Abstract

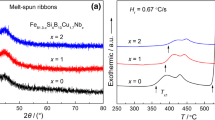

The effects of annealing temperature and heating rate on the microstructure, magnetic, and mechanical properties of melt-spun Fe81.7−xSi4B13Cu1.3Nbx (x = 0–4) alloy ribbons have been investigated. With increasing the annealing temperature, a ductile–brittle transition occurs during amorphous structure relaxation, the brittleness becomes severe with more α-Fe precipitation, and the hardness rises continuously. After annealing at respective optimum temperatures under the heating rate of 20 K/min, as the Nb content increases from 0 to 4 at.%, average grain size (Dα-Fe) and volume fraction (Vα-Fe) of the α-Fe in the nanocrystalline alloys decrease gradually from 53.3 nm and 52% to 8.7 nm and 42%, respectively; the strain at fracture (εf) representing ductile level increases from 1.33 to 1.72%; and the coercivity (Hc), saturation magnetic flux densities (Bs), and Vickers hardness (Hv) all decrease gradually. As the heating rate rises from 10 to 400 K/min, the Dα-Fe of the Fe81.7Si4B13Cu1.3 alloy decreases from 45.7 to 28.4 nm without considerable variation of the Vα-Fe; the Hc lowers from 235 to 25 A/m, the εf increases from 1.10 to 1.66%, and the Bs and Hv change slightly. Enriching of Nb weakens the dependence of nanostructure, magnetic softness, and annealing embrittlement on the heating rate. A correlation of εf ∝ Dα-Fen is found for the nanocrystalline alloys, where the n rises from − 1 to − 1/2 with enriching of Nb from 0 to 4 at.%. The mechanisms by which nanostructure affects magnetic and mechanical properties have been discussed.

Similar content being viewed by others

References

McHenry ME, Willard MA, Laughlin DE (1999) Amorphous and nanocrystalline materials for applications as soft magnets. Prog Mater Sci 44:291–433

Herzer G (2013) Modern soft magnets: amorphous and nanocrystalline materials. Acta Mater 61:718–734

Petzold J (2002) Advantages of soft magnetic nanocrystalline materials for modern electronic applications. J Magn Magn Mater 242–245:84–89

Yoshizawa Y, Oguma S, Yamauchi K (1988) New Fe-based soft magnetic alloys composed of ultrafine grain structure. J Appl Phys 64:6044–6046

Ohta M, Yoshizawa Y (2007) New high-Bs Fe-based nanocrystalline soft magnetic alloys. Jpn J Appl Phys 46:L477–L479

Li YH, Jia XJ, Xu YQ, Chang CT, Xie GQ, Zhang W (2017) Soft magnetic Fe–Si–B–Cu nanocrystalline alloys with high Cu concentrations. J Alloys Compd 722:859–863

Makino A, Kubota T, Yubuta K, Inoue A, Matsumoto H, Yoshida S (2011) Low core losses and magnetic properties of Fe85–86Si1–2B8P4Cu1 nanocrystalline alloys with high Bs for power applications. J Appl Phys 109(7):07A302-1–07A302-5

Shurygina NA, Glezer AM, Permyakova IE, Blinova EN (2012) Effect of nanocrystallization on the mechanical and magnetic properties of Finemet-type alloy (Fe73.5Si13.5B9Nb3Cu1). Bull Russ Acad Sci Phys 76:44–50

Um CY, Johnson F, Simone M, Barrow J, McHenry ME (2005) Effect of crystal fraction on hardness in FINEMET and NANOPERM nanocomposite alloys. J Appl Phys 97:10F504–1–10F504-3

Škorvánek I, Švec P, Grenèche J-M, Kovác J, Marcin J, Gerling R (2002) Influence of microstructure on the magnetic and mechanical behaviour of amorphous and nanocrystalline FeNbB alloy. J Phys Condens Matter 14:4717–4736

Sun YY, Song M, Liao XZ, Sha G, He YH (2002) Effects of isothermal annealing on the microstructures and mechanical properties of a FeCuSiBAl amorphous alloy. Mater Sci Eng A 543:145–151

Gavrilović A, Rafailović LD, Minić DM, Wosik J, Angerer P, Minić DM (2011) Influence of thermal treatment on structure development and mechanical properties of amorphous Fe735Cu1Nb3Si155B7 ribbon. J Alloys Compd 509S:S119–S122

Škorvánek I, Gerling R (1992) The influence of neutron irradiation on the soft magnetic and mechanical properties of amorphous and nanocrystalline Fe735Cu1Nb3Si135B9 alloys. J Appl Phys 72:3417–3422

Koch CC, Malow TR (1999) The ductility problem in nanocrystalline materials. Mater Sci Forum 312–314:565–574

Minnert C, Kuhnt M, Bruns S, Marshal A, Pradeep KG, Marsilius M, Bruder E, Durst K (2018) Study on the embrittlement of flash annealed Fe852B95P4Cu08Si05 metallic glass ribbons. Mater Design 156:252–261

Komatsu T, Matusita K, Yokota R (1985) Structural relaxation and embrittlement in Fe-Ni based metallic glasses. J Mater Sci 20:1375–1382. https://doi.org/10.1007/BF01026335

Wu TW, Spaepen F (1990) The relation between embrittlement and structural relaxation of an amorphous metal. Philos Mag B 61:739–750

Gerling R, Schimansky FP (1988) R Wagner Two-stage embrittlement of amorphous Fe40Ni40P20 resulting from a loss of free volume and phase separation. Acta Metall 36:575–583

Kumar G, Ohnuma M, Furubayashi T, Ohkubo T, Hono K (2008) Thermal embrittlement of Fe-based amorphous ribbons. J Non-Cryst Solids 354:882–888

Škorvánek I, Duhaj P, Kovác J, Kavečanský V, Gerling R (1997) Influence of microstructure on magnetic and mechanical behavior in amorphous and nanocrystalline Fe735Nb45Cr5CulB16 alloy. Mater Sci Eng A 226–228:218–222

Jia XJ, Li YH, Wu LC, Zhang W (2020) A study on the role of Ni content on structure and properties of Fe-Ni-Si-B-P-Cu nanocrystalline alloys. J Alloys Compd 822:152784–1–152784-6

Wu LC, Li YH, Yubuta K, He AN, Zhang Y, Zhang W (2020) Optimization of the structure and soft magnetic properties of a Fe87B13 nanocrystalline alloy by additions of Cu and Nb. J Magn Magn Mater 497:166001–1–166001-6

Sharma P, Zhang X, Zhang Y, Makino A (2015) Competition driven nanocrystallization in high Bs and low coreloss Fe–Si–B–P–Cu soft magnetic alloys. Scripta Mater 95:3–6

Jia XJ, Li YH, Wu LC, Zhang Y, Xie L, Zhang W (2019) The role of Cu content on structure and magnetic properties of Fe–Si–B–P–Cu nanocrystalline alloys. J Mater Sci 54:4400–4408. https://doi.org/10.1007/s10853-018-3131-5.

Farkas D, Hyde B (2005) Improving the ductility of nanocrystalline bcc metals. Nano Lett 5:2403–2407

Yang F, Yang W (2009) Crack growth versus blunting in nanocrystalline metals with extremely small grain size. J Mech Phys Solids 57:305–324

Daniil M, Ohodnicki PR, McHenry ME, Willard MA (2010) Shear band formation and fracture behavior of nanocrystalline (Co, Fe)-based alloys. Philos Mag 90:1547–1565

Wu C, Chen HP, Lv HP, Yan M (2016) Interplay of crystallization, stress relaxation and magnetic properties for FeCuNbSiB soft magnetic composites. J Alloy Compd 673:278–282

Senkov ON, Miracle DB (2001) Effect of the atomic size distribution on glass forming ability of amorphous metallic alloys. Mater Res Bull 36:2183–2198

Takeuchi A, Inoue A (2005) Classification of bulk metallic glasses by atomic size difference, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater Trans 46:2817–2829

Wang WH (2007) Roles of minor additions in formation and properties of bulk metallic glasses. Prog Mater Sci 52:540–595

Hono K (2002) Nanoscale microstructural analysis of metallic materials by atom probe field ion microscopy. Prog Mater Sci 47:621–729

Kissinger HE (1957) Reaction kinetics in differential thermal analysis. Anal Chem 29:1702–1706

Glezer AM, Manaenkov SE, Permyakova IE, Shurygina NA (2011) Effect of nanocrystallization on the mechanical behavior of amorphous Fe-Ni-based alloys. Russ Metall 2011:947–955

Zielinski PG, Ast DG (1984) Yield and reformation of metallic glasses strengthened by post-extrusion addition of second phase particles. Acta Metall 32:397–405

Donald IW, Davies HA (1980) The influence of transition metal substitutions on the formation, stability and hardness of some Fe and Ni-based metallic glasses. Philo Mag A 42:277–293

Suzuki K, Herzer G (2012) Magnetic-field-induced anisotropies and exchange softening in Fe-rich nanocrystalline soft magnetic alloys. Scripta Mater 67:548–553

Ohta M, Yoshizawa Y (2009) High Bs nanocrystalline Fe84−x−yCuxNbySi4B12 alloys (x=0.0–1.4, y=0.0–2.5). J Magn Magn Mater 321:2220–2224

Wang AD, Zhao CL, He AN, Men H, Chang CT, Wang XM (2016) Composition design of high Bs Fe-based amorphous alloys with good amorphous-forming ability. J Alloys Compd 656:729–734

Acknowledgements

This work was supported by the National Key Research and Development Program of China [Grant Number 2017YFB0903903]; the National Natural Science Foundation of China [Grant Numbers 51571047, 51771039]; and the Fundamental Research Funds for the Central Universities [Grant Number DUT20JC12].

Author information

Authors and Affiliations

Contributions

YHL contributed to formal analysis, writing—review and editing. GZZ contributed to investigation, writing—original draft. LCW contributed to investigation. WZ contributed to supervision, writing—review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Handling Editor: P. Nash.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, Y., Zhang, G., Wu, L. et al. Effects of annealing temperature and heating rate on microstructure, magnetic, and mechanical properties of high-Bs Fe81.7−xSi4B13NbxCu1.3 nanocrystalline alloys. J Mater Sci 56, 2572–2583 (2021). https://doi.org/10.1007/s10853-020-05341-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05341-8