Abstract

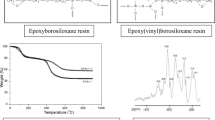

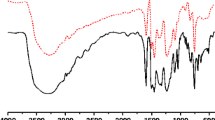

Realization of easily processable, tough phenolic functional polymer materials is of high demand for composite applications. Herein, we report the synthesis of boron-containing phenolic–siloxane hybrid polymers through a facile copper-catalysed azide–alkyne click chemistry (CuAAC) approach. For this, phenolic resoles incorporated with boron (PFB) was propargyl-derivatized and then bridged through triazole moieties using telechelic α, ω azidated polydimethylsiloxane (AZ-PDMS). The propargylated boronated PF (PFBPr) resins exhibited high heat of reaction during thermal cure due to the prevalence of multiple reactions. PFBPr-siloxane hybrid co-polymers exhibited glass transitions in the ranges – 100 to – 75 °C and at 25–35 °C corresponding to soft segment and hard segments. Pyrolysed PFBPr-siloxane products showed mixed phase heterogeneous systems of B and SiC. Introduction of boron and silicon improved the degree of graphitization and reduced the graphite crystallite size of the carbonization products. The pyrolysed compounds of silicon and boron formed during high temperature were conducive for creating a layer of void-free graphitic ordered carbon that improved with boron and silicon content, as revealed by SEM images.

Similar content being viewed by others

References

John B et al (2011) Medium-density ablative composites: processing, characterisation and thermal response under moderate atmospheric re-entry heating conditions. J Mater Sci 46(15):5017–5021

Pulci G et al (2010) Carbon–phenolic ablative materials for re-entry space vehicles: manufacturing and properties. Compos A 41(10):1483–1490

Patton RD et al (2002) Ablation, mechanical and thermal conductivity properties of vapor grown carbon fiber/phenolic matrix composites. Compos A 33(2):243–251

Bahramian AR et al (2006) Ablation and thermal degradation behaviour of a composite based on resol type phenolic resin: process modeling and experimental. Polymer 47(10):3661–3673

Natali M et al (2012) Ablative properties of carbon black and MWNT/phenolic composites: a comparative study. Compos A 43(1):174–182

Nair CPR (2004) Advances in addition-cure phenolic resins. Prog Polym Sci 29(5):401–498

Bindu RL et al (2001) Addition-cure phenolic resins based on propargyl ether functional novolacs: synthesis, curing and properties. Polym Int 50(6):651–658

Martín C et al (2006) Boron-containing novolac resins as flame retardant materials. Polym Degrad Stab 91(4):747–754

Abdalla MO, Ludwick A, Mitchell T (2003) Boron-modified phenolic resins for high performance applications. Polymer 44(24):7353–7359

Liu Y et al (2002) Thermal properties and stability of boron-containing phenol-formaldehyde resin formed from paraformaldehyde. P Polym Degrad Stab 77(3):495–501

Gao J et al (2004) Structure of a boron-containing bisphenol-F formaldehyde resin and kinetics of its thermal degradation. Polym Degrad Stab 83(1):71–77

Wang D-C et al (2008) Preparation and thermal stability of boron-containing phenolic resin/clay nanocomposites. Polym Degrad Stab 93(1):125–133

Chiang C-L et al (2004) Synthesis, characterization, thermal properties and flame retardance of novel phenolic resin/silica nanocomposites. Polym Degrad Stab 83(2):207–214

Zhang Y et al (2006) Phenolic resin–trisilanolphenyl polyhedral oligomeric silsesquioxane (POSS) hybrid nanocomposites: structure and properties. Polymer 47(9):2984–2996

Zhuo D et al (2011) Flame retardancy materials based on a novel fully end-capped hyperbranched polysiloxane and bismaleimide/diallylbisphenol A resin with simultaneously improved integrated performance. J Mater Chem 21(18):6584–6594

Wu YH et al (2013) Hybrid nanocomposites based on novolac resin and octa (phenethyl) polyhedral oligomeric silsesquioxanes (POSS): miscibility, specific interactions and thermomechanical properties. Polym Bull (Berlin) 70(12):3261–3277

Li S et al (2017) Polysiloxane modified phenolic resin with co-continuous structure. Polymer 120(1):217–222

Li S et al (2016) Structure and improved thermal stability of phenolic resin containing silicon and boron elements. Polym Degrad Stab 133(1):321–329

Pittman CU et al (2003) Hybrid inorganic/organic crosslinked resins containing polyhedral oligomeric silsesquioxanes. Macromol Symp 196(1):301–325

Pittman CU et al (2006) Chemical Bonding between phenolic resins and polyhedral oligomeric silsesquioxanes (POSS) in inorganic–organic hybrid nanocomposites. J Inorg Organomet Polym Mater 16(1):43–59

Kolb HC et al (2001) Click chemistry: diverse chemical function from a few good reactions. Angew Chem Int Ed 40(11):2004–2021

Moses JE et al (2007) The growing applications of click chemistry. Chem Soc Rev 36(8):1249–1262

Hoyle CE et al (2010) Thiol–ene click chemistry. Angew Chem Int Ed 49(9):1540–1573

Binder WH, Sachsenhofer R (2007) ‘Click’chemistry in polymer and materials science. Macromol Rapid Commun 28(1):15–54

John B et al (2007) Low-density phenolic syntactic foams: processing and properties. Cell Polym 26(4):229–244

Madsen et al (2013) Novel cross-linkers for PDMS networks for controlled and well distributed grafting of functionalities by click chemistry. Polym Chem 4(5):1700–1707

Ganesh Babu T, Devasia R (2016) Boron-modified phenol formaldehyde resin-based self-healing matrix for Cf/SiBOC composites. Adv Appl Ceram 115(8):457–469

Zmihorska-Gotfryd A (2006) Phenol-formaldehyde resols modified by boric acid. Polimery 5:386–388

Kawamoto AM et al (2010) Synthesis of a boron modified phenolic resin. J Aerosp Technol Manag 2(2):169–182

Novikov N et al (1986) Analysis of the 13C and 1H NMR spectra of phenol-formaldehyde resole oligomers. Polym Sci USSR 28(5):1187–1196

Nair CR et al (2001) Thermal characteristics of addition-cure phenolic resins. Polym Degrad Stab 73(2):251–257

Grenier-Loustalot M et al (1997) Prepolymers with propargylic terminal residues—I. Simulation of reaction mechanisms and kinetics on monofunctional models. Eur Polym J 33(7):1125–1134

Li S et al (2015) Enhanced compatibility and morphology evolution of the hybrids involving phenolic resin and silicone intermediate. Mater Chem Phys 165(1):25–33

Li H et al (2013) Thermal degradation behaviors of polydimethylsiloxane-graft-poly(methyl methacrylate). Thermochim Acta 573(1):32–38

Xu L et al (2012) Fabrication and microstructure of boron-doped isotropic pyrolytic carbon. Carbon 50(12):4705–4710

Lyu SC et al (2011) Synthesis of boron-doped double-walled carbon nanotubes by the catalytic decomposition of tetrahydrofuran and triisopropyl borate. Carbon 49(5):1532–1541

Li S et al (2016) The effect of structure on thermal stability and anti-oxidation mechanism of silicone modified phenolic resin. Polym Degrad Stab 124(1):68–76

Cuesta A et al (1994) Raman microprobe studies on carbon materials. Carbon 32(8):1523–1532

Babu TG, Devasia R (2016) Boron modified phenol formaldehyde derived Cf/SiBOC composites with improved mechanical strength for high temperature applications. J Inorg Organomet Polym Mater 26(4):764–772

Wang S et al (2014) High char yield of aryl boron-containing phenolic resins: the effect of phenylboronic acid on the thermal stability and carbonization of phenolic resins. Polym Degrad Stab 99(1):1–11

Liu Y, Jing X (2007) Pyrolysis and structure of hyperbranched polyborate modified phenolic resins. Carbon 45(10):1965–1971

Shi F et al (2010) A new route to fabricate SiB 4 modified C/SiC composites. J Eur Ceram Soc 30(9):1955–1962

Ko T-H et al (2001) Microstructural changes of phenolic resin during pyrolysis. J Appl Polym Sci 81(5):1084–1089

Milonjić S, Bibić N (1995) Influence of boric acid concentration on silicon carbide morphology. J Mater Sci Lett 14(15):1052–1054

WU Y et al (2001) Direct observation of vapor–liquid–solid nanowire growth. J Am Chem Soc 123(13):3156–3166

Acknowledgements

The authors acknowledge Director, VSSC for permission to publish this work. Analytical support from the Analytical and Spectroscopy Division, VSSC, and Ceramic Matrix Products Division, VSSC, is also acknowledged.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors hereby declare that there is no conflict of interest for this manuscript preparation and publishing.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Chandran, M.S., Sunitha, K., Gayathri, D.S. et al. Boron-containing phenolic–siloxane hybrid polymers through facile click chemistry route. J Mater Sci 53, 2497–2510 (2018). https://doi.org/10.1007/s10853-017-1737-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1737-7