Abstract

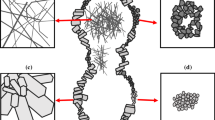

Cordierite-bonded porous SiC ceramics were prepared by air sintering of cordierite sol infiltrated porous powder compacts of SiC with graphite and polymer microbeads as pore-forming agents. The effect of sintering temperature, type of pore former and its morphology on microstructure, mechanical strength, phase composition, porosity and pore size distribution pattern of porous SiC ceramics were investigated. Depending on type and size of pore former, the average pore diameter, porosities and flexural strength of the final ceramics sintered at 1400 °C varied in the range of ~ 7.6 to 10.1 µm, 34–49 vol% and 34–15 MPa, respectively. The strength–porosity relationship was explained by the minimum solid area (MSA) model. After mechanical stress was applied to the porous SiC ceramics, microstructures of fracture surface appeared without affecting dense struts of thickness ~ 2 to 10 µm showing restriction in crack propagation through interfacial zone of SiC particles. The effect of corrosion on oxide bond phases was investigated in strong acid and basic salt medium at 90 °C. The residual mechanical strength, SEM micrographs and EDX analyses were conducted on the corroded samples and explained the corrosion mechanisms.

Similar content being viewed by others

References

Adler J (2005) Ceramic diesel particulate filters. Int J Appl Ceram Technol 2:429–439

Wilkes TE, Young ML, Sepulved RE, Dunand DC, Faber KT (2006) Composites by aluminum infiltration of porous silicon carbide derived from wood precursors. Scr Mater 55:1083–1086

Wach RA, Sugimoto M, Yoshikawa M (2007) Formation of silicone carbide membrane by radiation curing of polycarbosilane and polyvinylsilane and its gas separation up to 250°C. J Am Ceram Soc 90:275–278

Vogt UF, Györfy L, Herzog A, Graule T, Plesch G (2007) Macroporous silicon carbide foams for porous burner applications and catalyst supports. J Phys Chem Solids 68:1234–1238

Kumar BVM, Roh M-H, Kim Y-W, Kim W, Park S-W (2010) Mechanical properties of SiC ceramics sintered with RE2O3 (RE: Sc, Lu, Y) and AlN additives. Met Mater Int 16:229–233

Eom J-H, Kim Y-W (2010) Effect of additives on mechanical properties of macroporous silicon carbide ceramics. Met Mater Int 16:399–405

Kumar BVM, Kim Y-W (2010) Processing of polysiloxane-derived porous ceramics: a review. Sci Technol Adv Mater 11:044303-1–044303-16

Eom J-H, Ki Y-W, Raju S (2013) Processing and properties of macroporous silicon carbide ceramics: a review. J Asian Ceram Soc. 1:220–242

Sigl LS, Kleebe H-J (1993) Core/Rim structure of liquid-phase-sintered silicon carbide. J Am Ceram Soc 76:773–776

Pastila P, Helanti V, Nikkilä A-P, Mäntylä T (2001) Environmental effects on microstructure and strength of SiC-based hot gas filters. J Eur Ceram Soc 21:1261–1268

She JH, Deng ZY, Daniel-Doni J, Ohji T (2002) Oxidation bonding of porous silicon carbide ceramics. J Mater Sci 37:3615–3622. https://doi.org/10.1023/A:1016596805717

Ding S, Zhu S, Zeng Y-P, Jiang D (2007) Fabrication of mullite-bonded porous silicon carbide ceramics by in situ reaction bonding. J Eur Ceram Soc 27:2095–2102

Ebrahimpour O, Dubois C, Chaouki J (2014) Fabrication of mullite-bonded porous SiC ceramics via a sol–gel assisted in situ reaction bonding. J Eur Ceram Soc 34:237–247

She JH, Ohji T (2003) Fabrication and characterization of highly porous mullite ceramics. Mater Chem Phys 80:610–614

Ding S, Zeng Y-P, Jiang D (2008) In-situ reaction bonding of porous SiC ceramics. Mater Charact 59:140–143

Liu S, Zeng Y-P, Jiang D (2009) Fabrication and characterization of cordierite-bonded porous SiC ceramics. Ceram Int 35:597–602

Ding S, Zhu S, Zeng Y, Jiang D (2006) Effect of Y2O3 addition on the properties of reaction-bonded porous SiC ceramics. Ceram Int 32:461–466

Zhu S, Ding S, Xi H, Li Q, Wang R (2007) Preparation and characterization of SiC/cordierite composite porous ceramics. Ceram Int 33:115–118

Liu S, Zeng Y-P, Jiang D (2009) Effects of CeO2 addition on the properties of cordierite-bonded porous SiC ceramics. J Eur Ceram Soc 29:1795–1802

Bai C-Y, Deng X-Y, Li J-B, Jing Y-N, Jiang W-K, Liu Z-M, Li Y (2014) Fabrication and properties of cordierite–mullite bonded porous SiC ceramics. Ceram Int 40:6225–6231

Lee S-H, Kim Y-W (2006) Processing of cellular SiC ceramics using polymer microbeads. J Korean Ceram Soc 43:458–462

Li J, Lin H, Li J (2011) Factors that influence the flexural strength of SiC-based porous ceramics used for hot gas filter support. J Eur Ceram Soc 31:825–831

Shi W, Liu B, Deng X, Li J, Yang Y (2016) In-situ synthesis and properties of cordierite-bonded porous SiC membrane supports using diatomite as silicon source. J Eur Ceram Soc 36:3465–3472

Baitalik S, Kayal N (2017) Processing and properties of cordierite-silica bonded porous SiC ceramics. Ceram Int 43:14683–14692

Wang S, Kuang F (2010) Sol-gel preparation and infrared radiation property of boron-substituted cordierite glass-ceramics. J Mater Sci Technol 26:445–448

Kayal N, Dey A, Chakrabarti O (2012) Synthesis of mullite bonded porous SiC ceramics by a liquid precursor infiltration method: effect of sintering temperature on material and mechanical properties. J Mater Sci Eng A 556:789–795

Corbin SF, Lee J, Qiao X (2001) Influence of green formulation and pyrolyzable particulates on the porous microstructure and sintering characteristics of tape cast ceramics. J Am Ceram Soc 84:41–47

Eom J-H, Kim Y-W, Song I-H (2012) Effects of the initial α-SiC content on the microstructure, mechanical properties, and permeability of macroporous silicon carbide ceramics. J Eur Ceram Soc 32:1283–1290

Shi ZM, Liang KM, Gu SR (2001) Effects of CeO2 on phase transformation towards cordierite in MgO–Al2O3–SiO2 system. Mater Lett 51:68–72

El-Buaishi NM, Janković-Častvan I, Jokić B, Veljović D, Janaćković D, Petrović R (2012) Crystallization behavior and sintering of cordierite synthesized by an aqueous sol–gel route. Ceram Int 38:1835–1841

Dey A, Kayal N, Chakrabarti O (2011) Preparation of porous SiC ceramics by an infiltration technique. Ceram Int 37:223–230

Rice RW (1996) Evaluation and extension of physical property-porosity models based on minimum solid area. J Mater Sci 31:102–118. https://doi.org/10.1007/BF00355133

She J, Yang J-F, Kondo N, Ohji T, Kanzaki S, Deng Z-Y (2002) High-strength porous silicon carbide ceramics by an oxidation-bonding technique. J Am Ceram Soc 85:2852–2854

Chun Y-S, Kim Y-W (2005) Processing and mechanical properties of porous silica-bonded silicon carbide ceramics. Met Mater Int 11:351–355

Eom J-H, Kim Y-W (2008) Effect of template size on microstructure and strength of porous silicon carbide ceramics. J Ceram Soc Jpn 116:1159–1163

Eom J-H, Kim Y-W (2012) Effect of initial α-phase content on microstructure and flexural strength of macroporous silicon carbide ceramics. Met Mater Int 18:379–383

Schilm J, Herrmann M, Michael G (2004) Leaching behaviour of silicon nitride materials in sulphuric acid containing KF. J Eur Ceram Soc 24:2319–2327

Schilm J, Herrmann M, Michael G (2007) Corrosion of Si3N4-ceramics in aqueous solutions Part 2. Corrosion mechanisms in acids as a function of concentration, temperature and composition. J Eur Ceram Soc 27:3573–3588

Kenedy CR (1981) Alkali attack on a mullite refractory in the grand forks energy technology center slagging gasifier. J Mater Energy Syst 3:27–31

Acknowledgements

The authors would like to thank SERB, Department of Science and Technology, Government of India (GAP-0239), for financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Baitalik, S., Dalui, S.K. & Kayal, N. Mechanical and microstructural properties of cordierite-bonded porous SiC ceramics processed by infiltration technique using various pore formers. J Mater Sci 53, 6350–6365 (2018). https://doi.org/10.1007/s10853-018-2007-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-018-2007-z