304–3310. https://doi.org/10.1007/s10853-010-4347-1

Ghani S, Sharif R, Shahzadi S, Zafar N, Anwar AW, Ashraf A, Zaidi AA, Kamboh AH, Bashir S (2015) Simple and inexpensive electrodeposited silver/polyaniline composite counter electrodes for dye-sensitized solar cells. J Mater Sci 50:1469–1477. https://doi.org/10.1007/s10853-014-8708-z

Momeni MM, Ghayeb Y, Gheibee S (2017) Electrodeposition of silver on CrTiO 2 nanotubes and study of their structural, morphological, optical and photocatalytic properties. J Mater Sci Mater Electron 28:2607–2614

Sultana I, Idrees M, Rafique MY, Ilyas S, Hussain SQ, Kahn AA, Razaq A (2018) Electrodeposition of silver (Ag) nanoparticles on MnO 2 nanorods for fabrication of highly conductive and flexible paper electrodes for energy storage application. J Mater Sci Mater Electron 29:20588–20594

Liu XM, Wu SL, Chu PK, Chung CY, Zheng J, Li SL (2006) Effects of coating process on the characteristics of Ag–SnO2 contact materials. Mater Chem Phys 98:477–480

Cusma A, Sebastiani M, De Felicis D, Basso A, Bemporad E (2015) Study on the correlation between microstructure corrosion and wear resistance of Ag-Cu-Ge Alloys. Coatings 5:78–94. https://doi.org/10.3390/coatings5010078

Johns PG (2019) Process for making finished or semi-finished articles of silver alloy. US Patent 10,323,310. https://patents.google.com/patent/US10323310B2/en

Youdelis WV, Youdelis William V (1978) Silver-copper-germanium alloys having high oxidation resistant melts. US Patent 4,124,380. https://patents.google.com/patent/US4124380A/en

Johns PG, Argentium International Ltd (2010) Silver ternary alloy. US Patent Application 12/766,312. https://patents.google.com/patent/US20100239454A1/en

Johns P, Harrison C, Middlesex Silver Co Ltd (2007) Enhancing silver tarnish-resistance. US Patent Application 10/551,476. https://patents.google.com/patent/US20070039665A1/en

Ke J, Bartlett PN, Cook D, Easun TL, George MW, Levason W, Reid G, Smith D, Su W, Zhang W (2012) Electrodeposition of germanium from supercritical fluids. Phys Chem Chem Phys 14:1517–1528. https://doi.org/10.1039/c1cp22555c

Subbaraman PR, Gupta J (1956) J Sci Ind Res 15:306

Pandey V, Ramachandrarao P (1987) A metastable phase in electrodeposited Ag-Ge alloys. Surf Coat Technol 30:401–404

Ghaffari S, Aliofkhazraei M, Darband GB, Zakeri A, Ahmadi E (2019) Review of superoleophobic surfaces: evaluation, fabrication methods, and industrial applications. Surf Interfaces 17:100340. https://doi.org/10.1016/j.surfin.2019.100340

Bahmani E, Zakeri A, Aghdam ASR (2020) A fast and efficient approach to fabricate tarnish-resistant nanocrystalline Ag-Ge thin films by direct current electrodeposition. Mater Lett 274:127991. https://doi.org/10.1016/j.matlet.2020.127991

Lin S-C, Chen S-Y, Chen Y-T, Cheng S-Y (2008) Electrochemical fabrication and magnetic properties of highly ordered silver–nickel core-shell nanowires. J Alloys Compd 449:232–236

Jeon Y, Choe S, Kim HC, Kim MJ, Kim JJ (2019) Electrodeposition of Cu-Ag films in ammonia-based electrolyte. J Alloys Compd 775:639–646. https://doi.org/10.1016/j.jallcom.2018.10.023

Roy MK, Nambissan PMG, Verma HC (2002) Structural, thermal stability and defect studies of Fe–Ag alloy prepared by electrodeposition technique. J Alloys Compd 345:183–188. https://doi.org/10.1016/S0925-8388(02)00480-2

Dadvand N, Dadvand M (2014) Pulse Electrodeposition of Nanostructured silver-tungsten-cobalt oxide composite from a non-cyanide plating bath. J Electrochem Soc 161:D730–D735. https://doi.org/10.1149/2.0371414jes

Han C, Liu Q, Ivey DG (2009) Electrochemical composite deposition of Sn–Ag–Cu alloys. Mater Sci Eng B 164:172–179. https://doi.org/10.1016/j.mseb.2009.09.012

Li Z, Song H, Yang Z, Jin Y, Jiao Z, Zhang Y, Gao Y, Yu Z, Li W, Gong M, Sun X (2009) Synthesis of silver nanowires via electroplating technology and its surface enhanced Raman scattering effect. Appl Surf Sci 255:8571–8574. https://doi.org/10.1016/j.apsusc.2009.06.022

Lu Y, Liang Q, Li W (2013) Fabrication of copper/modal fabric composites through electroless plating process for electromagnetic interference shielding. Mater Chem Phys 140:553–558

Liu Z-C, He Q-G, Xiao P-F, Liang B, Tan J-X, He N-Y, Lu Z-H (2003) Self-assembly monolayer of mercaptopropyltrimethoxysilane for electroless deposition of Ag. Mater Chem Phys 82:301–305

Chua ST, Siow KS (2016) Microstructural studies and bonding strength of pressureless sintered nano-silver joints on silver, direct bond copper (DBC) and copper substrates aged at 300 C. J Alloys Compd 687:486–498

Wu CP, Yi DQ, Li J, Xiao LR, Wang B, Zheng F (2008) Investigation on microstructure and performance of Ag/ZnO contact material. J Alloys Compd 457:565–570

Chen D, Kang Z, Hirahara H, Li W (2019) Quasi layer by layer spray deposition of high-quality Ag coatings with excellent micro mechanical properties. Appl Surf Sci 481:1213–1219. https://doi.org/10.1016/j.apsusc.2019.03.254

Khollari MAR, Ghorbani M, Afshar A (2019) Fabrication and characterization of TiO2 deposited black electroless Ni-P solar absorber. Appl Surf Sci 496:143632. https://doi.org/10.1016/j.apsusc.2019.143632

Muzychenko DA, Schouteden K, Panov VI, Van Haesendonck C (2012) Formation of Co/Ge intermixing layers after Co deposition on Ge (111) \(2\times1\) surfaces. Nanotechnology. 23:435605. https://doi.org/10.1088/0957-4484/23/43/435605

Nakamura Y, Masada A, Cho S-P, Tanaka N, Ichikawa M (2007) Epitaxial growth of ultrahigh density Ge 1–x Sn x quantum dots on Si (111) substrates by codeposition of Ge and Sn on ultrathin SiO 2 films. J Appl Phys 102:124302. https://doi.org/10.1063/1.2822271

Nath P, Chopra KL (1979) Electrical resistivity and thermoelectric power of copper-germanium films. Thin Solid Films 58:339–343

Goeller PT, Boyanov BI, Sayers DE, Nemanich RJ (1997) Structure and stability of cobalt-silicon-germanium thin films, Nucl instruments methods. Phys Res Sect B Beam Interact with Mater Atoms 133:84–89

Zhao F, Xu Y, Mibus M, Zangari G (2017) The Induced electrochemical codeposition of Cu-Ge alloy films. J Electrochem Soc 164:D354–D361. https://doi.org/10.1149/2.1241706jes

Ye X, Celis JP, De Bonte M, Roos JR (1994) Ductility and crystallographic structure of zinc foils electrodeposited from acid zinc sulfate solutions. J Electrochem Soc 141:2698–2708

Offoiach R, Lekka M, Lanzutti A, De Leitenburg C, Fedrizzi L (2017) Production and microstructural characterization of Ni matrix composite electrodeposits containing either micro-or nano-particles of Al. Surf Coat Technol 309:242–248

Williamson GK, Hall WH (1953) X-ray line broadening from filed aluminium and wolfram. Acta Metall 1:22–31

Wojciechowski J (2017) Nickel coatings electrodeposited from watts type baths containing quaternary ammonium sulphate salts. Int J Electrochem Sci 12:3350–3360. https://doi.org/10.20964/2017.04.70

Cotell CM, Sprague JA, Smidt FA (1994) ASM Handbook: Surface Engineering. ASM international, Cleveland

Carrano RV, Mondillo RA, Stern Leach Co (2000) Tarnish-resistant hardenable fine silver alloys. US Patent 6,139,652. https://patents.google.com/patent/US6139652A/en

Brenner A (2013) Electrodeposition of alloys: principles and practice. Elsevier. https://books.google.com/books?hl=en&lr=&id=asA3BQAAQBAJ&oi=fnd&pg=PP1&dq=Brenner+Abner,.+Electrodeposition+of+alloys.&ots=DyfcA2DYe&sig=biIpMJk9WxIxHnDTrkqvmuU6sFc#v=onepage&q=Brenner%20Abner%2C.%20Electrodeposition%20of%20alloys.&f=false

Brenner A, Senderoff S (1964) Electrodeposition of alloys. New York. https://www.sciencedirect.com/book/9781483198071/electrodeposition-of-alloys

Natarajan SR (1985) Current efficiency and electrochemical equivalent in an electrolytic process. Bull Electrochem 1:215–216

Lippincott ER, Van Valkenburg A, Weir CE, Bunting EN (1958) Infrared studies on polymorphs of silicon dioxide and germanium dioxide. J Res Natl Bur Stand 61:61–70

Miller FA, Wilkins CH (1952) Infrared spectra and characteristic frequencies of inorganic ions. Anal Chem 24:1253–1294

Munajad A, Subroto C (2018) Fourier transform infrared (FTIR) spectroscopy analysis of transformer paper in mineral oil-paper composite insulation under accelerated thermal aging. Energies 11(2):364. https://doi.org/10.3390/en11020364

Kumaraguru S, Pavulraj R, Vijayakumar J, Mohan S (2017) Electrodeposition of cobalt/silver multilayers from deep eutectic solvent and their giant magnetoresistance. J Alloys Compd 693:1143–1149

Łukaszewski M, Klimek K, Czerwiński A (2009) Microscopic, spectroscopic and electrochemical characterization of the surface of Pd–Ag alloys. J Electroanal Chem 637:13–20

Tai C-C, Su F-Y, Sun I-W (2005) Electrodeposition of palladium–silver in a Lewis basic 1-ethyl-3-methylimidazolium chloride-tetrafluoroborate ionic liquid. Electrochimica acta 50:5504–5509

Méndez-Albores A, González-Arellano SG, Reyes-Vidal Y, Torres J, Talu S, Cercado B, Trejo G (2017) Electrodeposited chrome/silver nanoparticle (Cr/AgNPs) composite coatings: characterization and antibacterial activity. J Alloys Compd 710:302–311

Dugdale JS (2016) The electrical properties of metals and alloys. Courier Dover Publications, NewYork

Cullity BD, Stock SR (2001) Elements of X-ray diffraction. Prentice hall, New Jersey

Lahiri A, Borisenko N, Borodin A, Olschewski M, Endres F (2016) Characterisation of the solid electrolyte interface during lithiation/delithiation of germanium in an ionic liquid. Phys Chem Chem Phys 18:5630–5637

Zhang R, Iwasaki T, Taoka N, Takenaka M, Takagi S (2011) Impact of GeOx interfacial layer thickness on Al2O3/Ge MOS interface properties. Microelectron Eng 88:1533–1536

Nigam A, Kala S (2020) Optical, structural and XPS studies of Ag nanoparticles prepared via Melia azedarach plant extract. In: AIP Conf Proc, 2020: 20116

Panafidin MA, Bukhtiyarov AV, Prosvirin IP, Chetyrin IA, Bukhtiyarov VI (2018) Model bimetallic Pd–Ag/HOPG catalysts: an XPS and STM study. Kinet Catal 59:776–785

Abu-Safe HH, Al-Esseili R, El-Nasser H, Sarollahi M, Refaei M, Zamani-Alavijeh M, Naseem H, Ware ME (2020) Au–Ag–Al Nano-Alloy Thin films as an advanced material for photonic applications: XPS analysis, Linear and nonlinear optical properties under CW regime. Cryst Res Technol. https://doi.org/10.1002/crat.201900228

Chevalier P-Y (1988) Critical assessment of thermodynamic data for the Ag-Ge system. Thermochimica acta 130:25–32

Akhmetova AM, Dinsdale AT, Khvan AV, Cheverikin VV, Kondratyev AV, Ivanov DO (2015) Compounds, experimental investigations of the Ag–Cu–Ge system. J Alloys Compd 630:84–93

Wang J, Liu YJ, Tang CY, Liu LB, Zhou HY, Jin ZP (2011) Thermodynamic description of the Au–Ag–Ge ternary system. Thermochimica acta 512:240–246

Filipponi A, Giordano VM, Malvestuto M (2002) Lattice expansion and Ge solubility in the Ag1–ϑGeϑ terminal solid solution. Physica Status Solidi 234:496–505

Briggs TR, McDuffie RO, Willisford LH (2002) Germanium. XXXI. alloys of Germanium: Silver-Germanium. J Phys chem 33:1080–1096

Ren F, Yin L, Wang S, Volinsky AA, Tian B (2013) Cyanide-free silver electroplating process in thiosulfate bath and microstructure analysis of Ag coatings. Trans Nonferr Met Soc China 23:3822–3828. https://doi.org/10.1016/s1003-6326(13)62935-0

Nasehnejad M, Shahraki MG, Nabiyouni G (2016) Atomic force microscopy study, kinetic roughening and multifractal analysis of electrodeposited silver films. Appl Surf Sci 389:735–741

Wang SK, Kita K, Lee CH, Tabata T, Nishimura T, Nagashio K, Toriumi A (2010) Desorption kinetics of GeO from GeO 2/Ge structure. J Appl Phys 108:54104. https://doi.org/10.1063/1.3475990

Jones DA (1992) Principles and prevention of corrosion. Macmillan. https://cds.cern.ch/record/24506710.1007/s10853-020-05601-7

Chen YH, Liu WC, Lin YC, Chung CC, Zeng WJ, Chu WJ, Chung TY, Liu CY (2016) Sulfurization study on the Ag and Ag-Pd reflectors for GaN-based LEDs. J Electron Mater 45:191–196

Elliott RP, Shunk FA (1980) The Ag- Ge system (Silver-Germanium). Bull Alloy Ph Diagr 1:47–51

Acknowledgements

Special thanks goes to Mohammad Hossein Yari for his great support and kind help. The authors would also like to thank Tarbiat Modares University for the financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

None.

Additional information

Handling Editor: David Balloy.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bahmani, E., Zakeri, A. & Sabour Rouh Aghdam, A. Microstructural analysis and surface studies on Ag-Ge alloy coatings prepared by electrodeposition technique. J Mater Sci 56, 6427–6447 (2021). https://doi.org/10.1007/s10853-020-05601-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05601-7