Abstract

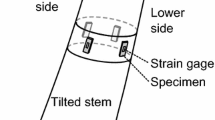

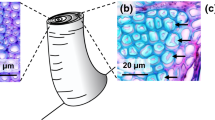

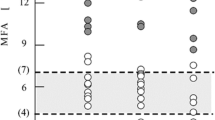

To clarify the mechanism of irreversible dimensional changes due to the hygrothermal treatment of green wood, i.e., the hygrothermal recovery (HTR), the changes in vibrational properties of compression wood and normal wood were measured after hygrothermal treatment at 60 °C, 80 °C, and 100 °C. In addition, the relationship between those changes and HTR strains were discussed. The hygrothermal treatment induced an increase in mechanical loss tangent (tanδ) and decrease in specific dynamic Young’s modulus (E′/ρ). It seems that the changes in vibrational properties due to hygrothermal treatment had a time–temperature dependency: Higher temperatures and longer treatment durations induce larger increases in tanδ and larger decreases in E′/ρ. In contrast to the quenching effect, tanδ and E′/ρ did not recover to their original state even after 60 days of conditioning in water at 20 °C. For compression wood with a large microfibril angle (MFA), there was a clear relationship between the changes in vibrational properties and HTR strains. The tanδ increased and E′/ρ decreased with hygrothermal treatment, corresponding to dimensional changes in the L-direction. This suggests that structural changes in wood components are responsible for HTR. The most likely mechanism for HTR is that the hygrothermal treatment softens the lignin to release locked-in growth stress. Subsequently, irreversible structural changes in lignin induce both the changes in vibrational properties and HTR. For normal wood, because of the small MFA, the structural changes in lignin in the L-direction are possibly restricted by crystalline cellulose. As a result, the relationship between the changes in vibrational properties and HTR is uncertain.

Similar content being viewed by others

References

Kübler H (1959) Studien über Wachstumsspannungen des Holzes - Dritte Mitteilung: längenäderungen bei der Wärmebehandlung frischen Holzes (Studies of growth stresses in tress Part 3. Effect of heat treatment on the dimensions of green wood. Holz Roh-Werk 17:77–86 (In German)

Yokota T, Tarkow H (1962) Changes in dimension on heating green wood. Forest Prod J 12:43–45

Kübler H (1987) Growth stresses in tress and related properties. For Prod Abstr 10:61–119

Archer RR (1987) Growth stresses and strains in trees. Springer, Berlin

Yamamoto H (1998) Generation mechanism of growth stresses in wood cell walls: roles of lignin deposition and cellulose microfibril during cell wall maturation. Wood Sci Technol 32:171–182

Gril J, Jullien D, Bardet S, Yamamoto H (2017) Tree growth stress and related problems. J Wood Sci 63:411–432

Sasaki Y, Okuyama T (1983) Residual stress and dimensional changes on heating green wood. Mokuzai Gakkaishi 29(4):302–307

Tanaka M, Yamamoto H, Kojima M, Yoshida M, Matsuo M, Lahjie Abubakar M, Hongo I, Arizono T (2014) The interrelation between microfibril angle (MFA) and hygrothermal recovery (HTR) in compression wood and normal wood of Sugi and Agathis. Holzforshung 68(7):823–830

Toba K, Yamamoto H, Yoshida M (2013) Micromechanical detection of growth stress in wood cell wall by wide angle X-ray diffraction (WAX). Holzforshung 67:315–323

Matsuo UM, Niimi G, Sujan KC, Yoshida M, Yamamoto H (2016) Hygrothermal recovery of compression wood in relation to elastic growth stress and its physicochemical characteristics. J Mater Sci 51:7956–7965. https://doi.org/10.1007/s10853-016-0065-7

Yano H (1994) The changes in the acoustic properties of Western Red Cedar due to methanol extraction. Holzforshung 48:491–495

Obataya E, Umezawa T, Nakatsubo F, Norimoto M (1999) The effects of water-soluble extractives on the acoustic properties of reed (Arundo donax L.). Holzforschung 53:63–67

Matsunaga M, Minato K, Nakatsubo F (1999) Vibrational properties changes of spruce wood by impregnation with water-soluble extractives of Pernambuco (Guilandina echinata Spreng). J Wood Sci 45:470–474

Minato K, Konaka Y, Brémaud I, Suzuku S, Obataya E (2010) Extractives of muirapiragna (Brsosium sp.) and its effects on the vibrational properties of wood. J Wood Sci 56:41–46

Brémaud I, Minato K, Langbour P, Thibaut B (2010) Physicochemical indicator of the inter-specific variability in vibration damping of wood. Ann For Sci 67:707

Brémaud I (2012) Acoustical properties of wood in string instruments soundboards and tuned idiophones: biological and cultural diversity. J Acoust Soc Am 131:807–818

Akitsu H, Gril J, Norimoto M (1993) Uniaxial modelling of vibrational properties of chemically modified wood. Mokuzai Gakkaishi 39:258–264

Obataya E, Ono T, Norimoto M (2000) Vibrational properties of wood along the grain. J Mater Sci 35:2993–3001. https://doi.org/10.1023/A:1004782827844

Cave ID (1966) Theory of X-ray measurement of microfibril angle. For Prod J 16:37–42

Matsumoto T (1961) Studies on the dynamic modulus E by transverse vibration. VI. On the dynamic modulus E and the damping of vibrations in compression wood. Mokuzai Gakkaishi 7:90–95 (in Japanese)

Brémaud I, Ruelle J, Thibaut A, Thibaut B (2013) Changes in viscoelastic vibrational properties between compression wood and normal wood: roles of microfibril angle and of lignin. Holzforschung 67:75–85

Timell TE (1986) Compression wood in Gymnosperms. Springer, Berlin

Cabrolier P, Salenson B, Brémaud I (2016) Physical and mechanical properties of Boxwood (Buxus Sepervirens L.)-from the empirical knowledge to measured properties. In: 2nd international symposium wood science and craftsmanship proceedings, pp 69–73

Nakano T (2005) Effects of quenching on relaxation properties of wet wood. J Wood Sci 5:112–117

Furuta Y, Norimoto M, Yano H (1998) Thermal-softening properties of water-swollen Wood V The effects of drying and heating histories. Mokuzai Gakkaishi 44(2):82–88 (In Japanese)

Kudo M, Iida I, Ishimaru Y, Furuta Y (2003) The effects of quenching on the mechanical properties of wet wood. Mokuzai Gakkaishi 49(4):253–259 (in Japanese)

Dlouhá J, Gril J, Clair B, Alméras T (2009) Evidence and modelling of physical aging in green wood. Rheol Acta 48:333–342

Kojiro K, Furuta Y, Ishimaru Y (2008) Influence of histories on dynamic viscoelastic properties and dimensions of water-swollen wood. J Wood Sci 54:95–99

Norimoto M, Tanaka F, Ohogama T, Ikimune R (1986) Specific dynamic Young’s modulus and internal friction of wood in the longitudinal direction. Wood Res Technol Notes 22:53–65 (in Japanese)

Bhuiyan MTR, Hirai N, Sobue N (2000) Changes of crystallinity in wood cellulose by heating treatment under dried and moist conditions. J Wood Sci 46:431–436

Kubojima Y, Okano T, Ohta M (1998) Vibrational properties of Sitka spruce heat-treated in nitrogen gas. J Wood Sci 44:73–77

Čermák P, Rautkari L, Horáček P, Saake B, Rademacher P, Sablík P (2015) Analysis of dimensional stability of thermally modified wood affected by re-wetting cycles. BioResources 10(2):3242–3253

Altgen M, Hofmann T, Militz H (2016) Wood moisture content during the thermal modification process affects the improvement in hygroscopicity of Scots pine sapwood. Wood Sci Technol 50:1181–1195

Endo K, Obataya E, Zeniya N, Mastuo M (2016) Effects of heating humidity on the physical properties of hydrothermally treated spruce wood. Wood Sci Technol 50:1161–1179

Obataya E, Norimoto M (1999) Acoustic properties of a reed (Arundo donax L.) used for vibrating plate of a clarinet. J Acoust Soc Am 106:1106–1110

Abe K, Yamamoto H (2006) Change in mechanical interaction between cellulose microfibril and matrix substance in wood cell wall induced by hygrothermal treatment. J Wood Sci 52:107–110

Goring DAI (1963) Thermal softening of lignin, hemicellulose and cellulose. Pulp Paper Mag Can 64:T517–T527

Salmén L (1984) Viscoelastic properties of in situ lignin under water-saturated conditions. J Mater Sci 19:3090–3096. https://doi.org/10.1007/BF01026988

Furuta Y, Nakajima M, Nakanii E, Ohkoshi M (2010) The effects of lignin and hemicellulose on thermal softening properties of water-swollen wood. Mokuzai Gakkaishi 56:132–138 (In Japanese)

Olsson AM, Salmén L (1992) Viscoelasticity of in situ lignin as affected by structure softwood vs. hardwood. ACS Symp Ser 489:133–143

Olsson AM, Salmén L (1997) The effect of lignin composition on the viscoelastic properties of wood. Nord Pulp Pap J 12:140–144

Barber NF, Meylan BA (1964) The anisotropic shrinkage of wood, a theoretical model. Holzforshung 18:146–156

Yamamoto H (1999) A model of anisotropic swelling and shrinking process of wood. Part 1. Generalization of Barber’s wood fiber model. Wood Sci Technol 33:311–325

Yamamoto H, Almèras T (2007) A mathematical verification of the reinforced-matrix hypothesis using Mori-Tanaka theory. J Wood Sci 53:502–509

Acknowledgements

The authors wish to express their thanks to Associate Professor Eiichi Obataya in University of Tsukuba for his suggestion and discussion of this study. This work was supported by The Foundation of PHOENIX.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors have no conflict of interest directly relevant to the content of this article.

Rights and permissions

About this article

Cite this article

Chen, S., Matsuo-Ueda, M., Yoshida, M. et al. Changes in vibrational properties of compression wood in conifer due to hygrothermal treatment and their relationship with hygrothermal recovery strain. J Mater Sci 54, 3069–3081 (2019). https://doi.org/10.1007/s10853-018-3082-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-3082-x