Abstract

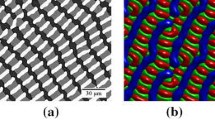

In this work, the directional solidification of NiZr–NiZr\(_2\) eutectics under isothermal conditions is investigated through numerical and theoretical means. Multiple three-dimensional phase-field simulations, including a large-scale simulation, are performed to study the free pattern selection and the velocity–spacing relation of the evolving solidification microstructures. The computed velocities for different spacings of the stoichiometric NiZr rods in the as-well stoichiometric NiZr\(_2\) matrix are compared with the predictions of the classical Jackson–Hunt analysis. Due to certain simplifying assumptions invoked in the original theory which are not entirely representative of the numerically realized microstructures, significant deviations are observed between the two. In view of this, an extended theory is formulated accounting for the global hexagonal arrangement of the evolving rods as well as the solidification front curvatures. Owing to that, a superior compliance is achieved between the analytical and simulated growth kinetics. The key elements of symmetry incorporation are of particular importance, especially in applications to ternary systems.

Similar content being viewed by others

References

Basu J, Murty BS, Ranganathan S (2008) Glass forming ability: miedema approach to (Zr, Ti, Hf)–(Cu, Ni) binary and ternary alloys. J Alloys Compd 465(1):163–172

Dong YD, Gregan G, Scott MG (1981) Formation and stability of Nickel–Zirconium glasses. J Non-Cryst Solids 43(3):403–415

Huang L, Li S (2013) Glass formation in Ni–Zr–(Al) alloy systems. J Mater 2013:575640

Smith JF, Jiang Q, Lück R, Predel B (1991) The heat capacities of solid Ni–Zr alloys and their relationship to the glass transition. J Phase Equilib 12(5):538–545

Ray R, Szymanski D (1973) Electron diffraction study of a noncrystalline Zr–Ni phase. Metall Mater Trans B 4(8):1785–1790

Altounian Z, Guo-hua T, Strom-Olsen JO (1983) Crystallization characteristics of Ni–Zr metallic glasses from Ni20Zr80 to Ni70Zr30. J Appl Phys 54(6):3111–3116

Kobold R, Kuang WW, Wang H, Hornfeck W, Kolbe M, Herlach DM (2017) Dendrite growth velocity in the undercooled melt of glass forming Ni50Zr50 compound. Philos Mag Lett 97(6):249–256

Kobold R (2016) Crystal growth in undercooled melts of glass forming Zr-based alloys. PhD thesis, Ruhr-Universität Bochum, Universitätsbibliothek

Zaitsev AI, Zaitseva NE, Shakhpazov EK, Kodentsov AA (2002) Thermodynamic properties and phase equilibria in the Nickel–Zirconium system. The liquid to amorphous state transition. Phys Chem Chem Phys 4(24):6047–6058

Shao G (2000) Prediction of amorphous phase stability in metallic alloys. J Appl Phys 88(7):4443–4445

Ghosh G (1994) Thermodynamics and kinetics of stable and metastable phases in the Ni–Zr system. J Mater Res 9(3):598–616

Abe T, Onodera H, Shimono M, Ode M (2005) Thermodynamic modeling of the undercooled liquid in the Ni–Zr system. Mater Trans 46(12):2838–2843

Voigtmann T, Meyer A, Holland-Moritz D, Stüber S, Hansen T, Unruh T (2008) Atomic diffusion mechanisms in a binary metallic melt. EPL (Europhys Lett) 82(6):66001

Holland-Moritz D, Stüber S, Hartmann H, Unruh T, Meyer A (2009) Ni self-diffusion in Zr–Ni(–Al) melts. Int J Phys Conf Ser 144:012119

Altounian Z, Guo-hua T, Strom-Olsen JO (1982) Crystallization characteristics of Cu–Zr metallic glasses from Cu70Zr30 to Cu25Zr75. J Appl Phys 53(7):4755–4760

The experiments are conducted as part of the current work

Tan Y, Li J, Wang J, Kolbe M, Kou H (2018) Microstructure characterization of CoCrFeNiMnPdx eutectic high-entropy alloys. J Alloys Compd 731:600–611

Hötzer J, Kellner M, Steinmetz P, Nestler B (2016) Applications of the phase-field method for the solidification of microstructures in multi-component systems. J Indian Inst Sci 96(3):235–256

Hötzer J, Jainta M, Steinmetz P, Nestler B, Dennstedt A, Genau A, Bauer M, Köstler H, Rüde U (2015) Large scale phase-field simulations of directional ternary eutectic solidification. Acta Mater 93:194–204

Hötzer J, Steinmetz P, Dennstedt A, Genau A, Kellner M, Sargin I, Nestler B (2017) Influence of growth velocity variations on the pattern formation during the directional solidification of ternary eutectic Al–Ag–Cu. Acta Mater. 136:335–346

Steinmetz P, Kellner M, Hötzer J, Dennstedt A, Nestler B (2016) Phase-field study of the pattern formation in Al–Ag–Cu under the influence of the melt concentration. Comput Mater Sci 121:6–13

Noubary KD, Kellner M, Steinmetz P, Hötzer J, Nestler B (2017) Phase-field study on the effects of process and material parameters on the tilt angle during directional solidification of ternary eutectics. Comput Mater Sci 138:403–411

Kim SG, Kim WT, Suzuki T, Ode M (2004) Phase-field modeling of eutectic solidification. J Cryst Growth 261(1):135–158

Choudhury A, Plapp M, Nestler B (2011) Theoretical and numerical study of lamellar eutectic three-phase growth in ternary alloys. Phys Rev E 83(5):051608

Plapp M, Bottin-Rousseau S, Faivre G, Akamatsu S (2017) Eutectic solidification patterns: interest of microgravity environment. CR Mécanique 345(1):56–65

Plapp M (2007) Three-dimensional phase-field simulations of directional solidification. J Cryst Growth 303(1):49–57

Parisi A, Plapp M, Akamatsu S, Bottin-Rousseau S, Perrut M, Faivre G (2005) Three-dimensional phase-field simulations of eutectic solidification and comparison to in situ experimental observations. TMS (The Minerals, Metals & Materials Society)

Parisi A, Plapp M (2008) Stability of lamellar eutectic growth. Acta Mater 56(6):1348–1357

Plapp M, Karma A (2002) Eutectic colony formation: a phase-field study. Phys Rev E 66(6):061608

Lahiri A, Tiwary C, Chattopadhyay K, Choudhury A (2017) Eutectic colony formation in systems with interfacial energy anisotropy: a phase field study. Comput Mater Sci 130:109–120

Pusztai T, Rátkai L, Szállás A, Gránásy L (2013) Spiraling eutectic dendrites. Phy Rev E 87(3):032401

Hötzer J, Steinmetz P, Jainta M, Schulz S, Kellner M, Nestler B, Genau A, Dennstedt A, Bauer M, Köstler H et al (2016) Phase-field simulations of spiral growth during directional ternary eutectic solidification. Acta Mater 106:249–259

Rátkai L, Szállás A, Pusztai T, Mohri T, Gránásy L (2015) Ternary eutectic dendrites: pattern formation and scaling properties. J Chem Phys 142(15):154501

Steinmetz P, Hötzer J, Kellner M, Dennstedt A, Nestler B (2016) Large-scale phase-field simulations of ternary eutectic microstructure evolution. Comput Mater Sci 117:205–214

Kellner M, Sprenger I, Steinmetz P, Hötzer J, Nestler B, Heilmaier M (2017) Phase-field simulation of the microstructure evolution in the eutectic NiAl–34Cr system. Comput Mater Sci 128:379–387

Yanli L, Jia D, Tingting H, Chen Z, Zhang L (2014) Phase-field study of the effects of elastic strain energy on the occupation probability of Cr atom in Ni–Al–Cr alloy. Superlattice Microst 66:105–111

Wu K, Chang YA, Wang Y (2004) Simulating interdiffusion microstructures in Ni–Al–Cr diffusion couples: a phase field approach coupled with calphad database. Scripta Mater 50(8):1145–1150

Jackson KA, Hunt JD (1966) Lamellar and rod eutectic growth. AIME Met Soc Trans 236:1129–1142

Donaghey LF, Tiller WA (1968) On the diffusion of solute during the eutectoid and eutectic transformations, part I. Mater Sci Eng 3(4):231–239

Trivedi R, Magnin P, Kurz W (1987) Theory of eutectic growth under rapid solidification conditions. Acta Metall 35(4):971–980

Himemiya T, Umeda T (1999) Three-phase planar eutectic growth models for a ternary eutectic system. Mater Trans JIM 40(7):665–674

Zheng LL, Larson DJ Jr, Zhang H (2000) Revised form of Jackson–Hunt theory: application to directional solidification of MnBi/Bi eutectics. J Cryst Growth 209(1):110–121

Ludwig A, Leibbrandt S (2004) Generalised ‘Jackson–Hunt’model for eutectic solidification at low and large peclet numbers and any binary eutectic phase diagram. Mater Sci Eng A 375:540–546

Liu S, Lee JH, Trivedi R (2011) Dynamic effects in the lamellar-rod eutectic transition. Acta Mater 59(8):3102–3115

Ankit K, Choudhury A, Qin C, Schulz S, McDaniel M, Nestler B (2013) Theoretical and numerical study of lamellar eutectoid growth influenced by volume diffusion. Acta Mater 61(11):4245–4253

Catalina AV, Voorhees PW, Huff RK, Genau AL (2015) A model for eutectic growth in multicomponent alloys. In: IOP conference series: materials science and engineering. vol 84, pp. 012085. IOP Publishing

Senninger O, Voorhees PW (2016) Eutectic growth in two-phase multicomponent alloys. Acta Mater 116:308–320

Lahiri A, Choudhury A (2017) Revisiting Jackson-Hunt calculations: unified theoretical analysis for generic multi-phase growth in a multi-component system. Acta Mater 133:316–332

Nani ES, Nestler B, Ankit K (2018) Analyzing the cooperative growth of intermetallic phases with a curved solidification front. Acta Mater 159:135–149

Nani ES, Nestler B (2019) Extension of Jackson–Hunt analysis for curved solid–liquid interfaces. J Cryst Growth 512:230–240

Plapp M (2011) Unified derivation of phase-field models for alloy solidification from a grand-potential functional. Phys Rev E 84(3):031601

Choudhury A, Nestler B (2012) Grand-potential formulation for multicomponent phase transformations combined with thin-interface asymptotics of the double-obstacle potential. Phys Rev E 85(2):021602

Hashimoto K, Abe T (2007) NiZr. Calphad database. Particle Simulation and Thermodynamics Group, National Institute for Materials Science, 2

Hu SY, Murray J, Weiland H, Liu ZK, Chen LQ (2007) Thermodynamic description and growth kinetics of stoichiometric precipitates in the phase-field approach. Calphad 31(2):303–312

Nakajima H, Sprengel W, Nonaka K (1996) Diffusion in intermetallic compounds. Intermetallics 4:S17–S28

Vondrous A, Selzer M, Hötzer J, Nestler B (2013) Parallel computing for phase-field models. Int J High Perform C. https://doi.org/10.1144/1094342013490972

Hötzer J, Reiter A, Hierl H, Steinmetz P, Selzer M, Nestler B (2018) The parallel multi-physics phase-field framework pace3d. J Comput Sci 26:1–12

Hötzer J, Tschukin O, Said MB, Berghoff M, Jainta M, Barthelemy G, Smorchkov N, Schneider D, Selzer M, Nestler B (2015) Calibration of a multi-phase field model with quantitative angle measurement. J Mater Sci 51(4):1788–1797. https://doi.org/10.1007/s10853-015-9542-7

Wang F, Choudhury A, Nestler B (2012) Solidification morphologies in monotectic alloys. In: IOP conference series: materials science and engineering. vol 27, pp 012027. IOP Publishing

Choudhury A, Geeta M, Nestler B (2013) Influence of solid–solid interface anisotropy on three-phase eutectic growth during directional solidification. EPL (Europhys Lett) 101(2):26001

Parisi A, Plapp M (2010) Defects and multistability in eutectic solidification patterns. EPL (Europhys Lett) 90(2):26010

Kellner M, Kunz W, Steinmetz P, Hötzer J, Nestler B (2018) Phase-field study of dynamic velocity variations during directional solidification of eutectic NiAl–34Cr. Comput Mater Sci 145:291–305

Kellner M, Sprenger I, Steinmetz P, Hötzer J, Nestler B, Heilmaier M (2017) Phase-field simulation of the microstructure evolution in the eutectic NiAl–34Cr system. Comput Mater Sci 128:379–387

Steinmetz P, Hötzer J, Kellner M, Genau A, Nestler B (2018) Study of pattern selection in 3D phase-field simulations during the directional solidification of ternary eutectic Al–Ag–Cu. Comput Mater Sci 148:131–140

Kurz W (2011) Eutectic growth before and after Jackson and Hunt 1966. In: Fan Z, Stone IC (eds) Proceedings of the John Hunt International Symposium. pp 1–15

Acknowledgements

The authors gratefully acknowledge funding by the German Research Foundation (DFG) through Grant Number NE \(822/22-1\).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Enugala, S.N., Kellner, M., Kobold, R. et al. Theoretical and numerical investigations of rod growth of an Ni–Zr eutectic alloy. J Mater Sci 54, 12605–12622 (2019). https://doi.org/10.1007/s10853-019-03802-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-03802-3