Abstract

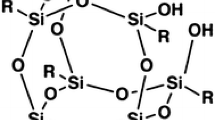

Trisilanol phenyl polyhedral silsesquioxane (phenyl TSP) was added to a commercial aluminum alloy, AlSi10MnMg, to investigate its influence on microstructure, mechanical properties, and solidification behavior. Addition of phenyl TSP was successful in refining the morphology of the eutectic Si into an ultrafine lamellar structure. Furthermore, this refined as-cast morphology can be obtained even when the molten aluminum alloy was held for 96 h in a furnace set at around 1000 K. This no fading phenomenon is of a significant processing benefit to the current use of Sr for refining the eutectic morphology. The ductility of phenyl TSP-refined AlSi10MnMg alloy was consistent with Sr-modified alloy at room, 423 K, and 573 K elevated temperature while maintaining similar strength. Cooling curve analysis showed the Al–Si eutectic arrest temperatures during solidification were decreased with the phenyl TSP addition, suggesting phenyl TSP bonds with Al to slow down the Al segregation from Al–Si melt during the eutectic reaction, leading to the microstructural refinement of Al–Si eutectic.

Similar content being viewed by others

References

Luk JM, Kim HC, De Kleine R, Wallington TJ, MacLean HL (2017) Review of the fuel saving, life cycle ghg emission, and ownership cost impacts of lightweighting vehicles with different powertrains. Environ Sci Technol 51:8215–8228

Kim HC, Wallington TJ (2016) Life cycle assessment of vehicle lightweighting: a physics-based model to estimate use-phase fuel consumption of electrified vehicles. Environ Sci Technol 50:11226–11233

Peretz JH, Das S, Tonn BE (2009) Evaluating knowledge benefits of automotive lightweighting materials R&D projects. Eval Program Plan 32:300–309

Dahle A, Nogita K, McDonald S, Dinnis C, Lu L (2005) Eutectic modification and microstructure development in Al–Si alloys. Mater Sci Eng, A 413:243–248

Birol Y (2012) Performance of AlTi5B1, AlTi3B3 and AlB3 master alloys in refining grain structure of aluminium foundry alloys. Mater Sci Technol Lond 28:481–486

Sigworth G (2008) The modification of Al–Si casting alloys: important practical and theoretical aspects. Int J Metalcast 2:19–41

Zuo M, Zhao D, Teng X, Geng H, Zhang Z (2013) Effect of P and Sr complex modification on Si phase in hypereutectic Al–30Si alloys. Mater Des 47:857–864

Eisaabadi G, Nouri A (2018) Effect of Sr on the microstructure of electromagnetically stirred semi-solid hypoeutectic Al–Si alloys. Int J Metalcast 12:292–297

Farahany S, Ourdjini A, Idris MH, Thai LT (2011) Poisoning effect of bismuth on modification behaviour of strontium in LM25 alloy. Bull Mater Sci 34:1223–1231

Cho YH, Lee H-C, Oh KH, Dahle AK (2008) Effect of strontium and phosphorus on eutectic Al–Si nucleation and formation of β-Al5FeSi in hypoeutectic Al–Si foundry alloys. Metall Mater Trans A 39:2435–2448

Lee A, Subramanian K (2005) Development of nano-composite lead-free electronic solders. J Electron Mater 34:1399–1407

Choudhuri D (2009) Influence of nano-structured chemicals on the microstructures and mechanical reliability of lead-free tin-based solders. Michigan State University, East Lansing

Hoebbel D, Reinert T, Schmidt H (1996) 29 Si NMR investigation of condensation reactions of diphenylsilanediol in presence of Ti-, Zr-, Al-, Sn-and Si-alkoxides. J Sol Gel Sci Technol 7:217–224

Fina A, Tabuani D, Carniato F, Frache A, Boccaleri E, Camino G (2006) Polyhedral oligomeric silsesquioxanes (POSS) thermal degradation. Thermochim Acta 440:36–42

Lee A, Lu Y, Roche A, Pan T-Y (2016) Influence of nano-structured silanols on the microstructure and mechanical properties of A4047 and A359 aluminum casting alloys. Int J Metalcasting 10:338–341

Dahle A, Nogita K, McDonald S, Zindel J, Hogan L (2001) Eutectic nucleation and growth in hypoeutectic Al–Si alloys at different strontium levels. Metall Mater Trans A 32:949–960

Wagner RS (1960) On the growth of germanium dendrites. Acta Metall Mater 8:57–60

Hamilton DR, Seidensticker RG (1960) Propagation mechanism of germanium dendrites. J Appl Phys 31:1165–1168

Kobayashi KF, Hogan LM (1985) The crystal-growth of silicon in Al–Si alloys. J Mater Sci 20:1961–1975. https://doi.org/10.1007/BF01112278

Day MG, Hellawel A (1968) Microstructure and crystallography of aluminium–silicon eutectic alloys. Proc R Soc Lond Ser A 305:473–491

Lu SZ, Hellawell A (1987) The mechanism of silicon modification in aluminum–silicon alloys—impurity induced twinning. Metall Trans A 18:1721–1733

Acknowledgements

YL and AL acknowledge the financial support from Ford Motor Company through a Ford-MSU Alliance Program.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lu, Y., Godlewski, L.A., Zindel, J.W. et al. Use of reactive nanostructured chemicals for refinement of Si eutectic in an aluminum casting alloy. J Mater Sci 54, 12818–12832 (2019). https://doi.org/10.1007/s10853-019-03799-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-03799-9