Abstract

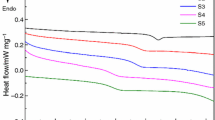

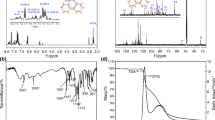

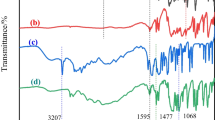

In this study, a novel halogen-free flame retarded form-stable phase change material (PCM) was designed and prepared, selecting paraffin as the thermal-energy storage material and epoxy resin (EP) as the supporting material; furthermore, a novel flame retardant curing agent PEPA–TMA (2,6,7-trioxa-1-phosphabicyclo-[2.2.2]-octane-4-methanol reacted with trimellitic anhydride) and melamine cyanurate were combined into the energy-storing material to obtain the flame retarded PCM. Thermal performances of the PCM were investigated through differential scanning calorimeter, the data suggested that the PCM had relatively high latent heat, and values normalized to the amount of paraffin were lower than the theoretical values. The thermogravimetric analysis displayed that the intumescent flame retardant (IFR) could improve the charring of the PCM, and the PCM had passed a UL 94 V-0 test when the IFR loading reached 24 wt%. The cone calorimeter results further proved that the PCM had better flame retardancy. The morphology of the composites was observed by scanning electron microscopy, and the images showed that the paraffin could be dispersed uniformly in the materials, which formed a three-dimensional network by EP.

Similar content being viewed by others

References

Zhang P, Song L, Lu H, Wang J, Hu Y (2010) The influence of expanded graphite on thermal properties for paraffin/high density polyethylene/chlorinated paraffin/antimony trioxide as a flame retardant phase change material. Energy Convers Manag 51:2733–2737

Reyes A, Henriquez-Vargas L, Aravena R, Sepulveda F (2015) Experimental analysis, modeling and simulation of a solar energy accumulator with paraffin wax as PCM. Energy Convers Manag 105:189–196

Sun X, Zhang Q, Medina MA, Lee KO, Liao S (2016) Parameter design for a phase change material board installed on the inner surface of building exterior envelopes for cooling in China. Energy Convers Manag 120:100–108

Jiang Z, Ouyang T, Yang Y, Chen L, Fan X, Chen Y, Li W, Fei Y (2018) Thermal conductivity enhancement of phase change materials with form-stable carbon bonded carbon fiber network. Mater Des 143:177–184

Li L, Wang G, Guo C (2016) Influence of intumescent flame retardant on thermal and flame retardancy of eutectic mixed paraffin/polypropylene form-stable phase change materials. Appl Energy 162:428–434

Li W-W, Cheng W-L, Xie B, Liu N, Zhang L-S (2017) Thermal sensitive flexible phase change materials with high thermal conductivity for thermal energy storage. Energy Convers Manag 149:1–12

Mochane M, Luyt A (2015) The effect of expanded graphite on the flammability and thermal conductivity properties of phase change material based on PP/wax blends. Polym Bull 72:2263–2283

Guo X, Cao J, Peng Y, Liu R (2016) Incorporation of microencapsulated dodecanol into wood flour/high-density polyethylene composite as a phase change material for thermal energy storage. Mater Des 89:1325–1334

Qiu X, Lu L, Chen Z (2015) Preparation and characterization of flame retardant phase change materials by microencapsulated paraffin and diethyl ethylphosphonate with poly (methacrylic acid-co-ethyl methacrylate) shell. J Appl Polym Sci 132:41880

Wang J, Wang Y, Yang R (2015) Flame retardance property of shape-stabilized phase change materials. Sol Energy Mater Sol Cells 140:439–445

Zhang P, Hu Y, Song L, Ni J, Xing W, Wang J (2010) Effect of expanded graphite on properties of high-density polyethylene/paraffin composite with intumescent flame retardant as a shape-stabilized phase change material. Sol Energy Mater Sol Cells 94:360–365

Sarı A (2016) Thermal energy storage characteristics of bentonite-based composite PCMs with enhanced thermal conductivity as novel thermal storage building materials. Energy Convers Manag 117:132–141

Mehrali M, Latibari ST, Mehrali M, Mahlia TMI, Metselaar HSC (2013) Preparation and properties of highly conductive palmitic acid/graphene oxide composites as thermal energy storage materials. Energy 58:628–634

Chen C, Zhang H, Gao X, Xu T, Fang Y, Zhang Z (2016) Numerical and experimental investigation on latent thermal energy storage system with spiral coil tube and paraffin/expanded graphite composite PCM. Energy Convers Manag 126:889–897

Inaba H, Tu P (1997) Evaluation of thermophysical characteristics on shape-stabilized paraffin as a solid–liquid phase change material. Heat Mass Transf 32:307–312

Fang Y, Kang H, Wang W, Liu H, Gao X (2010) Study on polyethylene glycol/epoxy resin composite as a form-stable phase change material. Energy Convers Manag 51:2757–2761

Krupa I, Miková G, Luyt A (2007) Phase change materials based on low-density polyethylene/paraffin wax blends. Eur Polym J 43:4695–4705

Trigui A, Karkri M, Krupa I (2014) Thermal conductivity and latent heat thermal energy storage properties of LDPE/wax as a shape-stabilized composite phase change material. Energy Convers Manag 77:586–596

Hong Y, Xin-shi G (2000) Preparation of polyethylene–paraffin compound as a form-stable solid-liquid phase change material. Sol Energy Mater Sol Cells 64:37–44

Sarı A (2004) Form-stable paraffin/high density polyethylene composites as solid–liquid phase change material for thermal energy storage: preparation and thermal properties. Energy Convers Manag 45:2033–2042

Zhao W, Liu J, Zhang Y, Ban D (2015) Simple green synthesis of solid polymeric bisphenol A bis (diphenyl phosphate) and its flame retardancy in epoxy resins. RSC Adv 5:80415–80423

Liang B, Cao J, Hong X, Wang C (2013) Synthesis and properties of a novel phosphorous-containing flame-retardant hardener for epoxy resin. J Appl Polym Sci 128:2759–2765

Zhao W, Liu J, Peng H, Liao J, Wang X (2015) Synthesis of a novel PEPA-substituted polyphosphoramide with high char residues and its performance as an intumescent flame retardant for epoxy resins. Polym Degrad Stab 118:120–129

Luyt A, Krupa I (2009) Phase change materials formed by uv curable epoxy matrix and Fischer–Tropsch paraffin wax. Energy Convers Manag 50:57–61

Zhang P, Song L, Lu H, Wang J, Hu Y (2010) The thermal property and flame retardant mechanism of intumescent flame retardant paraffin system with metal. Ind Eng Chem Res 49:6003–6009

Ferdosian F, Yuan Z, Anderson M, Xu CC (2016) Thermal performance and thermal decomposition kinetics of lignin-based epoxy resins. J Anal Appl Pyrol 119:124–132

Kuznik F, David D, Johannes K, Roux J-J (2011) A review on phase change materials integrated in building walls. Renew Sustain Energy Rev 15:379–391

Xu L, Wang W, Yu D (2017) Durable flame retardant finishing of cotton fabrics with halogen-free organophosphonate by UV photoinitiated thiol-ene click chemistry. Carbohydr Polym 172:275–283

Yu W, Huang T, Lei W (2014) Synthesis, application of a novel halogen-free intumescent flame retardant agent for poplar wood veneer. Adv Mater Res 1004:1022–1025

Gaan S, Sun G, Hutches K, Engelhard MH (2008) Effect of nitrogen additives on flame retardant action of tributyl phosphate: phosphorus–nitrogen synergism. Polym Degrad Stab 93:99

Zuo J, Su Y, Liu S, Sheng Q (2011) Preparation and properties of FR-PP with phosphorus-containing intumescent flame retardant. J Polym Res 18:1125–1129

Nie S, Hu Y, Song L, He Q, Yang D, Chen H (2008) Synergistic effect between a char forming agent (CFA) and microencapsulated ammonium polyphosphate on the thermal and flame retardant properties of polypropylene. Polym Adv Technol 19:1077–1083

Ma T, Guo C (2017) Synergistic effect between melamine cyanurate and a novel flame retardant curing agent containing a caged bicyclic phosphate on flame retardancy and thermal behavior of epoxy resins. J Anal Appl Pyrol 124:239–246

Cai Y, Wei Q, Huang F, Lin S, Chen F, Gao W (2009) Thermal stability, latent heat and flame retardant properties of the thermal energy storage phase change materials based on paraffin/high density polyethylene composites. Renew Energy 34:2117–2123

Qian Y, Wei P, Jiang P, Liu J (2012) Preparation of halogen-free flame retardant hybrid paraffin composites as thermal energy storage materials by in situ sol–gel process. Sol Energy Mater Sol Cells 107:13–19

Cai Y, Wei Q, Huang F, Gao W (2008) Preparation and properties studies of halogen-free flame retardant form-stable phase change materials based on paraffin/high density polyethylene composites. Appl Energy 85:765–775

Babrauskas V (1982) Development of cone calorimeter-a bench scale, rate of heat release based on oxygen consumption, NBS-IR 82-2611. US National Bureau of Standards, Gaithersburg

Wang Z, Qu B, Fan W, Huang P (2001) Combustion characteristics of halogen-free flame-retarded polyethylene containing magnesium hydroxide and some synergists. J Appl Polym Sci 81:206–214

Xu M, Chen Y, Qian L, Wang J, Tang S (2014) Component ratio effects of hyperbranched triazine compound and ammonium polyphosphate in flame-retardant polypropylene composites. J Appl Polym Sci 21:41006

Yan H, Zhang J, Zhang M, Du X, Ma S, Xu B (2016) Synergistic flame-retardant effect of IFR and PPO in improving flame retardancy of polystyrene. Adv Polym Technol 35:208–214

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (31670516 and 31570572).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Ma, T., Li, L., Wang, Q. et al. High-performance flame retarded paraffin/epoxy resin form-stable phase change material. J Mater Sci 54, 875–885 (2019). https://doi.org/10.1007/s10853-018-2846-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2846-7