Abstract

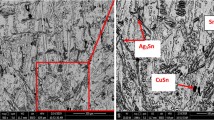

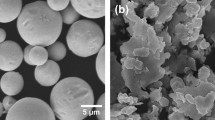

Solder paste of Ag and SAC0307 (Sn-0.3 wt%Ag-0.7 wt%Cu) mixed powders was fabricated and utilized as the interlayer to achieve a Cu/SAC0307–Ag/Cu transient liquid phase (TLP) sintered joint. The microstructural evolution and mechanical reliability of the joint during thermal aging at 350 °C were systematically studied. A serial transition of Ag–Sn phase occurred from Ag3Sn into Ag4Sn and eventually into Ag–Sn solid solution (Ag) until 15 days, accompanied with the formation of Cu3Sn network inside the Ag–Sn phase layer. It was because that the Cu atoms diffused from the substrate into the Ag–Sn phase layer and then reacted with Ag–Sn phase, including two processes: 4Ag3Sn + 3Cu → 3Ag4Sn + Cu3Sn and Ag4Sn + 3Cu → 4Ag + Cu3Sn. The shear strength of the aged joint decreased from 75 to 60 MPa after 15 days due to the transition of Ag–Sn phases and the formation of contraction voids, and then it remained stable. The comparisons of hardness and elasticity modulus between the three Ag–Sn phases were both as follows: Ag3Sn > Ag4Sn > Ag–Sn solid solution. Thus, the excellent reliability of the TLP sintered joint with SAC0307–Ag powders was experimentally verified.

Similar content being viewed by others

References

Manikam VR, Cheong KY (2011) Die attach materials for high temperature applications: a review. IEEE Trans Compon Packag Manuf Technol 1:457–478

Möller E, Bajwa AA, Rastjagaev E, Wilde J (2014) Comparison of new die-attachment technologies for power electronic assemblies. In: IEEE Transactions on Electronic Components and Technology, pp 1707–1713

Khazaka R, Mendizabal L, Henry D, Hanna R (2015) Survey of high-temperature reliability of power electronics packaging components. IEEE Trans Power Electron 30:2456–2464

Yoon SW, Glover MD, Mantooth HA, Shiozaki K (2013) Reliable and repeatable bonding technology for high temperature automotive power modules for electrified vehicles. J Micromec Microeng 23:015–017

Yoon SW, Glover MD, Shiozaki K (2012) Nickel-tin transient liquid phase bonding toward high-temperature operational power electronics in electrified vehicles. IEEE Trans Power Electron 28:2448–2456

Neudeck PG, Okojie RS, Chen LY (2002) High-temperature electronics—a role for wide bandgap semiconductors? Proc IEEE 90:1065–1076

Lee JB, Hwang HY, Rhee MW (2015) Reliability investigation of Cu/In TLP bonding. J Electron Mater 44:435–441

Hamada K, Nagao M, Ajioka M, Kawai F (2015) SiC-emerging power device technology for next-generation electrically powered environmentally friendly vehicles. IEEE Trans Electron Devices 62:278–285

Chidambaram V, Hattel J, Hald J (2010) Design of lead-free candidate alloys for high-temperature soldering based on the Au–Sn system. Mater Des 31:4638–4645

Fan J, Tan CS (2012) Low temperature wafer-level metal thermo-compression bonding technology for 3D integration. Metall 4:71–94

Yang C, Li X, Lu G, Mei Y (2016) Enhanced pressureless bonding by tin doped silver paste at low sintering temperature. Mater Sci Eng, A 660:71–76

Bosco NS, Zok FW (2005) Strength of joints produced by transient liquid phase bonding in the Cu–Sn system. Acta Mater 53:2019–2027

Shao H, Wu A, Bao Y, Zhao Y, Liu L, Zou G (2018) Novel transient liquid phase bonding through capillary action for high-temperature power devices packaging. Mater Sci Eng A 724:231–238

Cook GO, Sorensen CD (2011) Overview of transient liquid phase and partial transient liquid phase bonding. J Mater Sci 46:5305–5323. https://doi.org/10.1007/s10853-011-5561-1

Li JF, Agyakwa PA, Johnson CM (2010) Kinetics of Ag3Sn growth in Ag–Sn–Ag system during transient liquid phase soldering process. Acta Mater 58:3429–3443

Li JF, Agyakwa PA, Johnson CM (2011) Interfacial reaction in Cu/Sn/Cu system during the transient liquid phase soldering process. Acta Mater 59:1198–1211

Shao H, Wu A, Bao Y, Zhao Y, Liu L, Zou G (2017) Elimination of pores in Ag–Sn TLP bonds by the introduction of dissimilar intermetallic phases. J Mater Sci 52:3508–3519. https://doi.org/10.1007/s10853-016-0645-6

Liu J, Kumar P, Dutta I, Raj R, Sidhu R, Renavikar M (2011) Liquid phase sintered Cu–In composite solders for thermal interface material and interconnect applications. J Mater Sci 46:7012–7025. https://doi.org/10.1007/s10853-011-5670-x

Dong H, Li Z, Song X, Zhao H, Tian H, Liu J, Yan J (2017) Grain morphology evolution and mechanical strength change of intermetallic joints formed in Ni/Sn/Cu system with variety of transient liquid phase soldering temperatures. Mater Sci Eng A 705:360–365

Hang C, Tian Y, Zhang R (2013) Phase transformation and grain orientation of Cu–Sn intermetallic compounds during low temperature bonding process. J Mater Sci: Mater Electron 24:3905–3913

Liu B, Tian Y, Wang C, An R, Liu Y (2016) Extremely fast formation of Cu–Sn intermetallic compounds in Cu/Sn/Cu system via a micro-resistance spot welding process. J Alloy Compd 687:667–673

Li Z, Li M, Xiao Y, Wang C (2014) Ultrarapid formation of homogeneous Cu6Sn5 and Cu3Sn intermetallic compound joints at room temperature using ultrasonic waves. Ultrason Sonochem 21:924–929

Shao H, Wu A, Bao Y, Zhao Y, Liu L, Zou G (2017) Rapid Ag/Sn/Ag transient liquid phase bonding for high-temperature power devices packaging by the assistance of ultrasound. Ultrason Sonochem 37:561–570

Greve H, Chen LY, Fox I (2013) Transient liquid phase sintered attach for power electronics. IEEE Trans Electron Compon Technol Conf 63:435–440

Greve H, Moeini SA, Mccluskey FP (2014) Reliability of paste based transient liquid phase sintered interconnects. IEEE Trans Electron Compon Technol Conf 64:1314–1320

Liu X, He S, Nishikawa H (2016) Thermally stable Cu3Sn/Cu composite joint for high-temperature power device. Scr Mater 110:101–104

Liu X, He S, Nishikawa H (2016) Low temperature solid-state bonding using Sn-coated Cu particles for high temperature die attach. J Alloy Compd 695:2165–2172

Tollefsen TA, Larsson A, Løvvik OM (2013) High temperature interconnect and die Attach technology: Au–Sn SLID bonding. IEEE Trans Compon Packag Manuf Technol 3:904–914

Mustain HA, Brown WD, Ang SS (2010) Transient liquid phase die attach for high-temperature silicon carbide power devices. IEEE Trans Compon Packag Manuf Technol 33:563–570

Ghosh G (2004) Elastic properties, hardness and indentation fracture toughness of intermetallics relevant to electronic packaging. J Mater Res 19:1439–1454

Paul AA (2004) The Kirkendall effect in solid state diffusion. PhD Dissertation, Technische Universiteit Eindhoven

Yu J, Kim JY (2008) Effects of residual S on Kirkendall void formation at Cu/Sn–3.5Ag solder joints. Acta Mater 56:5514–5523

Okamoto H (2010) Desk edition: phase diagram for binary alloys, 2nd edn. ASM International, Ohio, p 269

Bao Y, Wu A, Shao H, Zhao Y, Zou G (2018) Effects of powders on microstructures and mechanical properties for Sn–Ag transient liquid phase bonding in air. J Mater Sci: Mater Electron 29:1–12

Acknowledgements

This research is financially supported by the National Science Foundation of China under Grant No. 51375260, which is entitled “Technology and Mechanism of Low Temperature Transient Liquid Phase Bonding”.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

10853_2018_2809_MOESM1_ESM.docx

The online version of this article contains supplementary material, which is available to authorized users. (DOCX 50 kb)

Rights and permissions

About this article

Cite this article

Bao, Y., Wu, A., Shao, H. et al. Microstructural evolution and mechanical reliability of transient liquid phase sintered joint during thermal aging. J Mater Sci 54, 765–776 (2019). https://doi.org/10.1007/s10853-018-2809-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2809-z