Abstract

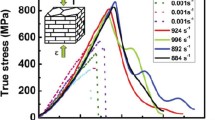

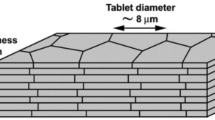

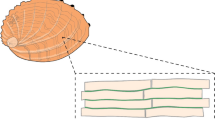

The aim of this study is to examine the response of Pinctada maxima shell to drilling predation, focusing on the underlying protective mechanisms. The shell exhibits a self-assembled smart architecture with a highly multilayered structure. The outer layer is composed of a prismatic structure, and the inner nacreous layer consists of several sub-layers that contain normal brick-like platelets and unique convex lens-like platelets, with myostracal layers laying in between them. Such a smart architecture provides several fundamental protective mechanisms against drilling penetration. First, the occurrence of multiple microcracking and the deformability of platelets in the nacre structure with brick-like platelets can effectively lock the damage locally during drilling penetration. Second, a few myostracal layers embedded within the nacre structure as a disguise of fresh body may induce the driller to inject the toxic salivary secretions, thus protecting the platelets at the bottom of the hole. Third, a new type of platelets with a convex lens-like shape is observed for the first time to be positioned in the internal part of the shell. This layer can effectively prevent the final attack due to its remarkable plastic deformation capacity or bendability via converting a part of tensile stresses into compressive stresses through interfacial sliding and rotation among the convex lens-like platelets. The findings of the present study can pave the way for the development of bioinspired advanced engineering structures with superior protectability against the penetration.

Similar content being viewed by others

References

Li L, Ortiz C (2014) Pervasive nanoscale deformation twinning as a catalyst for efficient energy dissipation in a bioceramic armour. Nat Mater 13:501–507

Weaver JC, Milliron GW, Miserez A et al (2012) The stomatopod dactyl club: a formidable damage-tolerant biological hammer. Science 336:1275–1280

Humburg H, Volkmann E, Koch D et al (2014) Combination of biological mechanisms for a concept study of a fracture-tolerant bio-inspired ceramic composite material. J Mater Sci 49:8040–8050. doi: https://doi.org/10.1007/s10853-014-8511-x

Vermeij GJ (1995) A natural history of shells. Princeton University Press, Princeton

Sun J, Bhushan B (2012) Hierarchical structure and mechanical properties of nacre: a review. RSC Adv 2:7617–7632

Jackson AP, Vincent JFV, Turner RM (1988) The mechanical design of nacre. Proc R Soc Lond B 234:415–440

Meyers MA, McKittrick J, Chen PY (2013) Structural biological materials: critical mechanics-materials connections. Science 339:773–779

Kakisawa H, Sumitomo T (2012) The toughening mechanism of nacre and structural materials inspired by nacre. Sci Tech Adv Mater 12:064710

Katti DR, Katti KS (2001) Modeling microarchitecture and mechanical behavior of nacre using 3D finite element techniques. J Mater Sci 36:1411–1417. doi: https://doi.org/10.1023/A:1017528209162

Metzler RA, Jones JA, D’Addario AJ et al (2017) Polarimetry of Pinctada fucata nacre indicates myostracal layer interrupts nacre structure. R Soc Open Sci 4:160893

Gao P, Liao Z, Wang X et al (2015) Layer-by-layer proteomic analysis of Mytilus galloprovincialis shell. PLoS ONE 10:e0133913

Liao Z, Bao L, Fan M et al (2015) In-depth proteomic analysis of nacre, prism, and myostracum of Mytilus shell. J Proteomics 122:26–40

Lopez MI, Martinez PEM, Meyers MA (2014) Organic interlamellar layers, mesolayers and mineral nanobridges: contribution to strength in abalone (Haliotis rufescence) nacre. Acta Biomater 10:2056–2064

Glover EA, Taylor JD (2016) Pleurolucina from the western Atlantic and eastern Pacific Oceans: a new intertidal species from Curaçao with unusual shell microstructure (Mollusca, Bivalvia, Lucinidae). Zookeys 620:1–19

Morris JP, Wang Y, Backeljau T et al (2016) Biomimetic and bio-inspired uses of mollusc shells. Margenom 27:85–90

Barthelat F, Tang H, Zavattieri PD et al (2007) On the mechanics of mother-of-pearl: a key feature in the material hierarchical structure. J Mech Phys Solids 55:306–337

Ji HM, Li XW, Chen DL (2017) Cymbiola nobilis shell: toughening mechanisms in a crossed-lamellar structure. Sci Rep 7:40043

Ji HM, Li XW (2014) Microstructural characteristic and its relation to mechanical properties of Clinocardium californiense shell. J Am Ceram Soc 97:3991–3998

Ji HM, Jiang Y, Yang W et al (2015) Biological self-arrangement of fiber like aragonite and its effect on mechanical behavior of Veined rapa whelk shell. J Am Ceram Soc 98:3319–3325

Li XW, Ji HM, Yang W et al (2017) Mechanical properties of cross-lamellar structures in biological shells: a review. J Mech Behav Biomed Mater 74:54–71

Pahari A, Mondal S, Bardhan S et al (2016) Subaerial naticid gastropod drilling predation by Natica tigrina on the intertidal molluscan community of Chandipur, Eastern Coast of India. Palaeogeogr Palaeoclimatol Palaeoecol 451:110–123

Das A, Mondal S, Bardhan S (2014) A note on exceptionally high confamilial naticid drilling frequency on Natica gualteriana from the Indian subcontinent. Hist Biol 26:758–764

Bromley RG (1981) Concepts in ichnotaxonomy illustrated by small round holes in shells. Acta Geol Hisp 16:55–64

Kabat AR (1990) Predatory ecology of naticid gastropods with a review of shell boring. Malacologia 32:155–193

Suzuki M, Saruwatari K, Kogure T et al (2009) An acidic matrix protein, Pif, is a key macromolecule for nacre formation. Science 325:1388–1390

Steer MA, Semmens JM (2003) Pulling or drilling, does size or species matter? An experimental study of prey handing in Octopus dierythraeus (Norman, 1992). J Exp Mar Biol Ecol 290:165–178

Wang RZ, Suo Z, Evans AG et al (2001) Deformation mechanisms in nacre. J Mater Res 16:2485–2493

Song F, Soh AK, Bai YL (2003) Structural and mechanical properties of the organic matrix layers of nacre. Biomaterials 24:3623–3631

Evans AG, Suo Z, Wang RZ et al (2001) Model for the robust mechanical behavior of nacre. J Mater Res 16:2475–2484

Lin AYM, Chen PY, Meyers MA (2008) The growth of nacre in the abalone shell. Acta Biomater 4:131–138

Li X, Chang WC, Chao YJ et al (2004) Nanoscale structural and mechanical characterization of a natural nanocomposite material: the shell of red abalone. Nano Lett 4:613–617

Li X, Huang Z (2009) Unveiling the formation mechanism of pseudo-single-crystal aragonite platelets in nacre. Phy Rev Lett 102:075502

Huang Z, Li X (2012) Order-disorder transition of aragonite nanoparticles in nacre. Phy Rev Lett 109:025501

Zhang G, Li X (2012) Uncovering aragonite nanoparticle self-assembly in nacre: a natural armor. Cryst Grow Des 12:4306–4310

Huang Z, Pan Z, Li H et al (2014) Hidden energy dissipation mechanism in nacre. J Mater Res 29:1573–1578

Huang Z, Li H, Pan Z et al (2011) Uncovering high-strain rate protection mechanism in nacre. Sci Rep 1:148

Liu J, Huang Z, Pan Z et al (2017) Atomistic origin of deformation twinning in biomineral aragonite. Phys Rev Lett 118:105501

Katti KS, Katti DR, Pradhan SM, Bhosle A (2005) Platelet interlocks are the key to toughness and strength in nacre. J Mater Res 20:1097–1100

Katti KS, Katti DR (2006) Why is nacre so tough and strong? Mater Sci Eng C 26:1317–1324

Barthelat F, Tang H, Zavattieri PD et al (2007) On the mechanics of mother-of-pearl: a key feature in the material hierarchical structure. J Mech Phys Solids 55:306–337

Xu ZH, Li X (2011) Deformation strengthening of biopolymer in nacre. Adv Funct Mater 21:3883–3888

Li X, Xu ZH, Wang R (2006) In situ observation of nanograin rotation and deformation in nacre. Nano Lett 6:2301–2304

Yang W, Liu Q, Yue Z et al (2017) Rotation of hard particles in a soft matrix. J Mech Phys Solids 101:285–310

Acknowledgements

This work was supported by the Fundamental Research Funds for the Central Universities of China under Grant No. N150506002. This work was also partially supported by National Natural Science Foundation of China (Grant Nos. 51571058 and 51231002). D. L. Chen is grateful for the financial support by the Premier’s Research Excellence Award (PREA), NSERC-Discovery Accelerator Supplement (DAS) Award, Canada Foundation for Innovation (CFI), and Ryerson Research Chair (RRC) program. The authors would also like to thank Messrs. Q. Li, C. Ma, A. Machin, J. Amankrah, and R. Churaman for easy access to the laboratory facilities of Ryerson University and their assistance in the experiments.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

No potential conflict of interest was reported by the authors.

Rights and permissions

About this article

Cite this article

Ji, H.M., Liang, S.M., Li, X.W. et al. A self-assembled smart architecture against drilling predation in a Pinctada maxima shell: protective mechanisms. J Mater Sci 53, 3417–3426 (2018). https://doi.org/10.1007/s10853-017-1782-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1782-2