Abstract

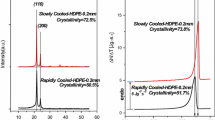

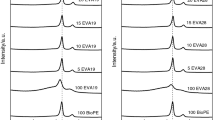

High-density polyethylene becomes optically transparent during tensile drawing when previously saturated with diesel fuel. This unusual phenomenon is investigated as it might allow conclusions with respect to the material behavior. Microscopy, differential scanning calorimetry, density measurements are applied together with two scanning X-ray scattering techniques: wide angle X-ray scattering (WAXS) and X-ray refraction, able to extract the spatially resolved crystal orientation and internal surface, respectively. The sorbed diesel softens the material and significantly alters the yielding characteristics. Although the crystallinity among stretched regions is similar, a virgin reference sample exhibits strain whitening during stretching, while the diesel-saturated sample becomes transparent. The WAXS results reveal a pronounced fiber texture in the tensile direction in the stretched region and an isotropic orientation in the unstretched region. This texture implies the formation of fibrils in the stretched region, while spherulites remain intact in the unstretched parts of the specimens. X-ray refraction reveals a preferred orientation of internal surfaces along the tensile direction in the stretched region of virgin samples, while the sample stretched in the diesel-saturated state shows no internal surfaces at all. Besides from stretching saturated samples, optical transparency is also obtained from sorbing samples in diesel after stretching.

Similar content being viewed by others

References

Bunn CW (1939) The crystal structure of long-chain normal paraffin hydrocarbons. The “shape” of the > CH2 group. Trans Faraday Soc 35:482–491

Strobl GR (2007) The physics of polymers. Springer-Verlag, Berlin, pp 165–225

Sperling LH (2005) The crystalline state. In: Sperling LH (ed) Introduction to physical polymer science. Wiley, London, pp 239–324

Baccaredda M, Schiavinato G (1954) Refractive indices of polythenes with different degrees of branching. J Polym Sci 12:155–158

Bryant WMD (1947) Polythene fine structure. J Polym Sci 2:547–564

Hay IL, Keller A (1965) Polymer deformation in terms of spherulites. Kolloid Z u Z Polym 204:43–74

Meinel G, Morosoff N, Peterlin A (1970) Plastic deformation of polyethylene. I. Change of morphology during drawing of polyethylene of high density. J Polym Sci Part A-2: Polym Phys 8:1723–1740

Meinel G, Peterlin A (1971) Plastic deformation of polyethylene II. Change of mechanical properties during drawing. J Polym Sci Part A-2: Polym Phys 9:67–83

Pawlak A, Gałęski A (2010) Cavitation during tensile drawing of annealed high density polyethylene. Polymer 51:5771–5779

Pawlak A, Gałęski A, Różański A (2014) Cavitation during deformation of semicrystalline polymers. Pro Polym Sci 39:921–958

Lin L, Argon AS (1994) Structure and plastic deformation of polyethylene. J Mater Sci 29:294–323. https://doi.org/10.1007/BF01162485

Różański A, Gałęski A (2011) Controlling cavitation of semicrystalline polymers during tensile drawing. Macromolecules 44:7273–7287

Gałęski A, Różański A (2010) Cavitation during drawing of crystalline polymers. Macromol Symp 298:1–9

Men Y, Rieger J, Homeyer J (2004) Synchrotron ultrasmall-angle X-ray scattering studies on tensile deformation of poly(1-butene). Macromolecules 37:9481–9488

Lu Y, Men Y (2018) Cavitation-induced stress whitening in semi-crystalline polymers. Macromol Mater Eng 303:1800203

Pawlak A (2007) Cavitation during tensile deformation of high-density polyethylene. Polymer 48:1397–1409

Peterlin A (1975) Plastic deformation of polymers with fibrous structure. J Colloid Polym Sci 253:809–823

Peterlin A (1975) Structural model of mechanical properties and failure of crystalline polymer solids with fibrous structure. Int J Fract 11:761–780

Pawlak A, Gałęski A (2011) Cavitation during tensile drawing of semicrystalline polymers. Polimery 56:627–636

Butler MF, Donald AM (1998) A real-time simultaneous small- and wide-angle X-ray scattering study of in situ polyethylene deformation at elevated temperatures. Macromolecules 3:6234–6249

Jiang Z, Tang Y, Rieger J, Enderle HF, Lilge D, Roth SV, Gehrke R, Wu Z, Li Z, Li X, Men Y (2010) Structural evolution of melt-drawn transparent high-density polyethylene during heating and annealing: synchrotron small-angle X-ray scattering study. Eur Polym J 46:1866–1877

Różański A, Gałęski A (2013) Plastic yielding of semicrystalline polymers affected by amorphous phase. Int J Plast 41:14–29

Erdmann M, Böhning M, Niebergall U (2019) Physical and chemical effects of biodiesel storage on high-density polyethylene: evidence of co-oxidation. Polym Degrad Stabil 161:139–149

Böhning M, Niebergall U, Zanotto M, Wachtendorf V (2016) Impact of biodiesel sorption on tensile properties of PE-HD for container applications. Polym Test 50:315–324

Immergut EH, Mark HF (1965) Principles of plasticization. In: Platzer NAJ (ed) Plasticization and plasticizer processes, advances in chemistry. American Chemical Society, Washington, pp 1–26

Wypych G (2017) Handbook of plasticizers, 3rd edn. ChemTec Publishing, Toronto, pp 3–6

Böhning M, Niebergall U, Adam A, Stark W (2014) Impact of biodiesel sorption on mechanical properties of polyethylene. Polym Test 34:17–24

ISO 293:2004 (2004) Plastics—compression moulding of test specimens of thermoplastic materials, pp 1–6

ISO 527-2:2012 (2012) Plastics—determination of tensile properties—part 2: test conditions for moulding and extrusion plastics, pp 1–11

EN 590:2013+AC:2014 (2014) Automotive fuels—Diesel—Requirements and test methods; German version, pp 1–11

Wunderlich B, Cormier CM (1967) Heat of fusion of polyethylene. J Polym Sci Part A-2: Polym Phys 5:987–988

Laue MTF, Wagner EH (1960) Röntgenstrahl-Interferenzen. Akademische Verlagsgesellschaft, Frankfurt am Main, pp 123–140

Hentschel MP, Hosemann R, Lange A, Uther B, Brückner R (1987) Small-angle X-ray refraction in metal wires, glass-fibers and hard elastic propylenes. Acta Crystallogr A 43:506–513

Evsevleev S, Müller BR, Lange A, Kupsch A (2019) Refraction driven X-ray caustics at curved interfaces. Nucl Instrum Methods Phys Res A 916:275–282

Hentschel MP, Harbich KW, Ekenhorst D, Schors J (1997) X-ray topographic methods for composite fibre and matrix orientation. Materialprüfung 39:121–123

Kupsch A, Lange A, Hentschel MP, Onel Y, Wolk T, Staude A, Ehrig K, Müller BR, Bruno G (2013) Evaluating porosity in cordierite-based diesel particulate filter materials. Part 1—X-ray refraction. J Ceram Sci Tech 4:169–176

Kupsch A, Müller BR, Lange A, Bruno G (2017) Microstructure characterization of ceramics via 2D and 3D X-ray refraction techniques. J Eur Ceram Soc 37:1879–1889

Müller BR, Cooper RC, Lange A, Kupsch A, Wheeler M, Hentschel MP, Staude A, Pandey A, Shyam A, Bruno G (2018) Stress-induced microcrack density evolution in ß-eucryptite ceramics: experimental observations and possible route to strain hardening. Acta Mater 144:627–641

Nellesen J, Laquai L, Müller BR, Kupsch A, Hentschel MP, Anar NB, Soppa E, Tillmann W, Bruno G (2018) In situ analysis of damage evolution in an Al/Al2O3 MMC under tensile load by synchrotron X-ray refraction imaging. J Mater Sci 53:6021–6032. https://doi.org/10.1007/s10853-017-1957-x

Laquai R, Müller BR, Kasperovich G, Haubrich J, Requena G, Bruno G (2018) X-ray refraction distinguishes unprocessed powder from empty pores in selective laser melting Ti–6Al–4V. Mater Res Lett 6:130–135

Glatter O, Kratky O (1982) Small angle X-ray scattering. Academic Press Inc. Ltd, London, pp 53–83

Fensch-Kleemann FE, Harbich KW, Hentschel MP (2002) Microstructural characterisation of porous ceramics by X-Ray refraction topography, cfi/Ber. DKG 79:35–38

Zhang Y, Ben Jar BY, Xue S, Li L (2019) Quantification of strain-induced damage in semi-crystalline polymers: a review. J Mater Sci 54:62–82. https://doi.org/10.1007/s10853-018-2859-2

Gooch JW (ed) (2007) Encyclopedic dictionary of polymers. Springer, New York, p 1081

Wunderlich B, Czornyj G (1977) A study of equilibrium melting of polyethylene. Macromolecules 10:906–913

Bartczak Z, Gałęski A (2010) Plasticity of semicrystalline polymers. Macromol Symp 294:67–90

Jiang Z, Tang Y, Rieger J, Enderle HF, Lilge D, Roth SV, Gehrke R, Wu Z, Li Z, Men Y (2009) Structural evolution of tensile deformed high-density polyethylene at elevated temperatures: scanning synchrotron small- and wide-angle X-ray scattering studies. Polymer 50:4101–4111

Kono A, Miyakawa N, Kawadai S, Goto Y, Maruoka T, Yamamoto M, Horibe H (2010) Effect of cooling rate after polymer melting on electrical properties of high-density polyethylene/Ni composites. Polym J 42:587–591

Hiss R, Hobeika S, Lynn C, Strobl G (1999) Network stretching, slip processes, and fragmentation of crystallites during uniaxial drawing of polyethylene and related copolymers. A comparative study. Macromolecules 32:4390–4403

Acknowledgements

The authors kindly acknowledge Oliver Schwarze and Fabian Roth for the preparation of the tensile test specimens. We thank Thomas Rybak for the assistance with DSC measurements and Lothar Buchta for the assistance with optical pictures. This study was supported by BAM within the project “Microbial Induced Corrosion” in the focus area “Material”.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Erdmann, M., Kupsch, A., Müller, B.R. et al. Diesel-induced transparency of plastically deformed high-density polyethylene. J Mater Sci 54, 11739–11755 (2019). https://doi.org/10.1007/s10853-019-03700-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-019-03700-8