Abstract

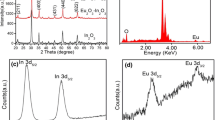

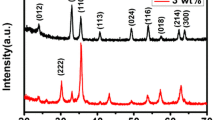

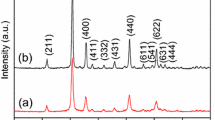

Pure and Ho-doped In2O3 nanotubes (NTs) and porous nanotubes (PNTs) were successfully synthesized by conventional electrospinning process and the following calcination at different temperatures. X-ray diffractometry (XRD), thermogravimetric analysis (TGA), Raman spectrometer, energy-dispersive spectroscopy, scanning and transmission electron microscopy were carefully used to investigate the morphologies, structures and chemical compositions of these samples. Their sensing properties toward ethanol gas were studied. Compared with pure In2O3 NTs (response value is 17), pure In2O3 PNTs (response value is 20) demonstrated enhanced sensing characteristics. What’s more, the response of Ho-doped In2O3 PNTs sensors to 100 ppm ethanol was up to 60 at 240 °C, which increased three times more than that of the pure In2O3 PNTs. Additionally, the minimum concentration for ethanol was 200 ppb (response value is 2). The increased gas-sensing ability was attributed not only to the hollow and porous structure, but to the Ho dopant. Furthermore, Ho-doped In2O3 PNTs enable sensor to discriminate between ethanol and the other gas distinctly, particularly acetone that is usually indistinguishable from ethanol. Also, by analyzing XRD, TGA and Raman spectrometer, a possible formation mechanism of porous nanotubes and sensing mechanism were put forward.

Similar content being viewed by others

References

Guo L, Shen X, Zhu G, Chen K (2011) Sens Actuators B Chem 155:752. https://doi.org/10.1016/j.snb.2011.01.042

Wagner T, Haffer S, Weinberger C, Klaus D, Tiemann M (2013) Chem Soc Rev 42:4036. https://doi.org/10.1039/C2CS35379B

Katoch A, Abideen ZU, Kim J-H, Kim SS (2016) Sens Actuators B Chem 232:698. https://doi.org/10.1016/j.snb.2016.04.013

Katoch A, Choi S-W, Kim SS (2014) Nanotechnology 25:455504. https://doi.org/10.1088/0957-4484/25/45/455504

Espinosa EH, Ionescu R, Bittencourt C et al (2007) Thin Solid Films 515:8322. https://doi.org/10.1016/j.tsf.2007.03.017

Kaniyoor A, Imran Jafri R, Arockiadoss T, Ramaprabhu S (2009) Nanoscale 1:382. https://doi.org/10.1039/b9nr00015a

Qian LH, Wang K, Li Y, Fang HT, Lu QH, Ma XL (2006) Mater Chem Phys 100:82. https://doi.org/10.1016/j.matchemphys.2005.12.009

Feng C, Li W, Li C et al (2012) Sens Actuators B Chem 166–167:83. https://doi.org/10.1016/j.snb.2011.12.083

Okamoto A, Shibasaki I (2003) J Cryst Growth 251:560. https://doi.org/10.1016/S0022-0248(02)02448-X

Bloor LG, Manzi J, Binions R et al (2012) Chem Mater 24:2864. https://doi.org/10.1021/cm300596c

Chikhale LP, Patil JY, Rajgure AV, Shaikh FI, Mulla IS, Suryavanshi SS (2014) Ceram Int 40:2179. https://doi.org/10.1016/j.ceramint.2013.07.136

Habibzadeh S, Khodadadi AA, Mortazavi Y (2010) Sens Actuators B Chem 144:131. https://doi.org/10.1016/j.snb.2009.10.047

Qin W, Xu L, Song J, Xing R, Song H (2013) Sens Actuators B Chem 185:231. https://doi.org/10.1016/j.snb.2013.05.001

Che G, Lakshmi BB, Martin CR, Fisher ER, Ruoff RS (1998) Chem Mater 10:260

Tao X, Sun L, Li Z, Zhao Y (2009) Nanoscale Res Lett 5:383. https://doi.org/10.1007/s11671-009-9493-5

Lakshmi BB, Patrissi CJ, Martin CR (1997) Chem Mater 9:2544. https://doi.org/10.1021/cm970268y

Xu L, Song H, Dong B, Wang Y, Chen J, Bai X (2010) Inorg Chem 49:10590. https://doi.org/10.1021/ic101602a

Xu L, Dong B, Wang Y, Bai X, Liu Q, Song H (2010) Sens Actuators B Chem 147:531. https://doi.org/10.1016/j.snb.2010.04.003

Huang Z-M, Zhang YZ, Kotaki M, Ramakrishna S (2003) Compos Sci Technol 63:2223. https://doi.org/10.1016/S0266-3538(03)00178-7

Azhari SJ, Diab MA (1998) Polym Degrad Stab 60:253. https://doi.org/10.1016/S0141-3910(97)00073-6

Chen W-S, Huang D-A, Chen H-C et al (2009) Cryst Growth Des 9:4070. https://doi.org/10.1021/cg900297q

Enhanced acetone sensing properties of Eu-In2O3 nanotubes with bumps (2016) Institution of Engineering and Technology, http://digital-library.theiet.org/content/journals/10.1049/mnl.2016.0235

Kumar M, Singh VN, Singh F, Lakshmi KV, Mehta BR, Singh JP (2008) Appl Phys Lett 92:171907. https://doi.org/10.1063/1.2910501

Olivia MB, Ariano DR, Cleocir JD, Alexandre JCL, Edson RL, Adenilson JC (2010) J Phys D Appl Phys 43:045401

Gan J, Lu X, Wu J et al (2013) Sci Rep 3:1021. https://doi.org/10.1038/srep01021

Dayal P, Kyu T (2006) J Appl Phys 100:043512

Cho JS, Kang YC (2015) Small 11:4673

Tu KN, Gösele U (2005) Appl Phys Lett 86:093111

Yanping L, Zhihong L, Yuhu L, Zhiyong L, Qihou L (2014) Chin J Nonferrous Metals 24:221

Shaalan NM, Rashad M, Abdel-Rahim MA (2016) Mater Sci Semicond Process 56:260. https://doi.org/10.1016/j.mssp.2016.09.007

Lim SK, Hwang S-H, Chang D, Kim S (2010) Sens Actuators B Chem 149:28. https://doi.org/10.1016/j.snb.2010.06.039

Gao L, Cheng Z, Xiang Q, Zhang Y, Xu J (2015) Sens Actuators B Chem 208:436. https://doi.org/10.1016/j.snb.2014.11.053

Zhang L-h, Wang S-l, Liu F-h (2015) J Electron Mater 44:3408. https://doi.org/10.1007/s11664-015-3905-3

Guo X, Zhang J, Ni M, Liu L, Lian H, Wang H (2016) J Mater Sci Mater Electron 27:11262. https://doi.org/10.1007/s10854-016-5247-1

Yu F, Wu Y, Ma J, Zhang C (2013) J Environ Sci 25:195. https://doi.org/10.1016/S1001-0742(12)60023-0

Zhao C, Zhang G, Han W et al (2013) Cryst Eng Commun 15:6491. https://doi.org/10.1039/C3CE40962G

Bagheri M, Khodadadi AA, Mahjoub AR, Mortazavi Y (2015) Sens Actuators B Chem 220:590. https://doi.org/10.1016/j.snb.2015.06.007

Anand K, Kaur J, Singh RC, Thangaraj R (2017) Chem Phys Lett 670:37. https://doi.org/10.1016/j.cplett.2016.12.057

Montazeri A, Jamali-Sheini F (2017) Sens Actuators B Chem 242:778. https://doi.org/10.1016/j.snb.2016.09.181

Navale ST, Bandgar DK, Nalage SR et al (2013) Ceram Int 39:6453. https://doi.org/10.1016/j.ceramint.2013.01.074

Sun P, Cai Y, Du S et al (2013) Sens Actuators B Chem 182:336. https://doi.org/10.1016/j.snb.2013.03.019

Franke ME, Koplin TJ, Simon U (2006) Small 2:36. https://doi.org/10.1002/smll.200500261

Singh S, Singh A, Yadav BC, Dwivedi PK (2013) Sens Actuators B Chem 177:730. https://doi.org/10.1016/j.snb.2012.11.096

Hamedani NF, Mahjoub AR, Khodadadi AA, Mortazavi Y (2012) Sens Actuators B Chem 169:67. https://doi.org/10.1016/j.snb.2012.02.074

Miller DR, Akbar SA, Morris PA (2014) Sens Actuators B Chem 204:250. https://doi.org/10.1016/j.snb.2014.07.074

Anand K, Kaur J, Singh RC, Thangaraj R (2016) Ceram Int 42:10957. https://doi.org/10.1016/j.ceramint.2016.03.233

An W, Wu X, Zeng XC (2008) J Phys Chem C 112:5747. https://doi.org/10.1021/jp711105d

Cheng JP, Wang BB, Zhao MG, Liu F, Zhang XB (2014) Sens Actuators B Chem 190:78. https://doi.org/10.1016/j.snb.2013.08.098

Belmonte JC, Manzano J, Arbiol J et al (2006) Sens Actuators B Chem 114:881. https://doi.org/10.1016/j.snb.2005.08.007

Prabhu E, Gnanasekar KI, Ravindran TR, Jayaraman V, Gnanasekaran T (2014) J Electrochem Soc 161:B176. https://doi.org/10.1149/2.0451409jes

Acknowledgements

The work has been supported by the Jilin Provincial Science and Technology Department (No. 20170101199JC).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Duan, H., Wang, Y., Li, S. et al. Controllable synthesis of Ho-doped In2O3 porous nanotubes by electrospinning and their application as an ethanol gas sensor. J Mater Sci 53, 3267–3279 (2018). https://doi.org/10.1007/s10853-017-1796-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1796-9