Abstract

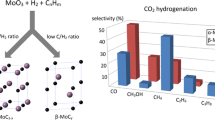

We have examined the catalytic action of β- and γ-Mo2N in the partial hydrogenation of acetylene. The influence of variations in GHSV (230–1600 min−1), feed composition (5–30% v/v N2/H2), heating rate (0.1–5 K min−1) and isothermal hold (1–7 h at 933 K) on nitride structural properties has been assessed. At ≥ 2 K min−1, β-Mo2N (≤ 15 m2 g−1) consisting of small crystallites (< 5 μm) was generated. At ≤ 0.5 K min−1, γ-Mo2N with a platelet morphology and surface area ≥ 45 m2 g−1 was formed. High GHSV, low N2 feed content and a prolonged isothermal hold served to increase γ-Mo2N area (to 135 m2 g−1). Lower alkene selectivity and a twofold higher specific (per m2) acetylene hydrogenation rate were recorded for β-Mo2N and linked to higher surface Mo/N ratio (from XPS). Olefin selectivity for both nitrides was greater than that reported for Pd catalysts. Moreover, we recorded negligible green oil formation in reactions over γ-Mo2N.

Similar content being viewed by others

References

Furimsky E (2003) Metal carbides and nitrides as potential catalysts for hydroprocessing. Appl Catal A Gen 240:1–28

Guerrero-Ruiz A, Zhang Y, Bachiller-Baeza B, Rodríguez-Ramos I (1998) Hydrogenation of crotonaldehyde over carbon-supported molybdenum nitrides. Catal Lett 55:165–168

Cárdenas-Lizana F, Lamey D, Perret N, Gómez-Quero S, Kiwi-Minsker L, Keane MA (2012) Au/Mo2N as a new catalyst formulation for the hydrogenation of p-chloronitrobenzene in both liquid and gas phases. Catal Commun 21:46–51

Hargreaves JSJ (2013) Heterogeneous catalysis with metal nitrides. Coord Chem Rev 257:2015–2031

Mckay D, Hargreaves JSJ, Rico JL, Rivera JL, Sun X-L (2008) The influence of phase and morphology of molybdenum nitrides on ammonia synthesis activity and reduction characteristics. J Solid State Chem 181:325–333

Nagai M, Goto Y, Miyata A, Kiyoshi M, Hada K, Oshikawa K, Omi S (1999) Temperature-programmed reduction and XRD studies of ammonia-treated molybdenum oxide and its activity for carbazole hydrodenitrogenation. J Catal 182:292–301

Perret N, Cárdenas-Lizana F, Lamey D, Laporte V, Kiwi-Minsker L, Keane MA (2012) Effect of crystallographic phase (β vs. γ) and surface area on gas phase nitroarene hydrogenation over Mo2N and Au/Mo2N. Top Catal 55:955–968

Cárdenas-Lizana F, Gómez-Quero S, Perret N, Kiwi-Minsker L, Keane MA (2011) β-Molybdenum nitride: synthesis mechanism and catalytic response in the gas phase hydrogenation of p-chloronitrobenzene. Catal Sci Technol 1:794–801

Cairns AG, Gallagher JG, Hargreaves JSJ, McKay D, Rico JL, Wilson K (2010) The effect of low levels of dopants upon the formation and properties of beta-phase molybdenum nitride. J Solid State Chem 183:613–619

Jujjuri S, Cárdenas-Lizana F, Keane MA (2014) Synthesis of group VI carbides and nitrides: application in catalytic hydrodechlorination. J Mater Sci 49:5406–5417. https://doi.org/10.1007/s10853-014-8252-x

Cairns AG, Gallagher JG, Hargreaves JSJ, Mckay D, Morrison E, Rico JL, Wilson K (2009) The influence of precursor source and thermal parameters upon the formation of beta-phase molybdenum nitride. J Alloys Compd 479:851–854

Choi J-G, Curl RL, Thompson LT (1994) Molybdenum nitride catalysts. I. Influence of the synthesis factors on structural properties. J Catal 146:218–227

Markel EJ, Burdick SE, Leaphart ME II, Roberts KL (1999) Synthesis, characterization, and thiophene desulfurization activity of unsupported γ-Mo2N macrocrystalline catalysts. J Catal 182:136–147

Zhivonitko VV, Skovpin IV, Crespo-Quesada M, Kiwi-Minsker L, Koptyug IV (2016) Acetylene oligomerization over Pd nanoparticles with controlled shape: a parahydrogen-induced polarization study. J Phys Chem C 120:4945–4953

Larsson M, Jansson J, Asplund S (1998) The role of coke in acetylene hydrogenation on Pd/α-Al2O3. J Catal 178:49–57

Ahn IY, Lee JH, Kum SS, Moon SH (2007) Formation of C4 species in the deactivation of a Pd/SiO2 catalyst during the selective hydrogenation of acetylene. Catal Today 123:151–157

Yang B, Burch R, Hardacre C, Hu P, Hughes P (2014) Mechanistic study of 1,3-butadiene formation in acetylene hydrogenation over the Pd-based catalysts using density functional calculations. J Phys Chem C 118:1560–1567

Larsson M, Jansson J, Asplund S (1996) Incorporation of deuterium in coke formed on an acetylene hydrogenation catalyst. J Catal 162:365–367

Hao ZX, Wei ZB, Wang LJ, Li XH, Li C, Min EZ, Xin Q (2000) Selective hydrogenation of ethyne on γ-Mo2N. Appl Catal A Gen 192:81–84

Cárdenas-Lizana F, Crespo-Quesada M, Kiwi-Minsker L (2012) Selective alkyne hydrogenation over nano-metal systems: closing the gap between model and real catalysts for industrial applications. Chimia 66:681–686

Pachulski A, Schödel R, Claus P (2011) Performance and regeneration studies of Pd-Ag/Al2O3 catalysts for the selective hydrogenation of acetylene. Appl Catal A Gen 400:14–24

Lamey D, Prokopyeva I, Cárdenas-Lizana F, Kiwi-Minsker L (2014) Impact of organic-ligand shell on catalytic performance of colloids for alkyne gas-phase hydrogenation. Catal Today 235:79–89

Bartholomew CH (2001) Mechanisms of catalyst deactivation. Appl Catal A Gen 212:17–60

Crespo-Quesada M, Cárdenas-Lizana F, Dessimoz A-L, Kiwi-Minsker L (2012) Modern trends in catalyst and process design for alkyne hydrogenations. ACS Catal 2:1773–1786

McCue AJ, Anderson JA (2015) Recent advances in selective acetylene hydrogenation using palladium containing catalysts. Front Chem Sci Eng 9:142–153

Fransen T, Berge PC, Mars P (1976) Reduced molybdenum oxide catalysts with high surface areas. Preparation and activities. React Kinet Catal Lett 5:445–452

Quincy RB, Houalla M, Proctor A, Hercules DM (1990) Distribution of molybdenum oxidation states in reduced Mo/TiO2 catalysts: correlation with benzene hydrogenation activity. J Phys Chem 94:1520–1526

Ruta M, Semagina N, Kiwi-Minsker L (2008) Monodispersed Pd nanoparticles for acetylene selective hydrogenation: particle size and support effects. J Phys Chem C 112:13635–13641

Jauberteau I, Mayet R, Cornette J, Bessaudou A, Carles P, Jauberteau J-L, Merle-Méjean T (2015) A reduction–nitridation process of molybdenum films in expanding microwave plasma: crystal structure of molybdenum nitrides. Surf Coat Technol 270:77–85

Pande P, Deb A, Sleightholme AES, Djire A, Rasmussen PG, Penner-Hahn J, Thompson LT (2015) Pseudocapacitive charge storage via hydrogen insertion for molybdenum nitrides. J Power Sources 289:154–159

Jaggers CH, Michaels JN, Stacy AM (1990) Preparation of high-surface-area transition-metal nitrides: Mo2N and MoN. Chem Mater 2:150–157

Dewangan K, Patil SS, Joag DS, More MA, Gajbhiye NS (2010) Topotactical nitridation of α-MoO3 fibers to γ-Mo2N fibers and its field emission properties. J Phys Chem C 114:14710–14715

Sha X, Chen L, Cooper AC, Pez GP, Cheng H (2009) Hydrogen absorption and diffusion in bulk α-MoO3. J Phys Chem C 113:11399–11407

Zeng HC, Ng WK, Cheong LH, Xie F, Xu R (2001) Insertion direction of hydrogen in protonation of α-MoO3. J Phys Chem B 105:7178–7181

Birtill JJ, Dickens PG (1979) Thermochemistry of hydrogen molybdenum bronze phases HXMoO3. J Solid State Chem 29:367–372

Volpe L, Boudart M (1985) Compounds of molybdenum and tungsten with high specific surface area: I. nitrides. J Solid State Chem 59:332–347

Ji W, Shen R, Yang R, Yu G, Guo X, Peng L, Ding W (2014) Partially nitrided molybdenum trioxide with promoted performance as an anode material for lithium-ion batteries. J Mater Chem A 2:699–704

Jauberteau I, Bessaudou A, Mayet R, Cornette J, Jauberteau J, Carles P, Merle-Méjean T (2015) Molybdenum nitride films: crystal structures, synthesis, mechanical, electrical and some other properties. Coatings 5:656–687

Roberts KL, Markel EJ (1994) Generation of Mo2N nanoparticles from topotactic Mo2N crystallites. J Phys Chem 98:4083–4086

Ikhlaq U, Ahmad R, Shafiq M, Saleem S, Shah MS, Hussain T, Khan IA, Abbas K, Abbas MS (2014) Nitriding molybdenum: effects of duration and fill gas pressure when using 100-Hz pulse DC discharge technique. Chin Phys B 23:1052031–1052038

Schulmeyer WV, Ortner HM (2002) Mechanisms of the hydrogen reduction of molybdenum oxides. Int J Refract Hard Mater 20:261–269

Oyama ST (1996) The chemistry of transition metal carbides and nitrides, vol 1, 1st edn. Blackie Academic, Glasgow

Ogi T, Kaihatsu Y, Iskandar F, Tanabe E, Okuyama K (2009) Synthesis of nanocrystalline GaN from Ga2O3 nanoparticles derived from salt-assisted spray pyrolysis. Adv Powder Technol 20:29–34

Wise RS, Markel EJ (1994) Synthesis of high surface area molybdenum nitride in mixtures of nitrogen and hydrogen. J Catal 145:344–355

Fuertes A (2015) Metal oxynitrides as emerging materials with photocatalytic and electronic properties. Mater Horiz 2:453–461

Sakagami H, Asano Y, Takahashi N, Matsuda T (2005) H2 reduction of hydrogen molybdenum bronze to porous molybdenum oxide and its catalytic properties for the conversions of pentane and propan-2-ol. Appl Catal A Gen 284:123–130

Büchele W, Roos H, Wanjek H, Müller HJ (1996) Catalyst research—one of the cornerstones of modern chemical production. Catal Today 30:33–39

Jaf ZN, Altarawneh M, Miran HA, Jiang Z-T, Dlugogorski BZ (2017) Mechanisms governing selective hydrogenation of acetylene over γ-Mo2N surfaces. Catal Sci Technol 7:943–960

Bridier B, Pérez-Ramírez J (2010) Cooperative effects in ternary Cu–Ni–Fe catalysts lead to enhanced alkene selectivity in alkyne hydrogenation. J Am Chem Soc 132:4321–4327

Lee DK (1990) Green-oil formation and selectivity change in selective hydrogenation on titania-supported and unsupported palladium catalyst for acetylene removal from ethylene-rich stream. Korean J Chem Eng 7:233–235

Hartog AJD, Deng M, Jongerius F, Ponec V (1990) Hydrogenation of acetylene over various group VIII metals: effect of particle size and carbonaceous deposits. J Mol Catal 60:99–108

Zhang J, Sui Z, Zhu Y-A, Chen D, Zhou X, Yuan W (2016) Composition of the green oil in hydrogenation of acetylene over a commercial Pd-Ag/Al2O3 catalyst. Chem Eng Technol 39:865–873

Zhou G, Wang P, Jiang Z, Ying P, Li C (2011) Selective hydrogenation of acetylene over a MoP catalyst. Chin J Catal 32:27–30

Yajun L, Jing Z, Xueru M (1982) Formation of polymers during the hydrogenation of acetylene in ethylene–ethane fraction. In: AIChE (ed) Joint meeting of chemical engineering, Beijing, China. Chemical Industry Press, Beijing, p 926

Prins R (2012) Hydrogen spillover. Facts and fiction. Chem Rev 112:2714–2738

Zhang YJ, Li YX, Li C, Xin Q (1997) Adsorption and migration of Hydrogen on different surface sites of γ-Mo2N catalyst. Spillover and migration of surface species on catalysis, vol 112, 1st edn. Elsevier, Amsterdam

Nagai M, Goto Y, Uchino O, Omi S (1998) TPD study and carbozole hydrodenitrogenation activity of nitrided molybdena–alumina. Catal Today 45:335–340

Li XS, Chen YX, Zhang YJ, Ji CX, Xin Q (1996) Temperature-programmed desorption and adsorption of hydrogen on Mo2N. React Kinet Catal Lett 58:391–396

Li XS, Zhang YJ, Xin Q, Ji CX, Miao YF, Wang L (1996) Irreversible hydrogen uptake on Mo2N catalyst. React Kinet Catal Lett 57:177–182

Nagai M, Goto Y, Uchino O, Omi S (1998) TPD and XRD studies of molybdenum nitride and its activity for hydrodenitrogenation of carbazole. Catal Today 43:249–259

Vilé G, Albani D, Almora-Barrios N, López N, Pérez-Ramírez J (2016) Advances in the design of nanostructured catalysts for selective hydrogenation. ChemCatChem 8:21–33

Acknowledgements

Financial support from the Swiss National Science Foundation and the Russian Science Foundation (Project 15-19-20023) is acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Cárdenas-Lizana, F., Lamey, D., Kiwi-Minsker, L. et al. Molybdenum nitrides: a study of synthesis variables and catalytic performance in acetylene hydrogenation. J Mater Sci 53, 6707–6718 (2018). https://doi.org/10.1007/s10853-018-2009-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2009-x