Abstract

In this work, we prepared the biomass castor oil-based rigid polyurethane foams (RPUF). The two bio-based RPUFs contain modified polyols from castor oil, one of which was transamidated castor oil with diethanolamine (BIO1) and another was further modified epoxidized polyols in BIO1 with phenylphosphonic acid. The cellular structure, thermal, flame retardant and mechanical properties of RPUF via incorporation of expandable graphite (EG) and graphene oxide (GO) on a total fixed amount of 6 wt% were studied by scanning electron microscopy (SEM), thermal conductivity, limiting oxygen index (LOI), vertical burning test (UL94) and cone calorimeter test (CCT), etc. The cellular structure indicated that GO facilitates the dispersion of EG and decreases the cell size of the foam. The thermal and fire behaviors indicated that GO increased the insulation capacity and the flame-retardant performance of RPUFs. The optimal sample BIO2/EG/GO obtained V-0 rating, whereas BIO2/EG obtained only V-2 rating on the UL94 test. Moreover, results from CCT showed that the BIO2/EG/GO effectively reduced heat release rate (HRR), total heat release (THR) and total smoke production (TSP) by 54%, 24% and 15%, respectively, in comparison with BIO1 and decreased the HRR and THR 46% and 6%, respectively, compared to BIO2 sample. The compressive performance of BIO2/EG/GO and BIO2/EG increased to 0.11 MPa compared to 0.07 MPa from BIO1. These interesting results proved a new strategy to develop a bio-based flame-retardant RPUF as fire safety thermal insulation materials by incorporating natural-based carbon materials.

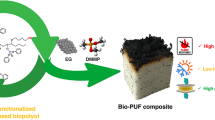

Graphic abstract

Similar content being viewed by others

References

Levchik SV, Weil ED (2004) Polym Int 53:1585–1610

Wang S, Qian L, Xin F (2016) Polym Compos 39:329–336

Luo W, Qin J, Xiao M, Han D, Wang S, Meng Y (2017) ACS Omega 2:3205–3213

Gaidukova G, Ivdre A, Fridrihsone A, Verovkins A, Cabulis U, Gaidukovs S (2017) Ind Crops Prod 102:133–143

Mutlu H, Meier MAR (2010) Eur J Lipid Sci Technol 112:10–30

Wang C, Zheng Y, Xie Y, Qiao K, Sun Y, Yue L, J Polym Res. https://doi.org/10.1007/s10965-015-0782-7

Ionescu M, Petrović ZS, Wan X (2008) J Am Oil Chem Soc 85:465–473

Stirna U, Lazdiņa B, Vilsone D, Lopez MJ, Vargas-Garcia MdelC, Suárez-Estrella F, Moreno J (2012) J Cell Plast 48:476–488

Zhang L, Zhang M, Hu L, Zhou Y (2014) Ind Crops Prod 52:380–388

Ding H, Huang K, Li S, Xu L, Xia J, Li M (2017) J Anal Appl Pyrolysis 128:102–113

Rabe S, Chuenban Y, Schartel B (2017) Materials (Basel) 10:455

Rao WH, Zhu ZM, Wang SX, Wang T, Tan Y, Liao W, Zhao HB, Wang YZ (2018) Polym Degrad Stab 153:192–200

Yuan Y, Ma C, Shi Y, Song L, Hu Y, Hu W (2018) Mater Chem Phys 211:42–53

Gosz K, Haponiuk J, Piszczyk Ł (2018) J Polym Environ 26:3877–3888

Camino G, Duquesne S, Delobel R, Eling B, Lindsay C, Roels T, ACS Symp Ser https://doi.org/10.1021/bk-2001-0797.ch008

Thirumal M, Khastgir D, Singha NK, Manjunath BS, Naik YP (2008) J Appl Polym Sci 110:2586–2594

Wang X, Kalali EN, Wan J-T, Wang D-Y (2017) Prog Polym Sci 69:22–46

Strankowski M, Korzeniewski P, Strankowska J, Anu AS, Thomas S. Materials (Basel)., https://doi.org/10.3390/ma11010082

Wu N, She X, Yang D, Wu X, Su F, Chen Y (2012) J Mater Chem 22:17254

Bera M, Chandravati P, Gupta P, Maji PK (2018) J Nanosci Nanotechnol 18:902–912

Marcano DC, Kosynkin DV, Berlin JM, Sinitskii A, Sun Z, Slesarev AS, Alemany LB, Lu W, Tour JM (2018) ACS Nano 12:2078

Bera M, Maji PK (2017) Polymer (Guildf) 119:118–133

Lorenzetti A, Roso M, Bruschetta A, Boaretti C, Modesti M (2016) Polym Adv Technol 27:303–307

Pokharel P, Choi S, Lee DS (2015) Compos Part A Appl Sci Manuf 69:168–177

Liu H, Dong M, Huang W, Gao J, Dai K, Guo J, Zheng G, Liu C, Shen C, Guo Z (2017) J Mater Chem C 5:73–83

Zhou S, Hao G, Zhou X, Jiang W, Wang T, Zhang N, Yu L (2016) Chem Eng J 302:155–162

Kim J-M, Kim J-H, Ahn J-H, Kim J-D, Park S, Park KH, Lee J-M (2018) Compos Part B Eng 136:28–38

Jiang S, He Z, Li Q, Wang J, Wu G, Zhao Y, Kang M (2019) Polym Compos 40:E953–E961

Ionescu M (2005) Chemistry and technology of polyols for polyurethanes, Rapra Technology

Yakushin V, Stirna U, Bikovens O, Misane M, Sevastyanova I, VilsoneD. Mater Sci, https://doi.org/10.5755/j01.ms.20.3.4532

Bellamy LJ (1975) The infra-red spectra of complex molecules, 1st edn. Springer, Netherlands

Jia PY, Bo CY, Zhang LQ, Hu LH, Zhang M, Zhou YH (2015) J Ind Eng Chem 28:217–224

Sinadinović-Fišer S, Janković M, Borota O (2012) Chem Eng Process Process Intensif 62:106–113

Jia P, Hu L, Zhang M, Feng G, Zhou Y (2017) Eur Polym J 87:209–220

Sun F, Yu T, Hu C, Li Y (2016) Compos Sci Technol 136:76–84

Yu B, Wang X, Qian X, Xing W, Yang H, Ma L, Lin Y, Jiang S, Song L, Hu Y, Lo S (2014) RSC Adv 4:31782

Yuan R, Yuan J, Wu Y, Chen L, Zhou H, Chen J (2017) Appl Surf Sci 416:868–877

Saha MC, Kabir ME, Jeelani S (2008) Mater Sci Eng, A 479:213–222

Guo Y, Bao C, Song L, Yuan B, Hu Y (2011) Ind Eng Chem Res 50:7772–7783

Ying Z, Lin X, Qi Y, Luo J (2008) Mater Res Bull 43:2677–2686

Cai D, Jin J, Yusoh K, Rafiq R, Song M (2012) Compos Sci Technol 72:702–707

Pokharel P, Lee DS (2014) Chem Eng J 253:356–365

Ji D, Fang Z, He W, Luo Z, Jiang X, Wang T, Guo K (2015) Ind Crops Prod 74:76–82

Hu XM, Wang DM (2013) J Appl Polym Sci 129:238–246

Zhang L, Zhang M, Zhou Y, Hu L (2013) Polym Degrad Stab 98:2784–2794

Li Y, Zou J, Zhou S, Chen Y, Zou H, Liang M, Luo W (2014) J Appl Polym Sci 131:1–9

Pokharel P, Lee SH, Lee DS (2015) J Nanosci Nanotechnol 15:211–214

Estravís S, Tirado-Mediavilla J, Santiago-Calvo M, Luis-Ruiz-Herrero J, Villafañe F, Ángel-Rodríguez-Pérez M (2016) Eur Polym J 80:1–15

Choi SW, Jung JM, Yoo HM, Kim SH, Il-Lee W (2018) J Therm Anal Calorim 132:1253–1262

Acuña P, Santiago-Calvo M, Villafañe F, Rodríguez-Perez MA, Rosas J, Wang DY (2018) Polym Compos 40:E1705–E1715

Mosiewicki MA, Dell’Arciprete GA, Aranguren MI, Marcovich NE (2009) J Compos Mater 43:3057–3072

Zhang C, Kessler MR, Sustain ACS (2015) Chem Eng 3:743–749

Hejna A, Kirpluks M, Kosmela P, Cabulis U, Haponiuk J, Piszczyk Ł (2017) Ind Crops Prod 95:113–125

Duan HJ, Kang HQ, Zhang WQ, Ji X, Li ZM, Tang JH (2014) Polym Int 63:72–83

Gama N, Costa LC, Amaral V, Ferreira A, Barros-Timmons A (2017) Compos Sci Technol 138:24–31

Acuña P, Li Z, Santiago-Calvo M, Villafañe F, Ángel-Rodríguez-Perez M, Wang DY (2019) Polymers (Basel) 11:168

Kim H, Miura Y, Macosko CW (2010) Chem Mater 22:3441–3450

Wang X, Hu Y, Song L, Yang H, Xing W, Lu H (2011) J Mater Chem 21:4222

Santiago-Calvo M, Blasco V, Ruiz C, París R, Villafañe F, Rodríguez-Pérez MÁ (2017) Eur Polym J 97:230–240

Bian J, Lin HL, He FX, Wei XW, Chang I-T, Sancaktar E (2013) Compos Part A Appl Sci Manuf 47:72–82

Bourbigot S, Duquesne S (2007) J Mater Chem 17:2283–2300

Gómez-Fernández S, Günther M, Schartel B, Corcuera MA, Eceiza A (2018) Ind Crops Prod 125:346–359

Modesti M, Lorenzetti A, Besco S, Hrelja D, Semenzato S, Bertani R, Michelin RA. Polym Degrad Stab https://doi.org/10.1016/j.polymdegradstab.2008.08.005

Xu W, Wang G, Zheng X (2015) Polym Degrad Stab 111:142–150

Wang X, Hu Y, Song L, Xuan S, Xing W, Bai Z, Lu H (2011) Ind Eng Chem Res 50:713–720

Lorenzetti A, Dittrich B, Schartel B, Roso M, Modesti M (2017) J Appl Polym Sci 134:1–8

Shi X, Peng X, Zhu J, Lin G, Kuang T (2018) J Colloid Interface Sci 524:267–278

Wang S, Du X, Jiang Y, Xu J, Zhou M, Wang H, Cheng X, Du Z (2019) J Colloid Interface Sci 537:197–205

Chen X, Liu Y, Bai S, Wang Q (2014) Polym Plast Technol Eng 53:1402–1407

Acknowledgements

Special acknowledgments to MORCHEM SA (Barcelona, Spain) for allowing us to use their specific polyurethane facilities to analyze our flame-retardant polyols and isocyanates used in the manuscript.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Handling Editor: Maude Jimenez.

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Acuña, P., Zhang, J., Yin, GZ. et al. Bio-based rigid polyurethane foam from castor oil with excellent flame retardancy and high insulation capacity via cooperation with carbon-based materials. J Mater Sci 56, 2684–2701 (2021). https://doi.org/10.1007/s10853-020-05125-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-05125-0