Abstract

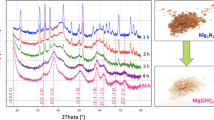

Patterned Mg2Si structures can be attractive for use in optoelectronic, thermoelectric, and other devices. Such structures can be fabricated as conformal Mg2Si films on patterned Si substrates via direct reaction of these substrates with Mg vapor at modest temperatures and ambient pressure. Here, we report the kinetic mechanism (rate-limiting step and associated rate law) that controls such vapor/solid reactive formation of conformal Mg2Si films. To avoid oxidation during silicide formation, experiments were conducted within metal ampoules that were sealed in an argon atmosphere. Upon heating each sealed ampoule to 600 °C, Mg vapor (generated from solid Mg sealed within the ampoule) underwent reaction with a Si single-crystal plate (located a fixed distance from the solid Mg within the ampoule). Kinetic data were obtained by evaluating the change in thickness of the product Mg2Si film, and the specimen mass change per area, with reaction time at 600 °C. The changes in mass and in film thickness were both found to follow parabolic kinetics, with the rate constants obtained from both types of measurements in good agreement. Changes in the diffusion distance of the Mg vapor to the reacting Si single-crystal plate, and in the crystal orientation of the plate, were found to have negligible influences on the reaction kinetics. Such data were consistent with solid-state diffusion through the Mg2Si product layer as the rate-limiting step. An inert marker experiment was used to determine the predominant interface at which Mg2Si formed, and to evaluate the rate-limiting species controlling such formation.

Similar content being viewed by others

References

Kato T, Sago Y, Fujiwara H (2011) Optoelectronic properties of Mg2Si semiconducting layers with high absorption coefficients. J Appl Phys 110(6):063723

Chernev IM, Shevlyagin AV, Galkin KN, Stuchlik J, Remes Z, Fajgar R, Galkin NG (2016) On the way to enhance the optical absorption of a-Si in NIR by embedding Mg2Si thin film. Appl Phys Lett 109:043902

Deng Q, Wang Z, Wang S, Shao G (2017) Simulation of planar Si/Mg2Si/Si p-i-n heterojunction solar cells for high efficiency. Sol Energy 158:654–662

Udono H, Tajima H, Uchikoshi M, Itakura M (2015) Crystal growth and characterization of Mg2Si for IR-detectors and thermoelectric applications. Jpn J Appl Phys 54:07JB06

Sakamoto T, Iida T, Kurosaki S, Yano K, Taguchi H, Nishio K, Takanashi Y (2011) Thermoelectric behavior of Sb- and Al-doped n-type Mg2Si device under large temperature differences. J Electron Mater 40:629–634

Chen ZJ, Zhou BY, Li JX, Wen CL (2016) Thermoelectric properties of Al-doped Mg2Si thin films deposited by magnetron sputtering. Appl Surf Sci 386:389–392

Fedorov MI, Isachenko GN (2015) Silicides: materials for thermoelectric energy conversion. Jpn J Appl Phys 54:07JA05

Schmidt RD, Case ED, Giles J, Ni JE, Hogan TP (2012) Room-temperature mechanical properties and slow crack growth behavior of Mg2Si thermoelectric materials. J Electron Mater 41:1210–1216

Zhao Y, Dou SX, Ionescu M, Munroe P (2006) Significant improvement of activation energy in MgB2/Mg2Si multilayer films. Appl Phys Lett 88:012502

Yamaguchi T, Serikawa T, Henmi M, Oginuma H, Kondoh K (2006) Mg2Si coating technology on magnesium alloys to improve corrosion and wear resistance. Mater Trans 47:1026–1030

Kogut I, Record MC (2012) Magnesium silicide thin film formation by reactive diffusion. Thin Solid Films 522:149–158

Battiston S, Boldrini S, Fiameni S, Famengo A, Fabrizio M, Barison S (2012) Multilayered thin films for oxidation protection of Mg2Si thermoelectric material at middle-high temperatures. Thin Solid Films 526:150–154

Goranova E, Amov B, Baleva M, Trifonova EP, Yordanov P (2004) Ion beam synthesis of Mg2Si. J Mater Sci 39:1857–1859. https://doi.org/10.1023/B:JMSC.0000016203.26451.4c

Serikawa T, Henmi M, Kondoh K (2004) Microstructure and Mg concentration of Mg–Si thin film deposited by ion beam sputtering on glass substrate. J Vac Sci Technol A Vac Surf Films 22:1971–1974

Larruquert JI, Keski-Kuha RAM (2000) Reflectance measurements and optical constants in the extreme ultraviolet for thin films of ion-beam-deposited SiC, Mo, Mg2Si, and InSb and of evaporated Cr. Appl Opt 39:2772–2781

Wittmer M, Lüthy W, Von Allmen M (1979) Laser induced reaction of magnesium with silicon. Phys Lett A 75:127–130

Song S-W, Striebel KA, Reade RP, Roberts GA, Cairns EJ (2003) Electrochemical studies of nanoncrystalline Mg2Si thin film electrodes prepared by pulsed laser deposition. J Electrochem Soc 150:A121–A127

Mahan JE, Vantomme A, Langouche G, Becker JP (1996) Semiconducting Mg2Si thin films prepared by molecular-beam epitaxy. Phys Rev B 54:16965–16971

Gordin AS, Sandhage KH (2018) In situ high-temperature X-ray diffraction analysis of Mg2Si formation kinetics via reaction of Mg films with Si single crystal substrates. Intermetallics 94:200–209

Chu WK, Lau SS, Mayer JW, Müller H, Tu KN (1975) Implanted noble gas atoms as diffusion markers in silicide formation. Thin Solid Films 25:393–402

Lee HJ, Cho YR, Kim IH (2011) Synthesis of thermoelectric Mg2Si by a solid state reaction. J Ceram Process Res 12:16–20

Matsui H, Kuramoto M, Ono T, Nose Y, Tatsuoka H, Kuwabara H (2002) Growth of Ca2Si layers on Mg2Si/Si(111) substrates. J Crystal Growth 237–239:2121–2124

Hosono T, Matsuzawa Y, Kuramoto M, Momose Y, Tatsuoka H, Kuwabara H (2003) Simple fabrication of Mg2Si thermoelectric generator. Solid State Phenom 93:447–452

Hu J, Sato Y, Hosono T, Tatsuoka H (2009) Growth condition dependence of structural and electrical properties of Mg2Si layers grown on silicon substrates. Vacuum 83:1494–1497

Okamoto H (2007) Mg–Si (magnesium–silicon). J Phase Equilibria Diffus 28:229–230

Wang X-N, Wang Y, Zou J, Zhang T-C, Mei Z-X, Guo Y, Xue Q-K, Du X-I, Zhang X-N, Han X-D, Zhang Z (2009) Thermal stability of Mg2Si epitaaxial film formed on Si(111) substrate by solid phase reaction. Chin Phys B 18:3079–3083

Xiao Q, Fang D, Liu X, Liao Y, Zhao K, Xie Q (2017) Heat treatment temperature effects on the formation of Mg2Si films deposited by electron beam evaporation. J Mater Sci Mater Electron 28:702–706

Vantomme A, Mahan JE, Langouche G, Becker JP, Van Bael M, Ternst K, Van Haesendonck C (1997) Thin film growth of semiconducting Mg2Si by co-deposition. Appl Phys Lett 70:1086–1088

Vantomme A, Langouche G, Mahan JE, Becker JP (2000) Growth mechanism and optical properties of semiconducting Mg2Si thin films. Microelectron Eng 50:237–242

Joint Committee on Powder Diffraction Standards (JCPDS) International Center for Diffraction Data (2007) File 00–035–0773 for Mg2Si. http://www.icdd.com/index.php/pdf-4 (JCPDS International Center for Diffraction Data, Newtown Square)

Barin I (1997) Thermochemical data of pure substances. Wiley-VCH Verlag GmbH, Weinheim

Gourishankar KV, Karaminezhad Ranjbar M, St. Pierre GR (1993) Revision of the enthalpies and Gibbs energies of formation of calcium oxide and magnesium oxide. J Phase Equilibria 14:601–611

Alves H, Koster U, Aghion E, Eliezer D (2001) Environmental behavior of magnesium and magnesium alloys. Mater Technol Adv Perform Mater 16:110–141

Sh Mikhail R, Gouda VK (1960) Rate of oxidation of magnesium metal in dry oxygen. J Appl Chem 10:384–388

Leontis TE, Rhines FN (1946) Rates of high-temperature oxidation of magnesium and magnesium alloys. Trans AIME 166:265–294

Murray JL (1986) The magnesium-titanium system. Bull Alloy Phase Diagr 7:245–248

Nayeb-Hashemi AA, Clark JB, Swartzendruber LJ (1985) The Fe–Mg (iron–magnesium) system. Bull Alloy Phase Diagr 6:235–238

Haitani T, Tamura Y, Motegi T, Kono N, Tamehiro H (2003) Solubility of iron in pure magnesium and cast structure of Mg–Fe alloy. Mater Sci Forum 419–422:697–702

Okamoto H (2000) Cr–Mg (chromium–magnesium). J Phase Equilibria 21:209

Acknowledgements

This work was supported by the U.S. Department of Energy, Office of Science, Basic Energy Sciences, under Award # DE-SC0014034.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest associated with the studies mentioned in the present research article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, J., Hwang, S., Itskos, G. et al. Kinetic mechanism of conformal magnesium silicide (Mg2Si) film formation via reaction of Si single crystals with Mg vapor. J Mater Sci 55, 1107–1116 (2020). https://doi.org/10.1007/s10853-019-04083-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-04083-6