Abstract

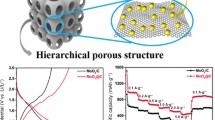

In this work, the microwave-assisted synthesis of manganese metal–organic framework (MOF) material is presented. Synthesis procedure is based on a microwave-assisted solvothermal reaction of manganese(III) acetylacetonate with biphenyl-4,4′-dicarboxylic acid (Bpdc) in N,N′-dimethylformamide at the temperature of 160 °C. The obtained Mn-based metal–organic framework, labeled as Mn-Bpdc, was used as a precursor for the preparation of a porous MnO/carbon nanocomposite, which was obtained via thermal transformation in a nitrogen atmosphere at 700 °C. It was found that this approach provides an effective and simple preparation pathway for porous carbon decorated with homogeneously embedded manganese(II) oxide nanoparticles. Both Mn-Bpdc and MnO/C nanocomposite materials were characterized by a variety of physicochemical methods. The prepared MnO/C nanocomposite material was deposited on a cathode surface of lithium-sulfur batteries and utilized as a shuttle suppressing layer. This electrode structure immobilizes polysulfides inside the cathode and improves the stability during cycling. The electrode with MnO/C nanocomposite shuttle suppressing layer maintains high stability during cycling in comparison with a standard electrode. The electrode with MnO/C composite layer exhibits 84.8% capacity retention after 50 cycles at different C-rates compared to 76.2% obtained for the standard electrode.

Similar content being viewed by others

References

Manthiram A, Fu Y, Chung SH et al (2014) Rechargeable lithium–sulfur batteries. Chem Rev 114:11751–11787. https://doi.org/10.1021/cr500062v

Li T, Bai X, Gulzar U et al (2019) A comprehensive understanding of lithium–sulfur battery technology. Adv Funct Mater. https://doi.org/10.1002/adfm.201901730

Nitta N, Wu F, Lee JT, Yushin G (2015) Li–ion battery materials: present and future. Mater Today 18:252–264. https://doi.org/10.1016/j.mattod.2014.10.040

Kim J, Lee D-J, Jung H-G et al (2013) An advanced lithium–sulfur battery. Adv Funct Mater 23:1076–1080. https://doi.org/10.1002/adfm.201200689

Wang Y, Huang X, Zhang S, Hou Y (2018) Sulfur hosts against the shuttle effect. Small Methods 2:1700345. https://doi.org/10.1002/smtd.201700345

Liu Z, Liu B, Guo P et al (2018) Enhanced electrochemical kinetics in lithium–sulfur batteries by using carbon nanofibers/manganese dioxide composite as a bifunctional coating on sulfur cathode. Electrochim Acta 269:180–187. https://doi.org/10.1016/j.electacta.2018.02.160

Fan X, Sun W, Meng F et al (2018) Advanced chemical strategies for lithium–sulfur batteries: a review. Green Energy Environ 3:2–19. https://doi.org/10.1016/j.gee.2017.08.002

Juhl AC, Schneider A, Ufer B et al (2016) Mesoporous hollow carbon spheres for lithium–sulfur batteries: distribution of sulfur and electrochemical performance. Beilstein J Nanotechnol 7:1229–1240. https://doi.org/10.3762/bjnano.7.114

Liu Q, Zhu J, Zhang L, Qiu Y (2018) Recent advances in energy materials by electrospinning. Renew Sustain Energy Rev 81:1825–1858. https://doi.org/10.1016/j.rser.2017.05.281

Wu F, Zhao S, Chen L et al (2018) Metal–organic frameworks composites threaded on the CNT knitted separator for suppressing the shuttle effect of Lithium sulfur batteries. Energy Storage Mater 14:383–391. https://doi.org/10.1016/j.ensm.2018.06.009

Hu N, Lv X, Dai Y et al (2018) SnO2/reduced graphene oxide interlayer mitigating the shuttle effect of Li–S batteries. ACS Appl Mater Interfaces 10:18665–18674. https://doi.org/10.1021/acsami.8b03255

Tan L, Li X, Wang Z et al (2018) Lightweight reduced graphene Oxide@MoS 2 interlayer as polysulfide barrier for high-performance lithium–sulfur batteries. ACS Appl Mater Interfaces 10:3707–3713. https://doi.org/10.1021/acsami.7b18645

Lin Y, Pitcheri R, Zhu J et al (2019) Electrospun PVDF/PSSLi ionomer films as a functional separator for lithium-sulfur batteries. J Alloys Compd 785:627–633. https://doi.org/10.1016/j.jallcom.2019.01.202

Yao H, Yan K, Li W et al (2014) Improved lithium–sulfur batteries with a conductive coating on the separator to prevent the accumulation of inactive S-related species at the cathode–separator interface. Energy Environ Sci 7:3381–3390. https://doi.org/10.1039/C4EE01377H

Kwok CY, Pang Q, Worku AF et al (2019) Impact of the mechanical properties of a functionalized cross-linked binder on the longevity of Li–S batteries. ACS Appl Mater Interfaces 11:22481–22491. https://doi.org/10.1021/acsami.9b06456

Kim PJ, Fontecha HD, Kim K, Pol VG (2018) Toward high-performance lithium–sulfur batteries: upcycling of LDPE plastic into sulfonated carbon scaffold via microwave-promoted sulfonation. ACS Appl Mater Interfaces 10:14827–14834. https://doi.org/10.1021/acsami.8b03959

Liu X, Huang J-Q, Zhang Q, Mai L (2017) Nanostructured metal oxides and sulfides for lithium–sulfur batteries. Adv Mater 29:1601759. https://doi.org/10.1002/adma.201601759

Liu Y, Han D, Wang L et al (2019) NiCo2O4 nanofibers as carbon-free sulfur immobilizer to fabricate sulfur-based composite with high volumetric capacity for lithium–sulfur battery. Adv Energy Mater 9:1803477. https://doi.org/10.1002/aenm.201803477

Liu X-F, Guo X-Q, Wang R et al (2019) Manganese cluster-based MOF as efficient polysulfide-trapping platform for high-performance lithium–sulfur batteries. J Mater Chem A 7:2838–2844. https://doi.org/10.1039/C8TA09973A

Zheng Y, Zheng S, Xue H, Pang H (2019) Metal–organic frameworks for lithium–sulfur batteries. J Mater Chem A 7:3469–3491. https://doi.org/10.1039/C8TA11075A

Wu DS, Shi F, Zhou G et al (2018) Quantitative investigation of polysulfide adsorption capability of candidate materials for Li–S batteries. Energy Storage Mater 13:241–246. https://doi.org/10.1016/j.ensm.2018.01.020

Hart CJ, Cuisinier M, Liang X et al (2015) Rational design of sulphur host materials for Li–S batteries: correlating lithium polysulphide adsorptivity and self-discharge capacity loss. Chem Commun 51:2308–2311. https://doi.org/10.1039/c4cc08980d

Liang X, Hart C, Pang Q et al (2015) A highly efficient polysulfide mediator for lithium–sulfur batteries. Nat Commun 6:1–8. https://doi.org/10.1038/ncomms6682

Liu Y, Feng G, Guo X et al (2018) Employing MnO as multifunctional polysulfide reservoirs for enhanced-performance Li–S batteries. J Alloys Compd 748:100–110. https://doi.org/10.1016/j.jallcom.2018.03.110

Pang Q, Liang X, Kwok CY, Nazar LF (2015) Review—the importance of chemical interactions between sulfur host materials and lithium polysulfides for advanced lithium–sulfur batteries. J Electrochem Soc 162:A2567–A2576. https://doi.org/10.1149/2.0171514jes

An T, Deng D, Lei M et al (2016) MnO modified carbon nanotubes as a sulfur host with enhanced performance in Li/S batteries. J Mater Chem A 4:12858–12864. https://doi.org/10.1039/C6TA04445J

Qian X, Jin L, Zhao D et al (2016) Ketjen black-MnO composite coated separator for high performance rechargeable lithium–sulfur battery. Electrochim Acta 192:346–356. https://doi.org/10.1016/j.electacta.2016.01.225

Zhu J, Pitcheri R, Kang T et al (2018) Electrospun carbon nanofibers decorated with MnO nanoparticles as a sulfur-absorbent for lithium–sulfur batteries. Ceram Int 44:16837–16843. https://doi.org/10.1016/j.ceramint.2018.06.119

Lin C, Qu L, Li J et al (2019) Porous nitrogen-doped carbon/MnO coaxial nanotubes as an efficient sulfur host for lithium sulfur batteries. Nano Res 12:205–210. https://doi.org/10.1007/s12274-018-2203-9

Kuroda S, Tobori N, Sakuraba M, Sato Y (2003) Charge–discharge properties of a cathode prepared with ketjen black as the electro-conductive additive in lithium ion batteries. J Power Sources 119–121:924–928. https://doi.org/10.1016/S0378-7753(03)00230-1

Sun K, Cama CA, Huang J et al (2017) Effect of carbon and binder on high sulfur loading electrode for Li–S battery technology. Electrochim Acta 235:399–408. https://doi.org/10.1016/j.electacta.2017.03.023

Hu L, Chen Q (2014) Hollow/porous nanostructures derived from nanoscale metal–organic frameworks towards high performance anodes for lithium–ion batteries. Nanoscale 6:1236–1257. https://doi.org/10.1039/C3NR05192G

Zheng F, Xia G, Yang Y, Chen Q (2015) MOF-derived ultrafine MnO nanocrystals embedded in a porous carbon matrix as high-performance anodes for lithium–ion batteries. Nanoscale 7:9637–9645. https://doi.org/10.1039/C5NR00528K

Chen LD, Zheng YQ, Zhu HL (2018) Manganese oxides derived from Mn(II)-based metal–organic framework as supercapacitor electrode materials. J Mater Sci 53:1346–1355. https://doi.org/10.1007/s10853-017-1575-7

Wang YC, Li WB, Zhao L, Xu BQ (2016) MOF-derived binary mixed metal/metal oxide @carbon nanoporous materials and their novel supercapacitive performances. Phys Chem Chem Phys 18:17941–17948. https://doi.org/10.1039/C6CP02374F

Yang W, Li X, Li Y et al (2018) Applications of metal–organic-framework-derived carbon materials. Adv Mater 31:1804740. https://doi.org/10.1002/adma.201804740

Furukawa H, Cordova KE, O’Keeffe M, Yaghi OM (2013) The chemistry and applications of metal–organic frameworks. Science 341:1230444. https://doi.org/10.1126/science.1230444

Rowsell JLC, Yaghi OM (2004) Metal–organic frameworks: a new class of porous materials. Microporous Mesoporous Mater 73:3–14. https://doi.org/10.1016/j.micromeso.2004.03.034

Zhong R-Q, Zou R-Q, Du M et al (2010) Metal–organic frameworks of manganese(II) 4,4′-biphenyldicarboxylates: crystal structures, hydrogen adsorption, and magnetism properties. CrystEngComm 12:677–681. https://doi.org/10.1039/B916168F

Liu J, Wöll C (2017) Surface-supported metal–organic framework thin films: fabrication methods, applications, and challenges. Chem Soc Rev 46:5730–5770. https://doi.org/10.1039/C7CS00315C

Flage-Larsen E, Thorshaug K (2014) Linker conformation effects on the band gap in metal-organic frameworks. Inorg Chem 53:2569–2572. https://doi.org/10.1021/ic4028628

Lu W, Wei Z, Gu Z-Y et al (2014) Tuning the structure and function of metal–organic frameworks via linker design. Chem Soc Rev 43:5561–5593. https://doi.org/10.1039/C4CS00003J

Millward AR, Yaghi OM (2005) Metal–organic frameworks with exceptionally high capacity for storage of carbon dioxide at room temperature. J Am Chem Soc 127:17998–17999. https://doi.org/10.1021/ja0570032

Li J-R, Kuppler RJ, Zhou H-C (2009) Selective gas adsorption and separation in metal–organic frameworks. Chem Soc Rev 38:1477–1504. https://doi.org/10.1039/b802426j

Wang L, Han Y, Feng X et al (2016) Metal–organic frameworks for energy storage: batteries and supercapacitors. Coord Chem Rev 307:361–381. https://doi.org/10.1016/j.ccr.2015.09.002

Zhu L, Liu X-Q, Jiang H-L, Sun L-B (2017) Metal–organic frameworks for heterogeneous basic catalysis. Chem Rev 117:8129–8176. https://doi.org/10.1021/acs.chemrev.7b00091

Butler KT, Hendon CH, Walsh A (2014) Electronic structure modulation of metal–organic frameworks for hybrid devices. ACS Appl Mater Interfaces 6:22044–22050. https://doi.org/10.1021/am507016r

Kreno LE, Leong K, Farha OK et al (2012) Metal–organic framework materials as chemical sensors. Chem Rev 112:1105–1125. https://doi.org/10.1021/cr200324t

Horcajada P, Gref R, Baati T et al (2012) Metal–organic frameworks in biomedicine. Chem Rev 112:1232–1268. https://doi.org/10.1021/cr200256v

Kazda T, Čudek P, Vondrák J et al (2018) Lithium–sulphur batteries based on biological 3D structures. J Solid State Electrochem 22:537–546. https://doi.org/10.1007/s10008-017-3791-0

Jacquemin M, Genet MJ, Gaigneaux EM, Debecker DP (2013) Calibration of the X-ray photoelectron spectroscopy binding energy scale for the characterization of heterogeneous catalysts: Is everything really under control? ChemPhysChem 14:3618–3626. https://doi.org/10.1002/cphc.201300411

Shirley DA (1972) High-resolution X-ray photoemission spectrum of the valence bands of gold. Phys Rev B 5:4709–4714. https://doi.org/10.1103/PhysRevB.5.4709

Lowell S, Shields JE, Thomas MA, Thommes M (2004) Surface area analysis from the Langmuir and BET theories. In: Characterization of porous solids and powders: surface area, pore size and density. Springer Netherlands, pp 58–81

Rouquerol J, Rouquerol F, Llewellyn P et al (2014) Adsorption by powders and porous solids principles, methodology and applications. Academic Press, Amsterdam

Barrett EP, Joyner LG, Halenda PP (1951) The determination of pore volume and area distributions in porous substances. I. Computations from nitrogen isotherms. J Am Chem Soc 73:373–380. https://doi.org/10.1021/ja01145a126

Zhu Y-J, Chen F (2014) Microwave-assisted preparation of inorganic nanostructures in liquid phase. Chem Rev 114:6462–6555. https://doi.org/10.1021/cr400366s

Valenzano L, Civalleri B, Chavan S et al (2011) Disclosing the complex structure of UiO-66 metal organic framework: a synergic combination of experiment and theory. Chem Mater 23:1700–1718. https://doi.org/10.1021/cm1022882

Visser H, Dubé CE, Armstrong WH et al (2002) FTIR spectra and normal-mode analysis of a tetranuclear manganese adamantane-like complex in two electrochemically prepared oxidation states: relevance to the oxygen-evolving complex of photosystem II. J Am Chem Soc 124:11008–11017. https://doi.org/10.1021/ja020409j

Sharma A, Kaur S, Mahajan CG et al (2007) Fourier transform infrared spectral study of N, N′-dimethylformamide-water-rhodamine 6G mixture. Mol Phys 105:117–123. https://doi.org/10.1080/00268970601146856

Shastri A, Das AK, Krishnakumar S et al (2017) Spectroscopy of N, N-dimethylformamide in the VUV and IR regions: experimental and computational studies. J Chem Phys 147:224305. https://doi.org/10.1063/1.5006126

Amankwah RK, Pickles CA (2009) Thermodynamic, thermogravimetric and permittivity studies of hausmannite (Mn3O4) in air. J Therm Anal Calorim 98:849–853. https://doi.org/10.1007/s10973-009-0273-3

Rosaiah P, Zhu J, Hussain OM, Qiu Y (2018) Graphenothermal reduction synthesis of MnO/RGO composite with excellent anodic behaviour in lithium ion batteries. Ceram Int 44:3077–3084. https://doi.org/10.1016/j.ceramint.2017.11.070

Yang C, Gao Q, Tian W et al (2014) Superlow load of nanosized MnO on a porous carbon matrix from wood fibre with superior lithium ion storage performance. J Mater Chem A 2:19975–19982. https://doi.org/10.1039/C4TA04471A

Biesinger MC, Payne BP, Grosvenor AP et al (2011) Resolving surface chemical states in XPS analysis of first row transition metals, oxides and hydroxides: Cr, Mn, Fe, Co and Ni. Appl Surf Sci 257:2717–2730. https://doi.org/10.1016/j.apsusc.2010.10.051

Ilton ES, Post JE, Heaney PJ et al (2016) XPS determination of Mn oxidation states in Mn (hydr)oxides. Appl Surf Sci 366:475–485. https://doi.org/10.1016/j.apsusc.2015.12.159

Pastoriza-Santos I, Liz-Marzán LM (2009) N, N-dimethylformamide as a reaction medium for metal nanoparticle synthesis. Adv Funct Mater 19:679–688. https://doi.org/10.1002/adfm.200801566

Song A, Yang W, Yang W et al (2017) Facile synthesis of cobalt nanoparticles entirely encapsulated in slim nitrogen-doped carbon nanotubes as oxygen reduction catalyst. ACS Sustain Chem Eng 5:3973–3981. https://doi.org/10.1021/acssuschemeng.6b03173

Lindberg BJ, Hamrin K, Johansson G et al (1970) Molecular spectroscopy by means of ESCA II. Sulfur compounds. Correlation of electron binding energy with structure. Phys Scr 1:286–298. https://doi.org/10.1088/0031-8949/1/5-6/020

Su Y-S, Fu Y, Manthiram A (2012) Self-weaving sulfur–carbon composite cathodes for high rate lithium–sulfur batteries. Phys Chem Chem Phys 14:14495–14499. https://doi.org/10.1039/c2cp42796f

Zhu P, Zhu J, Zang J et al (2017) A novel bi-functional double-layer rGO-PVDF/PVDF composite nanofiber membrane separator with enhanced thermal stability and effective polysulfide inhibition for high-performance lithium–sulfur batteries. J Mater Chem A 5:15096–15104. https://doi.org/10.1039/c7ta03301j

Huang X, Sun B, Li K et al (2013) Mesoporous graphene paper immobilised sulfur as a flexible electrode for lithium–sulfur batteries. J Mater Chem A 1:13484–13489. https://doi.org/10.1039/c3ta12826a

Zhou G, Yin LC, Wang DW et al (2013) Fibrous hybrid of graphene and sulfur nanocrystals for high-performance lithium–sulfur batteries. ACS Nano 7:5367–5375. https://doi.org/10.1021/nn401228t

Chung S-H, Manthiram A (2014) Bifunctional separator with a light-weight carbon-coating for dynamically and statically stable lithium–sulfur batteries. Adv Funct Mater 24:5299–5306. https://doi.org/10.1002/adfm.201400845

Huang JQ, Zhuang TZ, Zhang Q et al (2015) Permselective graphene oxide membrane for highly stable and anti-self-discharge lithium–sulfur batteries. ACS Nano 9:3002–3011. https://doi.org/10.1021/nn507178a

Ma Z, Li Z, Hu K et al (2016) The enhancement of polysulfide absorbsion in Li–S batteries by hierarchically porous CoS2/carbon paper interlayer. J Power Sources 325:71–78. https://doi.org/10.1016/j.jpowsour.2016.04.139

Zhang Z, Wang G, Lai Y, Li J (2016) A freestanding hollow carbon nanofiber/reduced graphene oxide interlayer for high-performance lithium–sulfur batteries. J Alloys Compd 663:501–506. https://doi.org/10.1016/J.JALLCOM.2015.11.120

Hong X-J, Tan T-X, Guo Y-K et al (2018) Confinement of polysulfides within bi-functional metal–organic frameworks for high performance lithium–sulfur batteries. Nanoscale 10:2774–2780. https://doi.org/10.1039/C7NR07118C

Acknowledgements

This work was supported by the Ministry of Education, Youth and Sports of the Czech Republic - Program NPU I (LO1504) and (LO1210). This contribution was written with support of Operational Program Research and Development for Innovations co-funded by the European Regional Development Fund (ERDF) and national budget of Czech Republic, within the framework of project CPS - strengthening research capacity (Reg. Number: CZ.1.05/2.1.00/19.0409). The support by BUT-specific research program (Project No. FEKT-S-17-4595) is gratefully acknowledged. Authors thank Dr. Ondrej Cech for contributing XPS analysis of polysulfide adsorption.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

10853_2019_3871_MOESM1_ESM.docx

Microwave reactor record, Powder XRD after TGA analysis in air, time resolved TGA-FTIR 3D spectrum, SEM-EDX spectrum, XPS survey scans, detailed TEM images, Survey XPS scan of MnO/C sample after Li2S6 adsorption test. (DOCX 5572 kb)

Rights and permissions

About this article

Cite this article

Skoda, D., Kazda, T., Munster, L. et al. Microwave-assisted synthesis of a manganese metal–organic framework and its transformation to porous MnO/carbon nanocomposite utilized as a shuttle suppressing layer in lithium–sulfur batteries. J Mater Sci 54, 14102–14122 (2019). https://doi.org/10.1007/s10853-019-03871-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-03871-4