Abstract

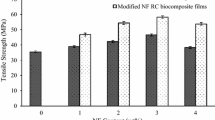

Bio-composites elaboration is limited by poor interfaces between cellulose and polymer matrices and the cellulose degradation. Achieving cellulose grafting with ferulic acid should enhance those resulting bio-composites mechanical properties. Therefore, a cellulose suspension was modified with ferulic acid using laccase under reaction conditions set at 60 °C, acetate buffer pH 5 for 24 h. Grafted cellulose fibrils were extruded in polypropylene-grafted maleic acid (PPgMA) for mechanical properties studies. Even if ferulic acid interacted with cellulose without any enzyme presence, the acid resilience was only detected for cellulose fibres modified with ferulic acid proving the surface grafting. Cellulose fibrillary lengths were unaffected by the enzymatic treatment suggesting a tiny coating. The resulting bio-composites had a Young modulus reduction of 12%. The elongation at maximal stress had 23% improvement, corresponding to a material mechanical resistance. This result was also confirmed by bio-composite elaboration with natural fibres under the same conditions. Ferulic acid and cellulose blends have improved the hardness properties of the resulting bio-composites with PP-PPgMA.

Similar content being viewed by others

References

Yan L, Chouw N, Jayaraman K (2014) Flax fibre and its composites – A review. Compos B Eng 56:296–317. https://doi.org/10.1016/j.compositesb.2013.08.014

Ravi M, Dubey RR, Shome A et al (2018) Effect of surface treatment on natural fibers composite. IOP Conf Ser Mater Sci Eng 376:012053. https://doi.org/10.1088/1757-899X/376/1/012053

Jandura P, Riedl B, Kokta BV (2000) Thermal degradation behavior of cellulose fibers partially esterified with some long chain organic acids. Polym Degrad Stab 70:387–394. https://doi.org/10.1016/S0141-3910(00)00132-4

Nada AMA, Hassan ML (2000) Thermal behavior of cellulose and some cellulose derivatives. Polym Degrad Stab 67:111–115. https://doi.org/10.1016/S0141-3910(99)00100-7

Zimniewska M, Wladyka-Przybylak M, Mankowski J (2011) Cellulosic bast fibers, their structure and properties suitable for composite applications. In: Kalia S, Kaith BS, Kaur I (eds) Cellulose fibers: bio- and nano-polymer composites. Springer, Berlin, pp 97–119

Temmerman E, Akishev Y, Trushkin N et al (2005) Surface modification with a remote atmospheric pressure plasma: dc glow discharge and surface streamer regime. J Phys D Appl Phys 38:505–509. https://doi.org/10.1088/0022-3727/38/4/001

Burrola-Núñez H, Herrera-Franco PJ, Rodríguez-Félix DE et al (2018) Surface modification and performance of jute fibers as reinforcement on polymer matrix: an overview. J Nat Fibers 1–17. https://doi.org/10.1080/15440478.2018.1441093

Agrawal R, Saxena NS, Sharma KB et al (2000) Activation energy and crystallization kinetics of untreated and treated oil palm fibre reinforced phenol formaldehyde composites. Mater Sci Eng A 277:77–82. https://doi.org/10.1016/S0921-5093(99)00556-0

Li X, Tabil LG, Panigrahi S (2007) Chemical treatments of natural fiber for use in natural fiber-reinforced composites: a review. J Polym Environ 15:25–33. https://doi.org/10.1007/s10924-006-0042-3

Doherty WOS, Mousavioun P, Fellows CM (2011) Value-adding to cellulosic ethanol: lignin polymers. Ind Crops Prod 33:259–276. https://doi.org/10.1016/j.indcrop.2010.10.022

Marjamaa K, Kruus K (2018) Enzyme biotechnology in degradation and modification of plant cell wall polymers. Physiol Plant 164:106–118. https://doi.org/10.1111/ppl.12800

Kharazipour A, Mai C, Hüttermann A (1998) Polyphenoles for compounded materials. Polym Degrad Stab 59:237–243. https://doi.org/10.1016/S0141-3910(97)00157-2

Aracri E, Roncero MB, Vidal T (2011) Studying the effects of laccase-catalysed grafting of ferulic acid on sisal pulp fibers. Biores Technol 102:7555–7560. https://doi.org/10.1016/j.biortech.2011.05.046

Hüttermann A, Majcherczyk A, Braun-Lüllemann A et al (2000) Enzymatic activation of lignin leads to an unexpected copolymerization with carbohydrates. Naturwissenschaften 87:539–541

Slagman S, Zuilhof H, Franssen MCR (2018) Laccase-mediated grafting on biopolymers and synthetic polymers: a critical review. ChemBioChem 19:288–311. https://doi.org/10.1002/cbic.201700518

Sluiter A, Hames B, Ruiz R et al (2012) Determination of structural carbohydrates and lignin in biomass. LAP 1–18

Sohn YT, Oh JH (2003) Characterization of physicochemical properties of ferulic acid. Arch Pharmacal Res 26:1002–1008. https://doi.org/10.1007/BF02994749

AL-Oqla FM, Sapuan SM (2014) Natural fiber reinforced polymer composites in industrial applications: feasibility of date palm fibers for sustainable automotive industry. J Clean Prod 66:347–354. https://doi.org/10.1016/j.jclepro.2013.10.050

French AD (2014) Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 21:885–896. https://doi.org/10.1007/s10570-013-0030-4

Acknowledgements

The authors would like to acknowledge Alexandre Schandeler for his technical help and his wise recommendations about this project. This project was supported by the INTERREG France-Wallonie-Vlanderen Call V which granted this work as part of the COMPOSENS project. The authors also would like to thank Prof. Dr. Ir. Blecker Laboratory (University of Liège, Belgium) who has kindly given access to the TGA and DSC apparatus. The authors are grateful to the laboratory of Prof. Damblon (University of Liège-Belgium) for NMR profile and Prof. Vertruyen (University of Liège, Belgium) for the XRD diffractograms. We also express our gratitude to the CERTECH (Seneffe, Belgium) which kindly performed the bio-composites extrusion and the tensile test.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Morin, S., Bockstal, L., Jacquet, N. et al. One-step enzymatic grafting of ferulic acid with cellulose to enhance matrices–fibres compatibility in bio-composites. J Mater Sci 54, 13314–13321 (2019). https://doi.org/10.1007/s10853-019-03832-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-03832-x