Abstract

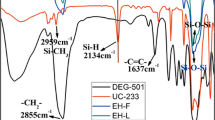

Phenolic resin/silicone hybrid composites (MPR) were prepared by a facile and low-cost method. FTIR results show that polycondensation of siloxane occurs in the presence of catalyst and water in the system, and siloxane oligomer was formed. During the curing process, the transesterification reaction between siloxane oligomer and phenolic resin (PR) makes silicon incorporated into PR. The TGA results indicate that introducing Si–O structure into PR can effectively improve the thermal stability of the resin. Compared with cured neat PR, temperatures at 5 and 10% mass loss of cured MPR can be improved by 43 and 36 °C. Its char yield at 800 °C was increased by about 9.1%. Cured MPR has been characterized by FTIR, XPS, XRD and Raman spectra to discuss the chemical state changes of silicon during pyrolysis process, as well as the effect of silicon on the char yield. On the one hand, the formation of Si–O–C structure can reduce the number of phenyl hydroxyl groups, which contributes to the reduced weight loss. On the other hand, the results indicate that Si–Ox structure was formed from the oxidation of Si–CH3 and hydrolysis of Si–O–C structures. According to Raman analyses, introducing silicone into the system cannot help to promote the formation of a more ordered structure. Additionally, the mechanical properties of cured MPR have also been improved.

Similar content being viewed by others

References

Pilato L (2013) Phenolic resins: 100 years and still going strong. React Funct Polym 73:270–277

Hirano K, Asami M (2013) Phenolic resins-100 years of progress and their future. React Funct Polym 73:256–269

Lei X, Chen Y, Zhang H, Zhang X, Yao P, Zhang Q (2013) Space survivable polyimides with excellent optical transparency and self-healing properties derived from hyperbranched polysiloxane. Appl Mater Interfaces 5:10207–10220

Pilato LA, Koo JH, Wissler GA, Lao S (2008) A review-phenolic and related resins and their nanomodification into phenolic resin FRP systems. J Adv Mater 40:5–16

Gu J, Dong W, Tang Y, Guo Y, Tang L, Kong J, Tadakamalla S, Wang B, Guo Z (2017) Ultralow dielectric fluoride-containing cyanate ester resins with improved mechanical properties and high thermal and dimensional stabilities. J Mater Chem C 5:6929–6936

Natali M, Kenny J, Torre L (2016) Science and technology of polymeric ablative materials for thermal protection systems and propulsion devices: a review. Prog Mater Sci 84:192–275

Deng P, Shi Y, Liu Y, Liu Y, Wang Q (2018) Solidifying process and flame retardancy of epoxy resin cured with boron-containing phenolic resin. Appl Surf Sci 427:894–904

Vanaja A, Rao R (2002) Synthesis and characterisation of epoxy-novolac/bismaleimide networks. Eur Polym J 38:187–193

Wang C, Zhao M, Li J, Yu J, Sun S, Ge S, Guo X, Xie F, Jiang B, Wujcik E, Huang Y, Wang N, Guo Z (2017) Silver nanoparticles/graphene oxide decorated carbon fiber synergistic reinforcement in epoxy-based composites. Polymer 131:263–272

Wu Z, Gao S, Chen L, Jiang D, Shao Q, Zhang B, Zhai Z, Wang C, Zhao M, Ma Y, Zhang X, Weng L, Zhang M, Guo Z (2017) Electrically insulated epoxy nanocomposites reinforced with synergistic core-shell SiO2@MWCNTs and montmorillonite bifillers. Macromol Chem Phys 218:1700357

Wang C, Wu Y, Li Y, Shao Q, Yan X, Han C, Wang Z, Liu Z, Guo Z (2018) Flame retardant rigid polyurethane foam with a phosphorus-nitrogen single intumescent flame retardant. Polym Adv Technol 29:668–676

Zhou P, Wang S, Tao C, Guo X, Hao L, Shao Q, Liu L, Wang Y, Chu W, Wang B, Luo S, Guo Z (2017) PAA/alumina composites prepared with different molecular weight polymers and utilized as support for nickel-based catalyst. Adv Polym Technol. https://doi.org/10.1002/adv.21908

Yang W, Wang X, Li J, Yan X, Ge S, Tadakamalla S, Guo Z (2017) Polyoxymethylene/ethylene butylacrylate copolymer/ethylene-methyl acrylate- glycidyl methacrylate ternary blends. Polym Eng Sci. https://doi.org/10.1002/pen.24675

He Y, Yang S, Liu H, Shao Q, Chen Q, Lu C, Jiang Y, Liu C, Guo Z (2018) Reinforced carbon fiber laminates with oriented carbon nanotube epoxy nanocomposites: magnetic field assisted alignment and cryogenic temperature mechanical properties. J Colloid Interface Sci 517:40–51

Gu A, Liang G, Lan L (1996) Modification of polyaralkyl-phenolic resin and its copolymer with bismalaimide. J Appl Polym Sci 59:975–979

Gao J, Liu Y, Yang L (1999) Thermal stability of boron-phenol formaldehyde resin. Polym Degrad Stab 63:19–22

Liu Y, Gao J, Zhang R (2002) Thermal properties and stability of boron-containing phenol-formaldehyde resin formed from paraformaldehyde. Polym Degrad Stab 77:495–501

Martín C, Ronda JC, Cádiz V (2006) Boron-containing novolac resins as flame retardant materials. Polym Degrad Stab 91:747–754

Wang J, Jiang N, Jiang H (2010) Micro-structural evolution of phenol-formaldehyde resin modified by boron carbide at elevated temperatures. Mater Chem Phys 120:187–192

Wang S, Jing X, Wang Y, Si J (2014) Synthesis and characterization of novel phenolic resins containing aryl-boron backbone and their utilization in polymeric composites with improved thermal and mechanical properties. Polym Adv Technol 25:152–159

Noparvar-Qarebagh A, Roghani-Mamaqani H, Salami-Kalajahi M (2016) Novolac phenolic resin and graphene aerogel organic-inorganic nanohybrids: high carbon yields by resin modification and its incorporation into aerogel network. Polym Degrad Stab 124:1–14

Lin C, Lee H, Chen J (2013) Synthesis and characterization of molybdenum/phenolic resin composites binding with aluminum nitride particles for diamond cutters. Appl Surf Sci 284:297–307

Yuan F, Zhang H, Li X, Ma H, Li X, Yu Z (2014) In situ chemical reduction and functionalization of graphene oxide for electrically conductive phenol formaldehyde composites. Carbon 68:653–661

Wang X, Liua X, Yuan H, Liu H, Liua C, Li T, Yan C, Yan X, Shen C, Guo Z (2018) Non-covalently functionalized graphene strengthened poly(vinyl alcohol). Mater Des 139:372–379

Zhang H, Liang G, Gu A, Yuan L (2014) Facile preparation of hyperbranched polysiloxane-grafted aramid fibers with simultaneously improved UV resistance, surface activity, and thermal and mechanical properties. Ind Eng Chem Res 53:2684–2696

Haraguchi K, Usami Y, Yamamura K, Matsumoto S (1998) Morphological investigation of hybrid materials composed of phenolic resin and silica prepared by in situ polymerization. Polymer 39:6243–6250

Haraguchi K, Usami Y, Ono Y (1998) The preparation and characterization of hybrid materials composed of phenolic resin and silica. J Mater Sci 33:3337–3344. https://doi.org/10.1023/A:1013237430504

Hernández-Padrón G, Rojas F, García-Garduňo M, Canseco M, Castaňo VM (2003) Development of hybrid materials consisting of SiO2 microparticles embedded in phenolic-formaldehydic resin polymer matrices. Mater Sci Eng 355:338–347

Chiang C, Ma C (2004) Synthesis, characterization, thermal properties and flame retardance of novel phenolic resin/silica nanocomposites. Polym Degrad Stab 83:207–214

Tuinstra F, Koening JL (1970) Raman spectrum of graphite. J Chem Phys 53:1126–1130

Kobera L, Czernek J, Strečková M, Urbanova M, Abbrent S, Brus J (2015) Structure and distribution of cross-links in boron-modified phenol-formaldehyde resins designed for soft magnetic composites: a multiple-quantum 11B–11B MAS NMR correlation spectroscopy study. Macromolecules 48:4874–4881

Niu S, Yan H, Chen Z, Li S, Xu P, Zhi X (2016) Unanticipated bright blue fluorescence produced from novel hyperbranched polysiloxanes carrying unconjugated carbon-carbon double bonds and hydroxyl groups. Polym Chem 7:3747–3755

Liu C, Li K, Li H, Zhang S, Zhang Y (2014) The effect of zirconium incorporation on the thermal stability and carbonized products of phenol-formaldehyde resin. Polym Degrad Stab 102:180–185

Satheesh Chandran M, Sunitha K, Gayathri DS, Soumyamol PB, Mathew Dona (2018) Boron-containing phenolic-siloxane hybrid polymers through facile click chemistry route. J Mater Sci 53:2497–2510. https://doi.org/10.1007/s10853-017-1737-7

Siqueira RL, Yoshida IVP, Pardini LC, Schiavon MA (2007) Poly(borosiloxanes) as precursors for carbon fiber ceramic matrix composites. Mater Res 10:147–151

Nguyen VL, Proust V, Quievryn C, Bernard S, Miele P, Soraru GD (2014) Processing, mechanical characterization, and alkali resistance of silicon boron oxycarbide (SiBOC) glass fibers. J Am Ceram Soc 97:3143–3149

Chen X, Ye J, Yuan L, Liang G, Gu A (2014) Multi-functional ladder-like polysiloxane: synthesis, characterization and its high performance flame retarding bismaleimide resins with simultaneously improved thermal resistance, dimensional stability and dielectric properties. J Mater Chem A 2:7491–7501

Wu T, Chen B (2016) Synthesis of multiwalled carbon nanotube-reinforced polyborosiloxane nanocomposites with mechanically adaptive and self-healing capabilities for flexible conductors. Appl Mater Interfaces 8:24071–24078

Lopez M, Blanco M, Vazquez A, Gabilondo N, Arbelaiz A, Echeverria JM, Mondragon I (2008) Curing characteristics of resol-layered silicate nanocomposites. Thermochim Acta 467:73–79

Kristkova M, Filip P, Weiss Z, Peter R (2004) Influence of metals on the phenol-formaldehyde resin degradation in friction composites. Polym Degrad Stab 84:49–60

Li S, Chen F, Han Y, Zhou H, Li H, Zhao T (2015) Enhanced compatibility and morphology evolution of hybrids involving phenolic resin and silicone intermediate. Mater Chem Phys 165:25–33

Li S, Han Y, Chen F, Luo Z, Li H, Zhao T (2016) The effect of structure on thermal stability and anti-oxidation mechanism of silicone modified phenolic resin. Polym Degrad Stab 124:68–76

Niu S, Yan H (2015) Novel hyperbranched polysiloxanes containing acetoacetyl groups synthesized through transesterification reaction. Macromol Rapid Commun 36:739–743

Duan Y, Jana SC, Lama B, Espe MP (2015) Self-crosslinkable poly (urethane urea)-reinforced silica aerogels. RSC Adv 5:71551–71558

Yin R, Cheng H, Hong C, Zhang X (2017) Synthesis and characterization of novel phenolic resin/silicone hybrid aerogel composites with enhanced thermal, mechanical and ablative properties. Compos Part A 101:500–510

Yan H, Li S, Jia Y, Ma X (2015) Hyperbranched polysiloxane grafted graphene for improved tribological performance of bismaleimide composites. RSC Adv 5:12578–12582

Niu S, Yan H, Li S, Tang C, Chen Z, Zhi X, Xu P (2016) A multifunctional silicon-containing hyperbranched epoxy: controlled synthesis, toughening bismaleimide and fluorescent properties. J Mater Chem C 4:6881–6893

Jiang H, Wang J, Wu S, Yuan Z, Hu Z, Wu R, Liu Q (2012) The pyrolysis mechanism of phenol formaldehyde resin. Polym Degrad Stab 97:1527–1533

Parker JA, Winkler EL (1967) The effects of molecular structure on the thermochemical properties of phenolics and related polymers, NASA TR R-276. Washington, DC

Klausmann K, Morita KE, Johanns C, Fasel K, Durst G, Mera R, Riedel E, Ionescu E (2015) Synthesis and high-temperature evolution of polysilylcarbodiimide-derived SiCN ceramic coatings. J Eur Ceram Soc 35:3771–3780

Kong J, Wang M, Zou J, An L (2015) Soluble and meltable hyperbranched polyborosilazanes toward high-temperature stable SiBCN ceramic. Appl Mater Interfaces 7:6733–6744

Ouchi K, Honda H (1959) Pyrolysis of coal 1. Thermal cracking of phenol-formaldehyde resins taken as coal models. Fuel 38:429–443

Jackson WM, Conley RT (1964) High temperature oxidative degradation of phenol-formaldehyde polycondensates. J Appl Polym Sci 8:2163–2193

Zhao Z, Ye G, Toghiani H, Pittman CU Jr (2010) Morphology and thermal stability of novolac phenolic resin/clay nanocomposites prepared via solution high-shear mixing. Macromol Mater Eng 295:923–933

Yun J, Chen L, Zhang X, Feng J, Liu L (2016) The effect of introducing B and N on pyrolysis process of high ortho novolac resin. Polymers 8:1–17

Wang S, Xing X, Wang Y, Wang W, Jing X (2017) Influence of poly (dihydroxybiphenyl borate) on the curing behaviour and thermal pyrolysis mechanism of phenolic resin. Polym Degrad Stab 144:378–391

Li S, Chen F, Zhang B, Luo Z, Li H, Zhao T (2016) Structure and improved thermal stability of phenolic resin containing silicon and boron elements. Polym Degrad Stab 133:321–329

Liotta LF, Gruttadauria M, Di Carlo G, Perrini G, Librando V (2009) Heterogeneous catalytic degradation of phenolic substrates: catalysts activity. J Hazard Mater 162:588–606

Wang Y, Chen L, Xu T, Yan Y, Gu J, Yun J, Feng J (2017) High char yield novolac modified by Si–B–N–C precursor: thermal stability and structural evolution. Polym Degrad Stab 137:184–196

Li C, Ma Z, Zhang X, Fan H, Wan J (2016) Silicone-modified phenolic resin: relationships between molecular structure and curing behavior. Thermochim Acta 639:53–65

Kumar BVM, Kim YW (2010) Processing of polysiloxane-derived porous ceramics: a review. Sci Technol Adv Mater 11:1–16

Wang S, Wang Y, Bian C, Zhong Y, Jing X (2015) The thermal stability and pyrolysis mechanism of boron-containing phenolic resins: the effect of phenyl borates on the char formation. Appl Polym Sci 331:519–529

Wang J, Jiang H, Jiang N (2009) Study on the pyrolysis of phenol-formaldehyde (PF) resin and modified PF resin. Thermochim Acta 496:136–142

Lei X, Qiao M, Tian L, Chen Y, Zhang Q (2015) Evolution of surface chemistry and morphology of hyperbranched polysiloxane polyimides in simulated atomic oxygen environment. Corros Sci 98:560–572

Tzeng S, Chr Y (2002) Evolution of microstructure and properties of phenolic resin-based carbon/carbon composites during pyrolysis. Mater Chem Phys 73:162–169

Laušević Z, Marinković S (1986) Mechanical properties and chemistry of carbonization of phenol formaldehyde resin. Carbon 24:575–580

Chen Y, Chen P, Hong C, Zhang B, Hui D (2013) Improved ablation resistance of carbon–phenolic composites by introducing zirconium diboride particles. Compos B 47:320–325

Wang H, Guo Q, Yang J, Liu Z, Zhao Y, Li J, Feng Z, Liu L (2013) Microstructural evolution and oxidation resistance of polyacrylonitrile-based carbon fibers doped with boron by the decomposition of BC4. Carbon 56:296–308

Huang J, Gao Y, Shao Q, Peng X, Guo Z (2017) Magnetic nanocarbon adsorbents with enhanced hexavalent chromium removal: morphology dependence of fibrillar vs particulate structures. Ind Eng Chem Res 56:10689–10701

Nikiel L, Jagodzinski PW (1999) Raman spectroscopic characterization of graphite: a re-evaluation of spectra/structure correlation. Carbon 31:1313–1317

Zhao X, Li Y, Wang J, Ouyang Z, Li J, Wei G, Su Z (2014) Interactive oxidation–reduction reaction for the in situ synthesis of graphene–phenol formaldehyde composites with enhanced properties. Appl Mater Interfaces 6:4254–4263

Chen Y, Zhou C, Chang J, Zou H, Liang M (2014) The effect of epoxy-silicone copolymer content on the thermal and mechanical properties of cured epoxy resin modified with siloxane. RSC Adv 4:60685–60693

Acknowledgements

This research is supported by Science and Technology Fund and Sponsored by the Seed Foundation of Innovation and Creation for Graduate Students in Northwestern Polytechnical University (No. Z2017046) and Shanghai Aerospace Science and Technology Innovation Fund (No. SAST2017-121).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest for this manuscript preparation and publishing.

Rights and permissions

About this article

Cite this article

Yun, J., Chen, L., Zhang, X. et al. Synthesis and structure evolution of phenolic resin/silicone hybrid composites with improved thermal stability. J Mater Sci 53, 14185–14203 (2018). https://doi.org/10.1007/s10853-018-2384-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2384-3