Abstract

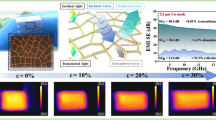

The mechanical stability of transparent and stretchable electrode materials is essential for their application in stretchable electronic devices. In this work, single-walled carbon nanotube (SWCNT)–silver nanowire (Ag NW) composite films were developed as electrode materials to improve the thermal stability and anti-electromigration characteristics of transparent stretchable film heaters. By adjusting the mixing ratio of SWCNT–Ag NW suspensions, the mechanical and anti-electromigration properties of SWCNT–Ag NW composite films were systematically investigated. Compared to pristine Ag NW film, the 75:1 SWCNT–Ag NW composite film exhibited an excellent thermal stability, improved anti-electromigration properties, and low sheet resistance of 62.3 Ω/sq with an optical transmittance of 83.4%. Moreover, the same composite film prepared on VHB substrate showed only 23.2% increase in the relative sheet resistance after 1000 times of stretching cycles under the tensile stress. Furthermore, the stretchable film heater with 75:1 SWCNT–Ag NW composite electrode exhibited an improved thermal and mechanical stability even after being exposed to 1000 stretching cycles with a peak strain of 200%.

Similar content being viewed by others

References

Service RF (2003) Technology. Electronic textiles charge ahead. Science 301:909–911

Yamada T, Hayamizu Y, Yamamoto Y, Yomogida Y, Izadi-Najafabadi A, Futaba DN, Hata K (2011) A stretchable carbon nanotube strain sensor for human-motion detection. Nat Nanotechnol 6(5):296–301

Xu S, Zhang Y, Cho J, Lee J, Huang X, Jia L, Fan JA, Su Y, Su J, Zhang H, Cheng H, Lu B, Yu C, Chuang C, Kim T, Song T, Shigeta K, Kang S, Dagdeviren C, Petrov I, Braun PV, Huang Y, Paik U, Rogers J (2013) A stretchable batteries with self-similar serpentine interconnects and integrated wireless recharging systems. Nat Commun 4:1543–1548

Wang C, Zheng W, Yue Z, Too CO, Wallace GG (2011) Buckled stretchable polypyrrole electrodes for battery applications. Adv Mater 23:3580–3584

Aliev AE, Oh J, Kozlov ME, Kuznetsov AA, Fang S, Fonseca AF, Ovalle R, Lima MD, Haque MH, Gartstein YN, Zhang M, Zakhidov AA, Baughman RH (2009) Giant-stroke, superelastic carbon nanotube aerogel muscles. Science 323:1575–1579

Liang J, Li L, Niu X, Yu Z, Pei Q (2013) Elastomeric polymer light-emitting devices and displays. Nat Photonics 7:817–824

Larson C, Peele B, Li S, Robinson S, Totaro M, Beccai L, Mazzolai B, Shepherd R (2016) Highly stretchable electroluminescent skin for optical signaling and tactile sensing. Science 351:1071–1074

Tasawar H, Sumaira Q, Maria I, Faris A, Ahmed A (2016) Partial slip effect in flow of magnetite-Fe3O4 nanoparticles between rotating stretchable disks. J Magn Magn Mater 413:39–48

Ming Q, Qin S, Guanglei W, Bohan Z, Zhengdong W, Hongjing W (2017) Zinc ferrite composite materials wuth controllable morphology and its applications. Mater Sci Eng B 224:125–138

Shaohua Q, Yinkai Y, Kejun L, Peiyu L, Chenhui Z, Liuding W, Tingting X, Zhengdong W, Hongjing W (2018) Easy hydrothermal synthesis of multi-shelled La2O3 hollow spheres for lithium-ion batteries. J Mater Sci Mater Electron 29:1232

Kamalisarvestani M, Saidur R, Mekhilef S, Javadi FS (2013) Performance, materials and coating technologies of thermochromic thin films on smart windows. Renew Sustain Energy Rev 26:353–364

Jo HS, An S, Lee JG, Park HG, Al-Deyab SS, Yarin AL, Yoon SS (2017) Highly flexible, stretchable, patternable, transparent copper fiber heater on a complex 3D surface. NPG Asia Mater 9(2):e347

Ke S, Chen C, Fu N, Zhou H, Ye M, Lin P, Yuan W, Zeng X, Chen L, Huang H (2016) Transparent indium tin oxide electrodes on muscovite mica for high-temperature-processed flexible optoelectronic devices. ACS Appl Mater Interfaces 8:28406–28411

Ho X, Wei J (2013) Films of carbon nanomaterials for transparent conductors. Materials 6:2155–2181

Angmo D, Larsen-Olsen TT, Jørgensen M, Søndergaard RR, Krebs FC (2013) Roll-to-roll inkjet printing and photonic sintering of electrodes for ITO free polymer solar cell modules and facile product integration. Adv Energy Mater 3(2):172–175

Jung D, Kim D, Lee KH, Overzet LJ, Lee GS (2013) Transparent film heaters using multi-walled carbon nanotube sheets. Sens Actuators A 199:176–180

Sui D, Huang Y, Huang L, Liang J, Ma Y, Chen Y (2011) Flexible and transparent electrothermal film heaters based on graphene materials. Small 7:3186–3192

Liu P, Liu L, Jiang K, Fan S (2011) Carbon-nanotube-film microheater on a polyethylene terephthalate substrate and its application in thermochromic displays. Small 7:732–736

Kim T, Kim YW, Lee HS, Kim H, Yang WS, Suh KS (2013) Uniformly interconnected silver-nanowire networks for transparent film heaters. Adv Funct Mater 23:1250–1255

Khan A, Lee S, Jang T, Xiong Z, Zhang C, Tang JL, Guo J, Li WD (2016) High-performance flexible tansparent electrode with an embedded metal mesh fabricated by cost-effective solution process. Small 12:3021–3030

Duzyer S, Sinha-ray S, Sinha-ray S, Yarin AL (2017) Transparent conducting electrodes from conducting polymer nanofibers and their application as thin-film heaters. Macromol Mater Eng 302:1700188

Ko Y, Song SK, Kim NH, Chang ST (2016) Highly transparent and stretchable conductors based on a directional arrangement of silver nanowires by a microliter-scale solution process. Langmuir 32:366–373

Wang J, Yan C, Kang W, Lee PS (2014) High-efficiency transfer of percolating nanowire films for stretchable and transparent photodetectors. Nanoscale 6:10734–10739

Lagrange M, Sannicolo T, Lohan BG, Khan A, Anikin M, Jiménez C, Bruckert F, Bréchet Y, Bellet D (2017) Understanding the mechanisms leading to failure in metallic nanowire-based transparent heaters, and solution for stability enhancement. Nanotechnology 28:55709

Khaligh HH, Goldthorpe IA (2013) Failure of silver nanowire transparent electrodes under current flow. Nanoscale Res Lett 8:235

Woo JY, Kim KK, Lee J, Kim JT, Han CS (2014) Highly conductive and stretchable Ag nanowire/carbon nanotube hybrid conductors. Nanotechnology 25:285203

Stapleton AJ, Yambem SD, Johns AH, Afre RA, Ellis AV, Shapter JG, Andersson GG, Quinton JS, Burn PL, Meredith P, Lewis DA (2015) Planar silver nanowire, carbon nanotube and PEDOT:PSS nanocomposite transparent electrodes. Sci Technol Adv Mater 16:25002

Jing M, Han C, Li M, Shen X (2014) High performance of carbon nanotubes/silver nanowires-PET hybrid flexible transparent conductive films via facile pressing-transfer technique. Nanoscale Res Lett 9:588

Ruoff RS, Qian D, Liu WK (2003) Mechanical properties of carbon nanotubes: theoretical predictions and experimental measurements. C R Phys 4:993–1008

McCreery RL (2008) Advanced carbon electrode materials for molecular electrochemistry. Chem Rev 108:2646–2687

Dumitrescu I, Unwin PR, Macpherson JV (2009) Electrochemistry at carbon nanotubes: perspective and issues. Chem Commun 45:6886–6901

Lee P, Lee J, Lee H, Yeo J, Hong S, Nam KH, Lee D, Lee SS, Ko SH (2012) Highly stretchable and highly conductive metal electrode by very long metal nanowire percolation network. Adv Mater 24:3326–3332

Naumov AV, Ghosh S, Tsyboulski DA, Bachilo SM, Weisman RB (2011) Analyzing absorption backgrounds in single-walled carbon nanotube spectra. ACS Nano 5:1639–1648

Tokuno T, Nogi M, Jiu J, Suganuma K (2012) Hybrid transparent electrodes of silver nanowires and carbon nanotubes: a low-temperature solution process. Nanoscale Res Lett 7:281

Woo JS, Han JT, Jung S, Jang JI, Kim HY, Jeong HJ, Jeong SY, Baeg KJ, Lee GW (2014) Electrically robust metal nanowire network formation by in situ interconnection with single-walled carbon nanotubes. Sci Rep 4:4804

Krumbein SJ (1988) Metallic electromigration phenomena. IEEE Trans Compon Hybrids Manuf Technol 11:5–15

Javey A, Kong J (2009) Carbon nanotube electronics. Springer, New York

Amjadi M, Pichitpajongkit A, Lee S, Ryu S, Park I (2014) Highly stretchable and sensitive strain sensor based on silver nanowire elastomer nanocomposite. ACS Nano 8:5154–5163

Kim BS, Pyo JB, Son JG, Zi G, Lee S, Park JH, Lee J (2017) Biaxial stretchability and transparency of Ag nanowire 2D mass-spring networks prepared by floating compression. ACS Appl Mater Interfaces 9:10865–10873

Zhu Y, Qin Q, Xu F, Fan F, Ding Y, Zhang T, Wiley BJ, Wang ZL (2012) Size effects on elasticity, yielding, and fracture of silver nanowires: in situ experiments. Phys Rev B 85:45443

Xu F, Wang X, Zhu Y (2012) Wavy ribbons of carbon nanotubes for stretchable conductors. Adv Funct Mater 22:1279–1283

Lee MS, Kim J, Park J, Park JU (2015) Studies on the mechanical stretchability of transparent conductive film based on graphene-metal nanowire structures. Nanoscale Res Lett 10:27

Liang J, Li L, Tong K, Ren Z, Hu W, Niu X, Chen Y, Pei Q (2014) Silver nanowire percolation network soldered with graphene oxide at room temperature and its application for fully stretchable polymer light-emitting diodes. ACS Nano 8:1590–1600

Hong S, Lee H, Lee J, Kwon J, Han S, Suh YD, Cho H, Shin J, Yeo J, Ko SH (2015) Highly stretchable and transparent metal nanowire heater for wearable electronics applications. Adv Mater 27:4744–4751

Acknowledgements

This work was supported by LG Display academic industrial cooperation program (Grant No. 2016-11-1155).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The author declares that he has no competing financial interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Lee, S.J., Kim, JW., Park, J.H. et al. SWCNT–Ag nanowire composite for transparent stretchable film heater with enhanced electrical stability. J Mater Sci 53, 12284–12294 (2018). https://doi.org/10.1007/s10853-018-2526-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2526-7