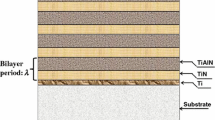

Abstract

A mullite/Si multilayer coating was deposited on a SiC substrate using atmospheric plasma spraying. Mud cracking of the protective surface mullite layer was examined using a high-temperature observation system (HTOS). In-plane surface strain distributions were also measured using the digital image correlation (DIC) method. The experimental results showed that mud cracks nucleated in the mullite layer during heating, primarily due to shrinkage of the mullite during crystallization. The cracking event was detectable by mapping the maximum principal strain distribution. We clearly demonstrated that HTOS and DIC are effective tools for investigating the degradation mechanisms of thick coatings at high temperatures.

Similar content being viewed by others

References

Lee KN, Miller RA, Jacobson NS (1995) New generation of plasma-sprayed mullite coatings on silicon carbide. J Am Ceram Soc 78:705–710. https://doi.org/10.1111/j.1151-2916.1995.tb08236.x

Lee KN, Miller RA (1996) Development and environmental durability of mullite and mullite/YSZ dual layer coatings for SiC and Si3N4 ceramics. Surf Coat Technol 86–87:142–148. https://doi.org/10.1016/s0257-8972(96)03074-5

Lee KN (2000) Key durability issues with mullite-based environmental barrier coatings for Si-based ceramics. J Eng Gas Turbines Power 122:632. https://doi.org/10.1115/1.1287584

Matějíček J, Chráska P, Linke J (2007) Thermal spray coatings for fusion applications—review. J Therm Spray Technol 16:64–83. https://doi.org/10.1007/s11666-006-9007-2

Padture NP (2002) Thermal barrier coatings for gas-turbine engine applications. Science 296:280–284. https://doi.org/10.1126/science.1068609

Davis JR (2004) Handbook of thermal spray technology. https://doi.org/10.1007/bf02647510

Di Girolamo G, Blasi C, Pilloni L, Schioppa M (2009) Microstructural and thermal properties of plasma sprayed mullite coatings. Ceram Int 36:1389–1395. https://doi.org/10.1016/j.ceramint.2010.02.007

Lee KN (2000) Current status of environmental barrier coatings for Si-Based ceramics. Surf Coat Technol 133–134:1–7. https://doi.org/10.1016/S0257-8972(00)00889-6

Lee KN, Fox DS, Eldridge JI et al (2003) Upper temperature limit of environmental barrier coatings based on mullite and bsas. J Am Ceram Soc 86:1299–1306. https://doi.org/10.1111/j.1151-2916.2003.tb03466.x

García E, Miranzo P, Osendi MI (2013) The prospect of Y2SiO5-based materials as protective layer in environmental barrier coatings. J Therm Spray Technol 22:680–689. https://doi.org/10.1007/s11666-013-9917-8

Richards BT, Zhao H, Wadley HNG (2015) Structure, composition, and defect control during plasma spray deposition of ytterbium silicate coatings. J Mater Sci 50:7939–7957. https://doi.org/10.1007/s10853-015-9358-5

Richards BT, Young KA, de Francqueville F et al (2016) Response of ytterbium disilicate-silicon environmental barrier coatings to thermal cycling in water vapor. Acta Metall 106:1–14. https://doi.org/10.1016/j.actamat.2015.12.053

Richards BT, Begley, Wadley HNG (2015) Mechanisms of ytterbium monosilicate/mullite/silicon coating failure during thermal cycling in water vapor. J Am Ceram Soc. https://doi.org/10.1111/jace.13792

Guo HB, Vaßen R, Stöver D (2005) Thermophysical properties and thermal cycling behavior of plasma sprayed thick thermal barrier coatings. Surf Coat Technol 192:48–56. https://doi.org/10.1016/j.surfcoat.2004.02.004

Song M, Guo H, Abbas M, Gong S (2013) Thermal deformation of Y2O3 partially stabilized ZrO2 coatings by digital image correlation method. Surf Coat Technol 216:1–7. https://doi.org/10.1016/j.surfcoat.2012.09.022

Dong Y, Kakisawa H, Kagawa Y (2013) Optical system for microscopic observation and strain measurement at high temperature. Meas Sci Technol 25:025002–025010. https://doi.org/10.1088/0957-0233/25/2/025002

Dong Y, Kakisawa H, Kagawa Y (2015) Development of microscale pattern for digital image correlation up to 1400 C. Opt Lasers Eng 68:7–15. https://doi.org/10.1016/j.optlaseng.2014.12.003

Arai Y, Inoue R, Tanaka H et al (2016) In-situ observation of oxidation behavior in ZrB2-SiC-ZrC ternary composites up to 1500 °C using high-temperature observation system. J Ceram Soc Jpn 124:890–897. https://doi.org/10.2109/jcersj2.16043

Novak MD, Zok FW (2011) High-temperature materials testing with full-field strain measurement: experimental design and practice. Rev Sci Instrum 82:115101–115107. https://doi.org/10.1063/1.3657835

Takamori T, Roy R (1973) Rapid crystallization of SiO2-Al2O3 glasses. J Am Ceram Soc 56:639–644. https://doi.org/10.1111/j.1151-2916.1973.tb12442.x

Richards BT, Wadley HNG (2014) Plasma spray deposition of tri-layer environmental barrier coatings. J Eur Ceram Soc 34:3069–3083. https://doi.org/10.1016/j.jeurceramsoc.2014.04.027

Spitsberg I, Steibel J (2004) Thermal and environmental barrier coatings for SiC/SiC CMCs in aircraft engine applications. Int J Appl Ceram Technol 1:291–301. https://doi.org/10.1111/j.1744-7402.2004.tb00181.x

Hsueh C-H (2002) Thermal stresses in elastic multilayer systems. Thin Solid Films 418:182–188. https://doi.org/10.1016/S0040-6090(02)00699-5

Inoue R, Chikamoto K, Kogo Y, Kakisawa H (2017) Effect of heat exposure on the microstructures and mechanical properties of 3Al2O3 2SiO2/Si/SiC coating system. Wiley-Blackwell, Hoboken, NJ, pp 443–450

Cojocaru CV, Krueger S, Moreau C, Lima RS (2010) Elastic modulus evolution and behavior of Si/Mullite/BSAS-based environmental barrier coatings exposed to high temperature in water vapor environment. J Therm Spray Technol 20:92–99. https://doi.org/10.1007/s11666-010-9599-4

Okada Y, Tokumaru Y (1984) Precise determination of lattice parameter and thermal expansion coefficient of silicon between 300 and 1500 K. J Appl Phys 56:314–320. https://doi.org/10.1063/1.333965

Schall JD, Gao G, Harrison JA (2008) Elastic constants of silicon materials calculated as a function of temperature using a parametrization of the second-generation reactive empirical bond-order potential. Phys Rev B 77:115209. https://doi.org/10.1103/PhysRevB.77.115209

Munro RG (1997) Material properties of a sintered α-sic. J Phys Chem Ref Data 26:1195–1203. https://doi.org/10.1063/1.556000

Acknowledgements

This research was partially supported by a Grant-in-Aid for Young Scientists (B) by the Ministry of Education, Culture, Sports, Science and Technology (MEXT, Japan), No. 17K18144.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Inoue, R., Arai, Y. & Kakisawa, H. In situ observation and strain distribution measurements of atmospheric plasma-sprayed mullite and Si multilayered coatings on SiC substrates. J Mater Sci 54, 2824–2835 (2019). https://doi.org/10.1007/s10853-018-3080-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-3080-z