Abstract

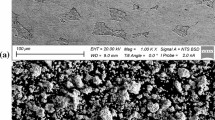

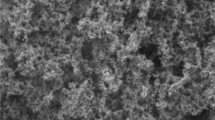

We investigate the mechanisms by which titanium dioxide nanoparticles (nano-TiO2) interact with cement hydration products. To this end, we synthesize nanomodified cement samples with 1 wt% and 5 wt% of TiO2. We investigate the physical properties using depth-sensing-based methods such as statistical nanoindentation and microscopic scratch testing. Fourier transform infrared spectroscopy yields the chemistry, whereas micromechanics modeling provides insights into the nanostructure. The macroscopic plane strain modulus increases by 16% and 83%, respectively, and the macroscopic indentation hardness increases by 37% and 40%, respectively. The fracture toughness rises by 3% and 11%, respectively. Environmental scanning electron microscopy reveals a 30% reduction in crack width for TiO2 cement nanocomposites compared to plain cement. Meanwhile, Fourier transform infrared spectroscopy and statistical deconvolution show an increase in the fraction of high-density calcium silicate hydrates (by 22% and 12%, respectively), and in the fraction of calcium hydroxide (by 101% and 251%, respectively). Within the framework of the colloidal and granular models of C–S–H, the increase in stiffness and strength after nano-TiO2 modification of cement paste is due to the closely packed structure and the high atomic coordination number of high-density C–S–H. Similarly, due to the high dimensional stability of high-density C–S–H and calcium hydroxide, our results explain the reported improvements in drying shrinkage and creep properties following cement modification with nano-TiO2.

Similar content being viewed by others

References

Nazari A, Riahi S, Riahi S, Shamekhi SF, Khademno A (2010) Mechanical properties of cement mortar with Al2O3 nanoparticles. J Am Sci 6(4):94–97

Gaitero JJ, Campillo I, Guerrero A (2008) Reduction of the calcium leaching rate of cement paste by addition of silica nanoparticles. Cem Conc Res 38(8-9):1112–1118. https://doi.org/10.1016/j.cemconres.2008.03.021

Stefanidou M, Papayianni I (2012) Influence of nano-SiO2 on the Portland cement pastes. Comp Part B Eng 43(6):2706–2710. https://doi.org/10.1016/j.compositesb.2011.12.015

Liu J, Li Q, Xu S (2015) Influence of nanoparticles on fluidity and mechanical properties of cement mortar. Constr Build Mater 101:892–901. https://doi.org/10.1016/j.conbuildmat.2015.10.149

Tobon JI, Paya J, Restrepo OJ (2015) Study of durability of Portland cement mortars blended with silica nanoparticles. Constr Build Mater 80:92–97. https://doi.org/10.1016/j.conbuildmat.2014.12.074

Kawashima S, Hou P, Corr DJ, Shah SP (2013) Modification of cement-based materials with nanoparticles. Cem Concr Comp 36:8–15. https://doi.org/10.1016/j.cemconcomp.2012.06.012

Shaikh FUA, Supit SWM, Sarker PK (2014) A study on the effect of nano silica on compressive strength of high volume fly ash mortars and concretes. Mater Des 60:433–442. https://doi.org/10.1016/j.matdes.2014.04.025

Cardenas C, Tobon JI, Garcia C, Vila J (2012) Functionalized building materials: photocatalytic abatement of NOx by cement pastes blended with TiO2 nanoparticles. Constr Build Mater 36:820–825. https://doi.org/10.1016/j.conbuildmat.2012.06.017

Diamanti MV, Del Curto B, Ormellese M, Pedeferri MP (2013) Photocatalytic and self-cleaning activity of colored mortars containing TiO2. Constr Build Mater 46:167–174. https://doi.org/10.1016/j.conbuildmat.2013.04.038

Perez-Nicolas M, Balbuena J, Cruz-Yusta M, Sanchez L, Navarro-Blasco I, Fernandez JM, Alvarez JI (2015) Photocatalytic NOx abatement by calcium aluminate cements modified with TiO2: improved NO2 conversion. Cem Concr Res 70:67–76. https://doi.org/10.1016/j.cemconres.2015.01.011

Nazari A, Riahi S, Riahi S, Shamekhi SF, Khademno A (2010) Assessment of the effects of the cement paste composite in presence TiO2 nanoparticles. Am Sci 6(4):43–46

Chen J, Kou SC, Poon CS (2012) Hydration and properties of nano-TiO2 blended cement composites. Cem Concr Comp 34(5):642–649. https://doi.org/10.1016/j.cemconcomp.2012.02.009

Nazari A, Riahi S (2011) The effects of TiO2 nanoparticles on physical, thermal and mechanical properties of concrete using ground granulated blast furnace slag as binder. Mater Sci Eng A 528(4-5):2085–2092. https://doi.org/10.1016/j.msea.2010.11.070

Feng D, Xie N, Gong C, Leng Z, Xiao H, Li H, Shi X (2013) Portland cement paste modified by TiO2 nanoparticles: a microstructure perspective. Industr Eng Chem Res 52(33):11575–11582. https://doi.org/10.1021/ie4011595

Jalal M, Fathi M, Farzad M (2013) Effects of fly ash and TiO2 nanoparticles on rheological, mechanical, microstructural and thermal properties of high strength self compacting concrete. Mech Mater 61:11–27. https://doi.org/10.1016/j.mechmat.2013.01.010

Wang L, Zhang H, Gao Y (2018) Effect of TiO2 nanoparticles on physical and mechanical properties of cement at low temperatures. Adv Mater Sci Eng. https://doi.org/10.1155/2018/8934689

Senff L, Hotza D, Lucas S, Ferreira VM, Labrincha JA (2012) Effect of nano-SiO2 and nano-TiO2 addition on the rheological behavior and the hardened properties of cement mortars. Mater Sci Eng A 532:354–361. https://doi.org/10.1016/j.msea.2011.10.102

Ma B, Li H, Mei J, Li X, Chen F (2015) Effects of nano-TiO2 on the toughness and durability of cement-based material. Adv Mater Sci Eng. https://doi.org/10.1155/2015/583106

Zhang R, Cheng X, Hou P, Ye Z (2015) Influences of nano-TiO2 on the properties of cement-based materials: hydration and drying shrinkage. Constr Build Mater 81:35–41. https://doi.org/10.1016/j.conbuildmat.2015.02.003

Lee BY, Kurtis KE (2012) Proposed acceleratory effect of TiO2 nanoparticles on belite hydration: preliminary results. J Am Ceram Soc 95(1):365–368. https://doi.org/10.1111/j.1551-2916.2011.04937.x

Jayapalan AR, Lee BY, Fredrich SM, Kurtis KE (2010) Influence of additions of anatase TiO2 nanoparticles on early-age properties of cement-based materials. Transp Res Rec 2141(1):41–46. https://doi.org/10.3141/2141-08

Nazari A, Riahi S (2010) The effect of TiO2 nanoparticles on water permeability and thermal and mechanical properties of high strength self-compacting concrete. Mater Sci Eng A 528(2):756–763. https://doi.org/10.1016/j.msea.2010.09.074

Meng T, Yu Y, Qian X, Zhan S, Qian K (2012) Effect of nano-TiO2 on the mechanical properties of cement mortar. Constr Build Mater 29:241–245. https://doi.org/10.1016/j.conbuildmat.2011.10.047

Akono AT, Ulm FJ (2014) An improved technique for characterizing the fracture toughness via scratch test experiments. Wear 313:117–124. https://doi.org/10.1016/j.wear.2014.02.015

Akono AT, Randall NX, Ulm FJ (2012) Experimental determination of the fracture toughness via micro scratch tests: application to polymers, ceramics and metals. J Mat Res 27:485–493. https://doi.org/10.1557/jmr.2011.402

Oliver WC, Pharr GM (2004) Measurement of hardness and elastic modulus by instrumented indentation: advances in understanding and refinements to methodology. J Mat Res 19(1):3–20. https://doi.org/10.1557/jmr.2004.19.1.3

Oliver WC, Pharr GM (1992) An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J Mat Res 7(6):1564–1583. https://doi.org/10.1557/JMR.1992.1564

Vandamme M (2008) The nanogranular origin of concrete creep: a nanoindentation investigation of microstructure and fundamental properties of calcium-silicate-hydrates. PhD dissertation, Massachusetts Institute of Technology.

Vandamme M, Ulm FJ (2013) Nanoindentation investigation of creep properties of calcium silicate hydrates. Cem Concr Res 52:38–52. https://doi.org/10.1016/j.cemconres.2013.05.006

Sorelli L, Constantinides G, Ulm FJ, Toutlemonde F (2008) The nano-mechanical signature of ultra high performance concrete by statistical nanoindentation techniques. Cem Concr Res 38(12):1447–1456. https://doi.org/10.1016/j.cemconres.2008.09.002

Cotterell B, Mai YW (1987) Crack growth resistance curve and size effect in the fracture of cement paste. J Mat Sci 22(8):2734–2738

Hu X, Wittmann F (2000) Size effect on toughness induced by crack close to free surface. Eng Fract Mech 65(2-3):209–221. https://doi.org/10.1016/S0013-7944(99)00123-X

Pellenq RJM, Van Damme H (2004) Why does concrete set?: The nature of cohesion forces in hardened cement-based materials. MRS Bull 29(5):319–323. https://doi.org/10.1557/mrs2004.97

Shahsavari R, Buehler MJ, Pellenq RJM, Ulm FJ (2009) First-principles study of elastic constants and interlayer interactions of complex hydrated oxides: case study of tobermorite and jennite. J Am Cer Soc 92(10):2323–2330. https://doi.org/10.1111/j.1551-2916.2009.03199.x

Jennings HM (2000) A model for the microstructure of calcium silicate hydrate in cement paste. Cem Concr Res 30(1):101–116. https://doi.org/10.1016/S0008-8846(99)00209-4

Jennings HM (2004) Colloid model of C− S− H and implications to the problem of creep and shrinkage. Mater Struct 37(1):59–70

Jennings HM (2008) Refinements to colloid model of CSH in cement: CM-II. Cem Concr Res 38(3):275–289. https://doi.org/10.1016/j.cemconres.2007.10.006

Tennis PD, Jennings H (2000) A model for two types of calcium silicate hydrate in the microstructure of Portland cement pastes. Cem Concr Res 30(6):855–863. https://doi.org/10.1016/S0008-8846(00)00257-X

Constantinides G, Ulm FJ (2007) The nanogranular nature of C–S–H. J Mech Phys Sol 55(1):64–90. https://doi.org/10.1016/j.jmps.2006.06.003

Thomas JJ, Jennings HM (2006) A colloidal interpretation of chemical aging of the CSH gel and its effects on the properties of cement paste. Cem Concr Res 36(1):30–38. https://doi.org/10.1016/j.cemconres.2004.10.022

Vandamme M, Ulm FJ (2009) Nanogranular origin of concrete creep. Proc Natl Acad Sci 106(26):10552–10557. https://doi.org/10.1073/pnas.0901033106

Acknowledgements

This work was supported by the National Science Foundation under Grant No. CMMI 1829101. This work made use of the EPIC facility of Northwestern University’s NUANCE Center, which has received support from the Soft and Hybrid Nanotechnology Experimental (SHyNE) Resource (NSF ECCS-1542205); the MRSEC program (NSF DMR-1720139) at the Materials Research Center; the International Institute for Nanotechnology (IIN); the Keck Foundation; and the State of Illinois, through the IIN. A special thanks to Jiaxin Chen for conducting the FTIR tests.

Funding

This study was funded by the National Science Foundation under Grant No. CMMI 1829101.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author declares that she has no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Akono, AT. Effect of nano-TiO2 on C–S–H phase distribution within Portland cement paste. J Mater Sci 55, 11106–11119 (2020). https://doi.org/10.1007/s10853-020-04847-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04847-5