Abstract

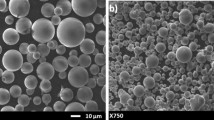

In order to improve corrosion resistance of the 316L stainless steel in liquid zinc, four different kinds of TiAl–Nb coatings were deposited by high velocity oxygen fuel spraying. The results indicated that the TiAl–Nb coatings have dense and uniform microstructure and good mechanical properties. The TiAl–Nb coatings exhibit excellent corrosion resistance. Four different kinds of TiAl–Nb coatings have a incubation time, which do react with liquid zinc. The Ti28.15Al63.4Nb8.25Y0.2 coating possesses the longest lifetime, which can reach up to 1080 h. The TiAl–Nb coatings can provide a long-term corrosion protection for 316L stainless steel. The Al content has an important effect on the corrosion resistance of the coating, and the addition of the Y element may benefit the corrosion resistance to some extent. The corrosion process of the coating consists of the following steps: physical barrier of the TiAl–Nb coatings (incubation period), the corrosion of bond coat and the failure of the coatings.

Similar content being viewed by others

References

Han XL, Dou WW, Chen SG, Zhu SD, Pu YN, Li H, Wang W, Li W (2020) Stable slippery coating with structure of tubes and pyramids for inhibition of corrosion induced by microbes and seawater. Sur Coat Technol 388:125596

Zhang CL, Zhang F, Song L, Zeng RC, Li SQ, Han EH (2017) Corrosion resistance of a superhydrophobic surface on micro-arc oxidation coated Mg-Li-Ca alloy. J Alloys Compd 728:815–826

Gupta A, Srivastava C (2019) Correlation between microstructure and corrosion behaviour of SnBi-graphene oxide composite coatings. Sur Coat Technol 375:573–588

LeBozec N, Thierry D, Persson D, Riener CK, Luckeneder G (2019) Influence of microstructure of zinc-aluminium-magnesium alloy coated steel on the corrosion behavior in outdoor marine atmosphere. Surf Coat Technol 374:897–909

Bandyopadhyay N, Jha G, Singh AK, Rout TK, Rani N (2006) Solar energy protects steels against corrosion: Enhanced protection capability achieved by NiFeO decorated BiVO4 photoanode. Surf Coat Technol 200:4312–4319

Ajersch F, Llinca F, Goodwin FE (2005) Numerical simulation of flow, temperature and composition variations in a galvanizing bath. Can Metall Q 44:369–378

Wang WJ, Lin JP, Wang YL, Chen GL (2007) The corrosion of intermetallic alloys in liquid zinc. J Alloys Compd 428:237–243

Liu XB, Barbero E, Xu J, Burris M, Chang K, Sikka V (2005) Liquid metal corrosion of 316L, Fe3Al, and FeCrSi in molten Zn-Al baths. Metall Mater Trans A 36:2049–2058

Sun PF, Hu YF, Lin JP (2013) Isothermal corrosion behaviors of TiAl–Nb alloys in liquid Zn-55Al-1.6Si (wt. %). Mater Sci Forum 747–748:69–76

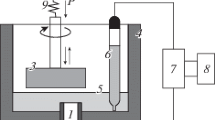

Puddu P, Popa S, Bolelli G, Krieg P, Lassinantti Gualtieri M, Lusvarghi L, Killinger A, Gadow R (2018) Suspension HVOF spraying of TiO2 using a liquid-fueled torch. Surf Coat Technol 349:677–694

Vernhes L, Lee DA, Poirier D, Li D, Klemberg-Sapieha JE (2013) HVOF coating case study for power plant process control ball valve application. J Therm Spray Technol 22:1184–1192

Matthews S, James B (2010) Review of thermal spray coating applications in the steel industry: Part 2-Zinc pot hardware in the continuous galvanizing line. J Therm Spray Technol 19:1277–1286

Vuoristo PMJ (2007) High velocity sprays boost hardmetal industrial coatings. Met Powder Rep 62:22–29

Pougoum F, Martinu L, Desjardins P, Klemberg-Sapieha J, Gaudet S, Savoie S, Schulz R (2016) Effect of high-energy ball-milling on the characteristics of Fe3Al-based HVOF coatings containing boride and nitride phases. Wear 358–359:97–108

Seong BG, Kim MC, Kim KY (2001) Reaction of WC-Co coating with molten zinc in a zinc pot of a continuous galvanizing line. Surf Coat Technol 138:101–110

Tomoki T, Kazumi T, Yoshihumi K, Yasuyuki T (1993) Durability of Sprayed WC/Co Coatings in Al-added Zinc Bath. Trans Iron Steel Inst Jpn 79:1095–1100

Chen X, Zhang RY (2012) Corrosion behavior of low pressure plasma sprayed MoB/CoCr coatings exposed to molten Al-12.07wt.%Si alloy. Procedia Eng 27:1766–1773

Zhang JF, Deng CM, Song JB, Deng CG, Liu M, Zhou KS (2013) MoB–CoCr as alternatives to WC–12Co for stainless steel protective coating and its corrosion behavior in molten zinc. Surf Coat Technol 235:811–818

Ye T, Song L, Gao SB, Liang YF, Wang YL, Lin JP (2017) Precipitation behavior of the ωo phase in an annealed high Nb-TiAl alloy. J Alloys Compd 701:882–891

Yang L, Chai LH, Wang YL, Gao SB, Song L, Lin JP (2015) Precipitates in high-Nb TiAl alloyed with Si. Mat Lett 154:8–11

Fang L, Lin JP, Liang YF, Zhang LQ, Yin J, Ding XF (2016) Microstructural instability in surface layer of a high Nb-TiAl alloy processed by shot peening following high temperature exposure. Intermetallics 78:8–16

Liu GH, Wang ZD, Fu TL, Li Y, Liu HT, Li TR, Gong MN, Wang GD (2015) Study on the microstructure, phase transition and hardness for the TiAl–Nb alloy design during directional solidification. J Alloys Compd 650:45–52

Zeng HJ, Lin JP, He XY (2012) Influence of bond coats on the microstructure and mechanical behaviors of TiAlNb coating prepared by HVOF-spraying. J Therm Spray Technol 211:245–1256

Wang WJ, Lin JP, Wang YL, Zhang Y, Chen GL (2007) Isothermal corrosion TiAl–Nb alloy in liquid zinc. Mater Sci Eng: A 452–453:194–201

Zeng HJ, Zhang LQ, Lin JP, Zhang SJ, Chen GL (2011) TiAlNb intermetallic compound coating prepared by high velocity oxy-fuel spraying. Sur Coat Technol 206:178–184

Zhao LL, Lin JP, Zhang LQ, Wang YL, Ye F, Chen GL (2009) Influence of Al, Nb on the high temperature oxidation resistance of high Nb containing TiAl alloy. J Mater Eng 1:126–130

Sun PF, Zhang LQ, Zhang L, Lin JP (2012) Improvement in the liquid zinc corrosion resistance of high Nb-TiAl alloys by pre-oxidation in a SiO2-powder pack. Sci China: Technol Sci 55:505–509

Ozgul K, Gokcen A, Osman TI (2003) The role of parameters in plasma assisted vapor deposition of tin/tin-oxide coatings. Sur Coat Technol 172:166–175

Buta SS, Puri D, Prakash S (2005) Mechanical and metallurgical properties of plasma sprayed and laser remelted Ni-20Cr and Stellite-6 coatings. J Mater Process Technol 159:347–355

Hazoor SS, Buta SS, Prakash S (2006) Mechanical and microstructural properties of HVOF sprayed WC-Co and Cr3C2-NiCr coatings on the boiler tube steels using LPG as the fuel gas. J Mater Process Technol 171:77–82

Zhao LL, Li GY, Zhang LQ, Lin JP, Song XP, Ye F, Chen GL (2010) Influence of Y addition on the long time oxidation behaviors of high Nb containing TiAl alloys at 900 °C. Intermetallic 18:1586–1596

Vassilev GP, Tedenac JC (2000) Thermodynamic optimization of the Ni-Zn system. J Phase Equilib Diffus 21:287–301

Zhang K, Tang NY, Frank ED (2007) Reaction of 316L stainless steel with a galvanizing bath. J Mater Sci 42:9736–9745

Teixeira V (2002) Residual stress and cracking in thin PVD coatings. Vacuum 64:393–399

Acknowledgements

This work was supported by the Nation Natural Science Foundation of China (No. 51871012); Beijing Municipal Natural Science Foundation (No. 2162024); Fundamental Research Funds for the Central Universities (No. FRF-GF-19-023B).

Author information

Authors and Affiliations

Corresponding author

Additional information

Handling Editor: David Balloy.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, C., Zhang, L., Huang, Q. et al. Corrosion resistance of TiAl–Nb coating on 316L stainless steel in liquid zinc. J Mater Sci 56, 4022–4033 (2021). https://doi.org/10.1007/s10853-020-05497-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05497-3