Abstract

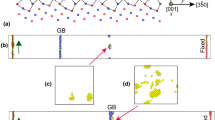

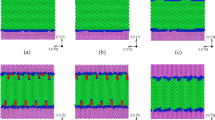

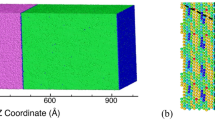

Molecular dynamics (MD) simulations are used to investigate the role of size and distribution of nanoscale Cu/Ta interfaces on the nucleation and evolution of defects during shock loading and spall failure of nanocrystalline (nc) Cu/Ta alloys. Cu/Ta interfaces are introduced through the embedding of Ta clusters in nc-Cu matrix. The phase stability of the embedded Ta clusters either as FCC or BCC clusters is first investigated and reveals that the FCC Ta clusters have a lower energy for diameters less than 4 nm, whereas the BCC Ta clusters have a lower energy for the larger diameters. The shock simulations are then carried out for Ta clusters with an average diameter of 1 and 3 nm and concentrations of 3.0, 6.3 and 10.0% to investigate the role of size and distribution of Cu/Ta interfaces (due to presence of clusters) on the nucleation and evolution of dislocations as well as the spall strength of the alloy. The MD simulations indicate that the Cu/Ta interfaces reduce the capability of nc-Cu to accommodate plasticity through nucleation of dislocations and create void nucleation sites during spallation. The MD simulations further reveal that the impact strengthening effects due to the presence of nanoscale Cu/Ta interfaces are strongly dependent upon the size and distribution of Ta clusters, as well as the grain size of Cu matrix. Smaller size of interfaces (cluster size), higher concentration of Ta (smaller spacing between interfaces) and larger matrix grain size render higher spall strengths of nc-Cu/Ta microstructures.

Similar content being viewed by others

References

Ma E (2005) Alloys created between immiscible elements. Prog Mater Sci 50:413–509

Zhu T, Li J (2010) Ultra-strength materials. Prog Mater Sci 55:710–775

Kumar KS, Swygenhoven HV, Suresh S (2003) Mechanical behavior of nanocrystalline metals and alloys. Acta Mater 51:5743–5574

Lei RS, Wang MP, Wang HP, Xu SQ (2016) New insights on the formation of supersaturated Cu-Nb solid solution prepared by mechanical alloying. Mater Charact 118:324–331

Kapoora M, Kaub T, Darling KA et al (2017) An atom probe study on Nb solute partitioning and nanocrystalline grain stabilization in mechanically alloyed Cu-Nb. Acta Mater 126:564–575

Wang M, Averback RS, Bellon P et al (2014) Chemical mixing and self-organization of Nb precipitates in Cu during severe plastic deformation. Acta Mater 62:276–285

He WX, Wang E, Hu LX et al (2008) Effect of extrusion on microstructure and properties of a submicron crystalline Cu–5 wt% Cr alloy. J Mater Process Technol 208:205–210

Chbihi A, Sauvage X, Blavette D (2012) Atomic scale investigation of Cr precipitation in copper. Acta Mater 60:4575–4585

Eckert J, Holzer JC, Johnson WL (1993) Thermal stability and grain growth behavior of mechanically alloyed nanocrystalline Fe–Cu alloys. J Appl Phys 73:131–141

Sauvage X, Wetscher F, Pareige P et al (2005) Mechanical alloying of Cu and Fe induced by severe plastic deformation of a Cu–Fe composite. Acta Mater 53:2127–2135

Bao GH, Chen CX, Huang LY et al (2016) Deformation of Fe and Ag precipitates in Cu matrix. Mater Sci Eng, A 655:86–91

Atwater MA, Roy D, Darling KA et al (2012) The thermal stability of nanocrystalline copper cryogenically milled with tungsten. Mater Sci Eng, A 558:226–233

Tai KP, Averback RS, Bellon P et al (2012) Temperature dependence of irradiation-induced creep in dilute nanostructured Cu–W alloys. J Nucl Mater 422:8–13

Shu SP, Zhang X, Beach JA et al (2016) Irradiation-induced formation of nanorod precipitates in a dilute Cu–W alloy. Scr Mater 115:155–158

Zhang X, Beach JA, Wang M et al (2016) Precipitation kinetics of dilute Cu–W alloys during low-temperature ion irradiation. Acta Mater 120:46–55

Minich RW, Cazamias JU, Kumar M et al (2004) Effect of microstructural length scales on spall behavior of copper. Metall Trans A 35A:2664–2673

Williams CL, Sano T, Walter TR et al (2016) The role of second phase intermetallic particles on the spall failure of 5083 aluminum. J Dyn Behav Mater 2:476–483

Hixson RS, Johnson JN, Gray GT III et al (1996) AIP Conf Proc 370:555–558

National Research Council (2011) Opportunities in protection materials science and technology for future army applications. The National Academies Press, Washington, DC

Meyers MA (1994) Dynamic behavior of materials. Wiley, New York

Remingtona TP, Remingtonb BA, Hahna EN et al (2017) Deformation and failure in extreme regimes by high-energy pulsed lasers: a review. Mater Sci Eng A 68:429–458

Kanel GI (2010) Spall fracture: methodological aspects, mechanisms and governing factors. Int J Fract 163:173–191

Escobedo JP, Dennis-Koller D, Cerreta EK et al (2011) Effects of grain size and boundary structure on the dynamic tensile response of copper. J Appl Phys 110:033513

Lin EQ, Shi HJ, Niu LS (2014) Effects of orientation and vacancy defects on the shock Hugoniot behavior and spallation of single-crystal copper. Modell Simul Mater Sci Eng 22:035012

Wayne L, Krishnan K, DiGiacomo S et al (2010) Statistics of weak grain boundaries for spall damage in polycrystalline copper. Scr Mater 63:1065–1068

Pedrazas NA, Worthingtonb DL, Dalton DA et al (2012) Effects of microstructure and composition on spall fracture in aluminum. Mater Sci Eng, A 536:117–123

Hazell PJ, Appleby-Thomas GJ, Wielewski E et al (2012) The influence of microstructure on the shock and spall behaviour of the magnesium alloy, Elektron 675. Acta Mater 60:6042–6050

Fensin SJ, Escobedo JP, Gray GT III et al (2014) Dynamic damage nucleation and evolution in multiphase materials. J Appl Phys 115:203516

Feng Q, Song LN, Zeng YW et al (2015) Evolution of FCC/BCC interface and its effect on the strengthening of severe drawn Cu–3 wt% Cr. J Alloys Compd 640:45–50

Han WZ, Cerreta EK, Mara NA et al (2014) Deformation and failure of shocked bulk Cu–Nb nanolaminates. Acta Mater 63:150–161

Anderson PM, Li C (1995) Hall-Petch relations for multilayered materials. Nanostruct Mater 5:349–362

Li N, Wang J, Misra A et al (2012) Direct observations of confined layer slip in Cu/Nb multilayers. Microsc Microanal 18:1155–1162

Shi J, Cao ZH, Wei MZ et al (2014) Anomalous softening behavior in Ti/Ni multilayers with ultra-high hardness. Mater Sci Eng, A 618:385–388

Lu YY, Kotoka R, Ligda JP et al (2014) The microstructure and mechanical behavior of Mg/Ti multilayers as a function of individual layer thickness. Acta Mater 63:216–231

Darling KA, Huskins EL, Schuster BE, Wei Q, Kecskes LJ (2015) Mechanical properties of a high strength Cu–Ta composite at elevated temperature. Mater Sci Eng A 638:322–328

Rojhirunsakoo T, Darling KA, Tschopp MA (2015) Structure and thermal decomposition of a nanocrystalline mechanically alloyed supersaturated Cu–Ta solid solution. MRS Commun 5:333–339

Rajagopalan M, Darling K, Turnage S et al (2017) Microstructural evolution in a nanocrystalline Cu–Ta alloy: a combined in situ TEM and atomistic study. Mater Des 113:178–185

Darling KA, Tschopp MA, Guduru RK et al (2014) Microstructure and mechanical properties of bulk nanostructured Cu–Ta alloys consolidated by equal channel angular extrusion. Acta Mater 76:168–185

Hornbuckle BC, Rojhirunsakool T, Rajagopalan M et al (2015) Effect of Ta solute concentration on the microstructural evolution in immiscible Cu–Ta Alloys. JOM 67(12): 2802–2809

Darling KA, Roberts AJ, Mishin Y et al (2013) Grain size stabilization of nanocrystalline copper at high temperatures by alloying with tantalum. J Alloys Compd 573:142–150

Darling KA, Rajagopalan M, Komarasamy M et al (2016) Extreme creep resistance in a microstructurally stable nanocrystalline alloy. Nature 537: 378–381

Han WZ, An Q, Luo SN et al (2012) Deformation and spallation of shocked Cu bicrystals with Sigma3 coherent and symmetric incoherent twin boundaries. Phys Rev B 85:024107

Fensin SJ, Escobedo-Diaz JP, Brandl C (2014) Effect of loading direction on grain boundary failure under shock loading. Acta Mater 64:113–122

An Q, Han WZ, Luo SN et al (2012) Left-right loading dependence of shock response of (111)//(112) Cu bicrystals: deformation and spallation bicrystals: deformation and spallation. J Appl Phys 111:053525

Dongare AM, Rajendran AM, LaMattina B, Zikry MA, Brenner DW (2009) Atomic scale simulations of ductile failure micromechanisms in nanocrystalline Cu at high strain rates. Phys Rev B 80:104108

Dongare AM, Rajendran AM, LaMattina B, Zikry MA, Brenner DW (2010) Atomic scale studies of spall behavior in nanocrystalline Cu. J Appl Phys 108:113518

Mackenchery K, Valisetty RR, Namburu RR, Stukowski A, Rajendran AM, Dongare AM (2016) Dislocation evolution and peak spall strengths in single crystal and nanocrystalline Cu. J Appl Phys 119:044301

Agarwal G, Dongare AM (2016) Shock wave propagation and spall failure in single crystal Mg at atomic scales. J Appl Phys 119:145901

Weng SY, Ning HM, Hu N et al (2016) Strengthening effects of twin interface in Cu/Ni multilayer thin films–a molecular dynamics study. Mater Des 111:1–8

Zhang RF, Germann TC, Wang J et al (2013) Role of interface structure on the plastic response of Cu/Nb nanolaminates under shock compression: non-equilibrium molecular dynamics simulations. Scripta Mater 68:114–117

Zhang RF, Germann TC, Liu XY et al (2014) Layer size effect on the shock compression behavior of fcc–bcc nanolaminates. Acta Mater 79:74–48

Fensin SJ, Valone SM, Cerreta EK et al (2015) Nucleation and evolution of dynamic damage at Cu/Pb interfaces using molecular dynamics. AIP Conf Proc 1793:070017

Dongare AM, Zhigilei LV, Rajendran AM, LaMattina B (2009) Interatomic potentials for atomic scale modeling of metal-matrix ceramic particle reinforced nanocomposites. Compos Part B Eng 40:461–467

Dongare AM, Neurock M, Zhigilei LV (2009) A new angular-dependent embedded atom method potential for atomistic simulations of metal-covalent systems. Phys Rev B 80:184106–184113

Dongare AM, LaMattina B, Irving DL, Rajendran AM, Zikry MA, Brenner DW (2012) An angular-dependent embedded atom method (a-eam) interatomic potential to model thermodynamic and mechanical behavior of Al/Si composite materials. Model Simul Mater Sci Eng 20:035007. https://doi.org/10.1088/0965-0393/20/3/035007

Dongare AM, LaMattina B, Rajendran AM (2012) Strengthening behavior and tension-compression strength–asymmetry in nanocrystalline metal-ceramic composites. J Eng Mater Technol 134:041003

Frolov T, Darling KA, Kecskes LJ, Mishin Y (2012) Stabilization and strengthening of nanocrystalline copper by alloying with tantalum. Acta Mater 60:2158–2168

Chen J, Tschopp MA, Dongare AM, Shock wave propagation and spall failure of nanocrystalline Cu/Ta alloys: effect of ta in solid-solution. J Appl Phys (submitted, in review)

Plimpton S (1995) Fast parallel algorithms for short-range molecular dynamics. J Comput Phys 117:1–19

Mishin Y, Mehl MJ, Papaconstantopoulos DA (2001) Structural stability and lattice defects in copper: ab initio, tight-binding, and embedded-atom calculations. Phys Rev B 63:224106

Pun GPP, Darling KA, Kecskes LJ, Mishin Y (2015) Angular-dependent interatomic potential for the Cu–Ta system and its application to structural stability of nano-crystalline alloys. Acta Mater 100:377–391

Stukowski A (2014) Computational analysis methods in atomistic modeling of crystals. JOM 66:399–407

Derlet PM, Swygenhoven HV (2003) Atomic positional disorder in fcc metal nanocrystalline grain boundaries. Phys Rev B 67:014202

Stukowski A, Albe K (2010) Extracting dislocations and non-dislocation crystal defects from atomistic simulation data. Modell Simul Mater Sci Eng 18:085001

Stukowski A, Bulatov VV, Arsenlis A (2012) Automated identification and indexing of dislocations in crystal interfaces. Modell Simul Mater Sci Eng 20:085007

Bhatia MA, Rajagopalan M, Darling KA et al (2017) The role of Ta on twinnability in nanocrystalline Cu–Ta alloys. Mater Res Lett 5:48–54

Dongare AM (2014) Quasi-coarse-grained dynamics: modeling of metallic materials at mesoscales. Phil Mag 94:3877–3897

Agarwal G, Dongare AM (2017) Modeling the thermodynamic behavior and shock response of Ti systems at the atomic scales and the mesoscales. J Mater Sci 52:10853–10870. https://doi.org/10.1007/s10853-017-1243-y

Agarwal G, Valisetty RR, Namburu R, Rajendran AM, Dongare AM (2017) The quasi-coarse-grained dynamics method to unravel the mesoscale evolution of defects/damage during shock loading and spall failure of polycrystalline al microstructures. Sci Rep 7:12376

Acknowledgements

This material is based upon work supported by the National Science Foundation (NSF) CMMI Grant-1454547.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All the authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Chen, J., Tschopp, M.A. & Dongare, A.M. Role of nanoscale Cu/Ta interfaces on the shock compression and spall failure of nanocrystalline Cu/Ta systems at the atomic scales. J Mater Sci 53, 5745–5765 (2018). https://doi.org/10.1007/s10853-017-1879-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1879-7