Abstract

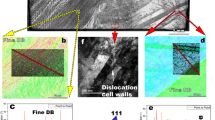

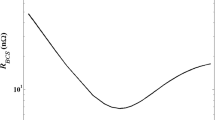

(100) Oriented niobium (Nb) crystals annealed in the vacuum conditions close to that used in mass production of 1.3 GHz superconducting radio frequency cavities for linear accelerators and treated in nitrogen at a partial pressure of 0.04 mbar at temperatures of 800 and 900 °C have been studied. The surfaces of the nitrogen-treated samples were investigated by means of various surface-sensitive techniques, including grazing-incidence X-ray diffraction, X-ray photoemission spectroscopy, and scanning electron microscopy with energy-dispersive X-ray spectroscopy in planar view and on cross-sections prepared by a focused ion beam. The appearance of a dense layer of epitaxial rectangular precipitates has been observed for the Niobium nitrided at 900 °C. Increased nitrogen concentration in the near-surface region was detected by glow-discharge optical-emission spectroscopy, focused ion-beam cross-sectional images and X-ray photoelectron spectroscopy. Crystalline phases of NbO and β-Nb2N were identified by X-ray diffraction. This information was confirmed by X-ray photoelectron measurements, which in addition revealed the presence of Nb2O5, NbON, NbN, and NbN x O y components on the surface. These results establish the near-surface Nb phase composition after high-temperature nitrogen treatment, which is important for obtaining a better understanding of the improved RF cavity performance.

Similar content being viewed by others

References

Ciovati G, Kneisel P, Gurevich A (2007) A Measurement of the high-field Q drop in a high-purity large-grain niobium cavity for different oxidation processes. Phys Rev Spec Top Accel Beams 10:062002

Ma Q, Rosenberg RA (2003) Angle-resolved X-ray photoelectron spectroscopy study of the oxides on Nb surfaces for superconducting rf cavity applications. Appl Sur Sci 206:209–217

Ciovati G, Myneni G, Stevie F, Maheshwari P, Griffis D (2010) High field Q slope and the baking effect: review of recent experimental results and new data on Nb heat treatments. Phys Rev Accel Beams 13:02200

Grassellino A, Romanenko A, Trenikhina Y, Checchin M, Martinello M, Melnychuk OS, Chandrasekaran S, Sergatskov DA, Posen S, Crawford AC, Aderhold S, Bice D (2017) Unprecedented quality factors at accelerating gradients up to 45 MV/m in niobium superconducting resonators via low temperature nitrogen infusion. Supercond Sci Technol 30:094004

Grassellino A, Romanenko A, Sergatskov D, Melnychuk O, Trenikhina Y, Crawford A, Rowe A, Wong M, Khabiboulline T, Barkov F (2013) Nitrogen and argon doping of niobium for superconducting radio frequency cavities: a pathway to highly efficient accelerating structures. Supercond Sci Technol 26:102001

Grassellino A, Romanenko A, Posen S, Trenikhina Y, Melnychuk O, Sergatskov DA, Merio M, Checchin M, Martinello M (2015) N doping: progress in development and understanding. In: Proceedings SRF2015, Whistler, BC, Canada, MOBA06, pp 48–754

Trenikhina Y, Grassellino A, Barkov F and Romanenko (2013) A chemical structure of niobium samples vacuum treated in nitrogen in parallel with very high Q0 cavities. In: Proceedings SRF2013, Paris, France, TUP065, pp 583–585

Trenikhina Y, Grassellino A, Melnychuk O and Romanenko A (2015) Characterization of nitrogen doping recipes for the Nb SRF cavities. In: Proceedings SRF2015, Whistler, BC, Canada, MOPB055, pp 223–227

Pham Tu M, Mbaye K, Wartski L, Halbritter J (1988) RF characterization of thermally diffused superconducting niobium nitride. J Appl Phys 63:4586–4590

Fabbricatore P, Fernandes P, Gualco G, Merlo F, Musenich R, Parodi R (1989) Study of niobium nitrides for superconducting rf cavities. J Appl Phys 66:5944–5949

Benvenuti C, Chiggiato P, Parrini L, Russo R (1993) Reactive diffusion produced niobium nitride films for superconducting cavity applications. Nuc Instr Meth Phys Res A Accel Spectrom Detect Assoc Equip 336:16–22

Fabbricatore P, Gemme G, Musenich R, Parodi R, Viviani M, Zhang B, Buscaglia V (1993) Niobium and niobium-titanium nitrides for RF applications. IEEE Trans Appl Supercond 3:1761–1764

Joguet M, Lengauer W, Bohn M, Bauer J (1998) High-temperature reactive phase formation in the Nb-N system. J Alloys Compound 269:233–237

Lengauer W, Bohn M, Wollein B, Lisak K (2000) Phase reactions in the Nb-N system below 1400 °C. Act Mat 48:2633–2638

Linde A, Marin-Ayral R-M, Granier D, Bosc-Rouessac F, Grachev V (2009) Synthesis of cubic niobium nitride by reactive diffusion under nitrogen pressure. Mater Res Bull 44:1025–1030

Ufuktepe Y, Farha AH, S-i Kimura et al (2013) Structural, electronic, and mechanical properties of niobium nitride prepared by thermal diffusion in nitrogen. Mater Chem Phys 141:393–400

Vonsovsky SV, Izyumov YA, Kurmaev EZ (1982) Superconductivity of transition metals. Springer, Berlin Heidelberg

Brauer G, Esselborn R (1961) Nitridphasen des Niobs. Zeits Anorg Allg Chem 309:151–170

Myneni GR (2007) Physical and mechanical properties of niobium for SRF science and technology. AIP Conference Proceedings 927:41

Series surface and acceptance test preparation of superconducting cavities for the European XFEL, Revision B/June 30, 2009, p 22

Deutsches Elektronen Synchrotron (DESY) (2016) DESY NanoLab. J Large Scale Res Facil 2:A76. https://doi.org/10.17815/jlsrf-2-140

Lohmeier M, Vlieg E (1993) Angle calculations for a six-circle surface X-ray diffractometer. J Appl Cryst 26:706–716

Vlieg E (1997) Integrated intensities using a six-circle surface X-ray diffractometer. J Appl Cryst 30:532–543

Dosch H (1992) Critical phenomena at surfaces and interfaces—evanescent X-ray and neutron-scattering. Springer Tracts Mod Phys 126:1

Albrecht WM and Goode Jr WD (1959) Reaction of nitrogen with niobium. Techn Rep BMI-1360, W-7405-ENG-92, Battelle Memorial Inst., Columbus, Ohio

Batchelor A, Leonard D, Russell P, Stevie F, Griffis D and Myneni G (2007) TEM and SIMS Analysis of (100),(110), and (111) Single Crystal Niobium. In: AIP Conference Proceedings, pp 72–83

Huang W (1996) Thermodynamic assessment of the Nb-N system. Metall Mater Trans A 27:3591–3600

Matylitskaya V, Bock W, Kolbesen B (2008) Nitridation of niobium oxide films by rapid thermal processing. Anal Bioanal Chem 390:1507–1515

Arfaoui I, Cousty J, Safa H (2002) Tiling of a Nb (110) surface with NbO crystals nanosized by the NbO/Nb misfit. Phys Rev B 65:115413

Delheusy M, Stierle A, Kasper N et al (2008) X-ray investigation of subsurface interstitial oxygen at Nb/oxide interfaces. Appl Phys Lett 92:101911

Darlinski A, Halbritter J (1987) Angle-resolved XPS studies of oxides at NbN, NbC, and Nb surfaces. Surf Interface Anal 10:223–237

Ramqvist L, Hamrin K, Johansson G, Gelius U, Nordling C (1970) VC, NbC and TaC with varying carbon content studied by ESCA. J Phys Chem Sol 31:2669–2672

Nedfors N, Tengstrand O, Lewin E, Furlan A, Eklund P, Hultman L, Jansson U (2011) Structural, mechanical and electrical-contact properties of nanocrystalline-NbC/amorphous-C coatings deposited by magnetron sputtering. Surf Coat Technol 206:354–359

Havey KS, Jabinski JS, Walck SD (1997) The chemistry, structure, and resulting wear properties of magnetron-sputtered NbN thin films. Thin Solid Films 303:238

Jouvey G, Severac C, Cantacuzene S (1996) XPS study of NbN and (NbTi)N superconducting coatings. Thin Solid Films 287:146

Sanjinés R, Benkahoul M, Sandu C, Schmid P, Lévy F (2006) Electronic states and physical properties of hexagonal β-Nb2 N and δ′-NbN nitrides. Thin Solid Films 494:190–195

Richter D, Töpler J, Springer T (1976) The influence of dissolved nitrogen and hydrogen in niobium studied by neutron spectroscopy. J. Phys. F Metal Phys 6:4

Metzger TH, Schubert U, Peisel J (1985) The trapping of hydrogen at nitrogen in niobium investigated by diffuse X-ray scattering. J Phys F Metal Phys 15:779

Gurevich A (2012) Superconducting radio-frequency fundamentals for particle accelerators. Rev Accel Sci Technol 5:119–146

Ciovati G (2004) Effect of low-temperature baking on the radio-frequency properties of niobium superconducting cavities for particle accelerators. J App Phys 96:1591

Dhakal P, Ciovati G, Myneni GR, Gray KE, Groll N, Maheshwari P, McRae DM, Pike R, Proslier T, Stevie F, Walsh RP, Yang Q, Zasadzinzki J (2013) Effect of high temperature heat treatments on the quality factor of a large-grain superconducting radio-frequency niobium cavity. Phys. Rev Spec Top Accel. Beams 16:042001

Acknowledgements

Authors declare that no conflict of interests exist. Support on the material from Xenia Singer, and for the FIB preparation and the SEM analysis by S. Kulkarni at the DESY NanoLab, is acknowledged. We acknowledge the use of the focused ion-beam instrument at the DESY NanoLab funded by the BMBF Grant No. 5K13WC3 (PT-DESY). Authors GSD, AP, and BF acknowledge funding from the BMBF grant no. 05H15GURBB.

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Dangwal Pandey, A., Dalla Lana Semione, G., Prudnikava, A. et al. Surface characterization of nitrogen-doped Nb (100) large-grain superconducting RF cavity material. J Mater Sci 53, 10411–10422 (2018). https://doi.org/10.1007/s10853-018-2310-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2310-8