Abstract

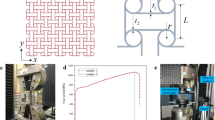

The purpose of this study is to explore a new type of structure design and injecting material selection of the composite sandwich bulletproof system. A re-entrant hexagonal honeycomb with the negative Poisson’s ratio effect was designed. Thermoplastic polyurethanes (TPU), polypropylene (PP) and polycarbonate (PC) were chosen to inject into the re-entrant honeycomb structure by injection molding to form the composite sandwich layers. The total bulletproof system was later constructed with the boron carbide ceramic plates and aluminum alloy plates. The mechanical behaviors and energy absorption characteristics of different composite sandwich layers were investigated by quasi-static and dynamic compression tests. The dynamic responses of different structured layers were analyzed via numerical simulations in ANSYS/LS-DYNA, which employed 7.62 mm projectiles. The results indicated that the injection-molded composite sandwich layer shows excellent compressive strength and energy absorption capacity. The bulletproof performance of the injection-molded system has been greatly improved comparing with the non-injected molded system. Compared with TPU and PP, the composite injected with PC presents optimal penetration resistance.

Similar content being viewed by others

References

Naik NK, Kumar S, Ratnaveer D, Joshi M, Akella K (2013) An energy-based model for ballistic impact analysis of ceramic-composite armors. Int J Damage Mech 22:145. https://doi.org/10.1177/1056789511435346

Kaboglu C, Mohagheghian I, Zhou J et al (2017) High-velocity impact deformation and perforation of fibre metal laminates. J Mater Sci 53:4209. https://doi.org/10.1007/s10853-017-1871-2

Jackson M, Shukla A (2011) Performance of sandwich composites subjected to sequential impact and air blast loading. Compos B Eng 42:155. https://doi.org/10.1016/j.compositesb.2010.09.005

Liu X, Li M, Li X et al (2018) Ballistic performance of UHMWPE fabrics/EAMS hybrid panel. J Mater Sci 53:7357. https://doi.org/10.1007/s10853-018-2055-4

Feli S, Namdari Pour MH (2012) An analytical model for composite sandwich panels with honeycomb core subjected to high-velocity impact. Compos B Eng 43:2439. https://doi.org/10.1016/j.compositesb.2011.11.028

Wilkins ML (1978) Mechanics of penetration and perforation. Int J Eng Sci 16:793. https://doi.org/10.1016/0020-7225(78)90066-6

Rizov V, Mladensky A (2008) Mechanical behavior of composite sandwich structures subjected to low velocity impact—experimental testing and finite element modeling. Polym Polym Compos 16:233

Bartus SD, Vaidya UK (2007) A review: impact damage of composite materials. J Adv Mater 39:3

Tan P (2014) Numerical simulation of the ballistic protection performance of a laminated armor system with pre-existing debonding/delamination. Compos B 59:50

Übeyli M, Yıldırım RO, Ögel B (2008) Investigation on the ballistic behavior of Al2O3/Al2024 laminated composites. J Mater Process Technol 196:356

Zhang Z, Shen J, Zhong W, Sun Z (2002) A dynamic model of ceramic/fibre-reinforced plastic hybrid composites under projectile striking. Proc Inst Mech Eng Part G J Aerosp Eng 216:325

Übeyli M, Yıldırım RO, Ögel B (2007) On the comparison of the ballistic performance of steel and laminated composite armors. Mater Des 28:1257

Grujicic M, Bell WC, Pandurangan B (2012) Design and material selection guidelines and strategies for transparent armor systems. Mater Des 34:808

Wang Q, Chen Z, Chen Z (2013) Design and characteristics of hybrid composite armor subjected to projectile impact. Mater Des 46:634

Signetti S, Pugno NM (2014) Evidence of optimal interfaces in bio-inspired ceramic-composite panels for superior ballistic protection. J Eur Ceram Soc 34:2823

Krishnan K, Sockalingam S, Bansal S, Rajan SD (2010) Numerical simulation of ceramic composite armor subjected to ballistic impact. Compos B Eng 41:583

Lee HS, Hong SH, Lee JR, Kim YK (2002) Mechanical behavior and failure process during compressive and shear deformation of honeycomb composite at elevated temperatures. J Mater Sci 37:1265. https://doi.org/10.1023/a:1014344228141

Ju J, Summers JD (2011) Compliant hexagonal periodic lattice structures having both high shear strength and high shear strain. Mater Des 32:512

Hönig A, Stronge WJ (2002) In-plane dynamic crushing of honeycomb. Part I: crush band initiation and wave trapping. Int J Mech Sci 44:1665

Dogan A, Arıkan V (2017) Low-velocity impact response of E-glass reinforced thermoset and thermoplastic based sandwich composites. Compos B Eng 127:63

Tranter JB, Refalo P, Rochman A, Tranter JB, Refalo P, Rochman A (2017) Towards sustainable injection molding of ABS plastic products. J Manuf Process 29:399

Li X, Gong N, Yang C, Zeng S, Fu S, Zhang K (2018) Aluminum/polypropylene composites produced through injection molding. J Mater Process Technol 255:635

Alderson A, Alderson KL (2000) Auxetic materials. Proc Inst Mech Eng Part G J Aerosp Eng 221:565

Hou J, Li D, Dong L (2018) Mechanical behaviors of hierarchical cellular structures with negative Poisson’s ratio. J Mater Sci. https://doi.org/10.1007/s10853-018-2298-0

Yang W, Li ZM, Shi W, Xie BH, Yang MB (2004) Review on auxetic materials. J Mater Sci 39:3269. https://doi.org/10.1023/B%3AJMSC.0000026928.93231.e0

Alderson A, Alderson A (1999) A triumph of lateral thought. Chem Ind 318:384

Scarpa F, Blain S, Lew T, Perrott D, Ruzzene M, Yates JR (2007) Elastic buckling of hexagonal chiral cell honeycombs. Compos A 38:280

Yang L, Cormier D, West H, Harrysson O, Knowlson K (2012) Non-stochastic Ti–6Al–4 V foam structures with negative Poisson’s ratio. Mater Sci Eng, A 558:579

Hong C, Gu D, Dai D et al (2015) Laser additive manufacturing of ultrafine TiC particle reinforced Inconel 625 based composite parts: tailored microstructures and enhanced performance. Mater Sci Eng, A 635:118

Domnich V, Reynaud S, Haber RA, Chhowalla M (2011) Boron carbide: structure, properties, and stability under stress. J Am Ceram Soc 94:3605

Guden M, Hall IW (1998) Quasi-static and dynamic compression behaviour of an FPTM alumina-reinforced aluminium metal matrix composite. J Mater Sci 33:3285. https://doi.org/10.1023/a:1013272910939

Feng J, Wang E, Chen X, Ding H (2017) Energy dissipation rate: an indicator of coal deformation and failure under static and dynamic compressive loads. Int J Min Sci Technol. https://doi.org/10.1016/j.ijmst.2017.11.006

Chen M, Jing H et al (2017) Fracture evolution characteristics of sandstone containing double fissures and a single circular hole under uniaxial compression. Int J Min Sci Technol 27:499

China, MOPS (2010) Ballistic resistance of body armor. GA 141-2010

Zhang Q, Zhou G, Qian X, Yuan M, Sun Y, Wang D (2018) Diffuse pollution characteristics of respirable dust in fully-mechanized mining face under various velocities based on CFD investigation. J Clean Prod 184:239. https://doi.org/10.1016/j.jclepro.2018.02.230

Bürger D, Faria ARD, Almeida SFMD, Melo FCLD, Donadon MV (2012) Ballistic impact simulation of an armour-piercing projectile on hybrid ceramic/fiber reinforced composite armours. Int J Impact Eng 43:63

Miltz J, Gruenbaum G (1981) Evaluation of cushion properties of plastic foams compressive measurements. Polym Eng Sci 21:1010

Acknowledgements

We would like to thank 135 National Key Research And Development Plan (Grant number 2016YFC0802800) and the Youth Fund Of National Natural Science Foundation Project (Grant number 51606011) for the support of this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Rights and permissions

About this article

Cite this article

Zhao, L., Qian, X., Sun, Y. et al. Ballistic behaviors of injection-molded honeycomb composite. J Mater Sci 53, 14287–14298 (2018). https://doi.org/10.1007/s10853-018-2611-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2611-y