Abstract

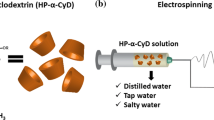

Hydrophobic cyclodextrin (CD) nanofibers were produced by the electrospinning of peracetylated β-CD without requiring any polymer as a carrier matrix. Native β-CD was peracetylated through the reaction with acetic anhydride, and the conversion of all hydroxyl groups into acetyl was confirmed by NMR, XPS, and TGA analyses. The peracetyl modification drastically boosted the thermal stability of the β-CD molecules. The electrospinning of the peracetylated β-CD from its highly concentrated solutions (180% (w/v)) in DMF led to bead-free nanofibers, while electrospinning at the concentrations of 140 and 160% (w/v) CDs resulted in beads and beaded nanofibers, respectively. The electrospinning process parameters such as applied voltage, flow rate, and tip-to-collector distances were systematically altered to produce a uniform nanofiber structure. The flow rate had the most drastic effect on the diameter and morphology of the resultant nanofibers: A threefold rise in the fiber diameter was observed with increasing the flow rate from 0.1 to 2 mL h−1. Similarly, higher electrical field increased the fiber diameter due to higher mass flow, while boosting the tip-to-collector distance did not reveal any significant change on the fiber diameter. The stability of the peracetylated β-CD nanofibers was observed in water for 24 h without any significant morphological change; however, the dissolution of the nanofiber mat was observed with a long-time exposure to water. We demonstrated production of hydrophobic uniform CD nanofibers without using any carrier polymer.

Similar content being viewed by others

References

Biwer A, Antranikian G, Heinzle E (2002) Enzymatic production of cyclodextrins. Appl Microbiol Biotechnol 59:609. https://doi.org/10.1007/s00253-002-1057-x

Tabushi I (1982) Cyclodextrin catalysis as a model for enzyme action. Acc Chem Res 15:66. https://doi.org/10.1021/ar00075a001

Brewster ME, Hora MS, Simpkins JW, Bodor N (1991) Use of 2-hydroxypropyl-β-cyclodextrin as a solubilizing and stabilizing excipient for protein drugs. Pharm Res 8:792. https://doi.org/10.1023/A:1015870521744

Brewster ME, Loftsson T (2007) Cyclodextrins as pharmaceutical solubilizers. Adv Drug Deliv Rev 59:645. https://doi.org/10.1016/j.addr.2007.05.012

Wang X, Brusseau ML (1993) Solubilization of some low-polarity organic compounds by hydroxypropyl-beta-cyclodextrin. Environ Sci Technol 27:2821. https://doi.org/10.1021/es00049a023

Buschmann HJ, Denter U, Knittel D, Schollmeyer E (1998) The use of cyclodextrins in textile processes: an overview. J Text Inst 89:554. https://doi.org/10.1080/00405009808658641

Thatiparti TR, Shoffstall AJ, von Recum HA (2010) Cyclodextrin-based device coatings for affinity-based release of antibiotics. Biomaterials 31:2335. https://doi.org/10.1016/j.biomaterials.2009.11.087

Celebioglu A, Topuz F, Uyar T (2019) Water-insoluble hydrophilic electrospun fibrous mat of cyclodextrin-epichlorohydrin polymer as highly effective sorbent. ACS Appl Polym Mater. https://doi.org/10.1021/acsapm.8b00034

Mellet CO, Fernández JMG, Benito JM (2011) Cyclodextrin-based gene delivery systems. Chem Soc Rev 40:1586. https://doi.org/10.1039/C0CS00019A

Topuz F, Uyar T (2019) Electrospinning of cyclodextrin functional nanofibers for drug delivery applications. Pharmaceutics 11:6. https://doi.org/10.3390/pharmaceutics11010006

Lee Jung B, Kim JE, Balikov DA et al (2016) Poly(l-lactic acid)/gelatin fibrous scaffold loaded with simvastatin/beta-cyclodextrin-modified hydroxyapatite inclusion complex for bone tissue regeneration. Macromol Biosci 16:1027. https://doi.org/10.1002/mabi.201500450

Singh N, Sahu O (2019) In: Shahid ul I, Butola BS (eds) The impact and prospects of green chemistry for textile technology. Woodhead Publishing

Fenyvesi É, Vikmon M, Szente L (2016) Cyclodextrins in food technology and human nutrition: benefits and limitations. Crit Rev Food Sci Nutr 56:1981. https://doi.org/10.1080/10408398.2013.809513

Ahn Y, Kang Y, Ku M, Yang Y-H, Jung S, Kim H (2013) Preparation of β-cyclodextrin fiber using electrospinning. RSC Adv 3:14983. https://doi.org/10.1039/C3RA42339E

Celebioglu A, Uyar T (2012) Electrospinning of nanofibers from non-polymeric systems: polymer-free nanofibers from cyclodextrin derivatives. Nanoscale 4:621. https://doi.org/10.1039/C1NR11364J

Celebioglu A, Uyar T (2020) Electrospinning of cyclodextrins: hydroxypropyl-alpha-cyclodextrin nanofibers. J Mater Sci 55:404. https://doi.org/10.1007/s10853-019-03983-x

Manasco JL, Saquing CD, Tang C, Khan SA (2012) Cyclodextrin fibers via polymer-free electrospinning. RSC Adv 2:3778. https://doi.org/10.1039/C2RA00004K

Topuz F, Uyar T (2018) Influence of hydrogen-bonding additives on electrospinning of cyclodextrin nanofibers. ACS Omega 3:18311. https://doi.org/10.1021/acsomega.8b02662

Celebioglu A, Yildiz ZI, Uyar T (2017) Electrospun crosslinked poly-cyclodextrin nanofibers: highly efficient molecular filtration thru host-guest inclusion complexation. Sci Rep 7:7369. https://doi.org/10.1038/s41598-017-07547-4

Celebioglu A, Topuz F, Yildiz ZI, Uyar T (2019) Efficient removal of polycyclic aromatic hydrocarbons and heavy metals from water by electrospun nanofibrous polycyclodextrin membranes. ACS Omega 4:7850. https://doi.org/10.1021/acsomega.9b00279

Boger J, Corcoran RJ, Lehn J-M (1978) Cyclodextrin chemistry: selective modification of all primary hydroxyl groups of α- and β-cyclodextrins. Helv Chim Acta 61:2190. https://doi.org/10.1002/hlca.19780610622

Yu HS, Lee JM, Youn YS, Oh KT, Na K, Lee ES (2018) γ-Cyclodextrin-phenylacetic acid mesh as a drug trap. Carbohydr Polym 184:390. https://doi.org/10.1016/j.carbpol.2017.12.078

Lei L, Buddingh J, Wang J, Liu G (2020) Transparent omniphobic polyurethane coatings containing partially acetylated β–cyclodextrin as the polyol. Chem Eng J 380:122554. https://doi.org/10.1016/j.cej.2019.122554

Liu Z-T, Shen L-H, Liu Z-W, Lu J (2009) Acetylation of β-cyclodextrin in ionic liquid green solvent. J Mater Sci 44:1813. https://doi.org/10.1007/s10853-008-3238-1

Xiao Y, Lim HM, Chung TS, Rajagopalan R (2007) Acetylation of β-cyclodextrin surface-functionalized cellulose dialysis membranes with enhanced chiral separation. Langmuir 23:12990. https://doi.org/10.1021/la7026384

Sultana T, Jung JM, Hong S-S et al (2012) Characteristic profiles of the inclusion complex of omeprazole/peracylated-β-cyclodextrin formed in supercritical carbon dioxide. J Incl Phenom Macro 72:207. https://doi.org/10.1007/s10847-011-9966-x

Topuz F, Satilmis B, Uyar T (2019) Electrospinning of uniform nanofibers of polymers of intrinsic microporosity (PIM-1): the influence of solution conductivity and relative humidity. Polymer 178:121610. https://doi.org/10.1016/j.polymer.2019.121610

Topuz F, Uyar T (2017) Electrospinning of gelatin with tunable fiber morphology from round to flat/ribbon. Mater Sci Eng C 80:371. https://doi.org/10.1016/j.msec.2017.06.001

Demir MM, Yilgor I, Yilgor E, Erman B (2002) Electrospinning of polyurethane fibers. Polymer 43:3303. https://doi.org/10.1016/S0032-3861(02)00136-2

Li L, Hsieh Y-L (2005) Ultra-fine polyelectrolyte fibers from electrospinning of poly(acrylic acid). Polymer 46:5133. https://doi.org/10.1016/j.polymer.2005.04.039

Heikkilä P, Harlin A (2008) Parameter study of electrospinning of polyamide-6. Eur Polym J 44:3067. https://doi.org/10.1016/j.eurpolymj.2008.06.032

Yang Y, Jia Z, Li Q, Guan Z (2006) Experimental investigation of the governing parameters in the electrospinning of polyethylene oxide solution. IEEE Trans Dielectr Electr Insul 13:580. https://doi.org/10.1109/TDEI.2006.1657971

Wang C (2006) Effect of concentration, voltage, take-over distance and diameter of pinhead on precursory poly (phenylene vinylene) electrospinning. Pigm Resin Technol 35:278. https://doi.org/10.1108/03699420610692887

Li Z, Wang C (2013) In: Li Z, Wang C (eds) One-dimensional nanostructures: electrospinning technique and unique nanofibers. Springer, Berlin

Kidoaki S, Kwon IK, Matsuda T (2006) Structural features and mechanical properties of in situ–bonded meshes of segmented polyurethane electrospun from mixed solvents. J Biomed Mater Res B. https://doi.org/10.1002/jbm.b.30336

Wang C, Hsu C-H, Lin J-H (2006) Scaling laws in electrospinning of polystyrene solutions. Macromolecules 39:7662. https://doi.org/10.1021/ma060866a

Zong X, Kim K, Fang D, Ran S, Hsiao BS, Chu B (2002) Structure and process relationship of electrospun bioabsorbable nanofiber membranes. Polymer 43:4403. https://doi.org/10.1016/S0032-3861(02)00275-6

Zeng J, Chen X, Xu X et al (2003) Ultrafine fibers electrospun from biodegradable polymers. J Appl Polym 89:1085. https://doi.org/10.1002/app.12260

Haghi AK, Akbari M (2007) Trends in electrospinning of natural nanofibers. Phys Status Solidi A 204:1830. https://doi.org/10.1002/pssa.200675301

Megelski S, Stephens JS, Bruce CD, Rabolt JF (2002) Micro- and nanostructured surface morphology on electrospun polymer fibers. Macromolecules 35:8456. https://doi.org/10.1021/ma020444a

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors have no other conflicts of interest to declare.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Topuz, F., Shaikh, A.Y., Guler, M.O. et al. Water-insoluble polymer-free uniform nanofibers of peracetylated cyclodextrin by electrospinning. J Mater Sci 55, 11752–11762 (2020). https://doi.org/10.1007/s10853-020-04820-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04820-2