Abstract

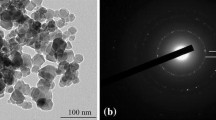

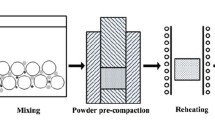

A novel in situ core–shell-structured Ti@(Al–Si–Ti) particulate-reinforced A356 composite was synthesized via powder thixoforming. It is noted that there is a significant improvement in toughness of the particulate-reinforced Al matrix composites, and the problems related to fabrication techniques were also solved. The effects of reheating duration at a semisolid temperature of 600 °C on the microstructure and tensile properties of the resulting composites were investigated. The results indicated that a thick, compact Al–Si–Ti intermetallic shell formed around the Ti powders when the reheating time was at 50 min. A composite containing these reinforcing particles exhibited good tensile properties. Its ultimate tensile strength and yield strength (YS) were decreased by only 2.1 and 3.5%, respectively, while its elongation was increased by 167.8% and up to 8.3%, compared to the (Al, Si)3Tip/A356 composite that was thixoformed after the Ti powders had completely reacted. This occurred because the core–shell-structured particles with hard, compact shells exhibited strengthening role comparable to that provided by the monolithic (Al, Si)3Ti intermetallic particles, and the Ti core effectively inhibited or delayed crack propagation by blunting crack tips and severe plastic deformation. In addition, a modified shear lag model that incorporated the indirect strengthening mechanisms and varying shell thicknesses of Al–Si–Ti intermetallics was proposed to successfully predict the YS of the composites.

Similar content being viewed by others

References

Surappa MK (2003) Aluminium matrix composites: challenges and opportunities. Sādhanā 28:319–334

Wang X, Jha A, Brydson R (2004) In situ fabrication of Al3Ti particle reinforced aluminium alloy metal–matrix composites. Mater Sci Eng, A 364:339–345

Torralba JM, Velasco F, Costa CE, Vergara I, Cáceres D (2002) Mechanical behaviour of the interphase between matrix and reinforcement of Al 2014 matrix composites reinforced with (Ni3Al)p. Compos Part A 33:427–434

Kumar PRS, Kumaran S, Rao TS, Sivaprasad K (2002) Microstructures and mechanical properties of Al3Fe reinforced aluminum matrix composites fabricated by a plasma synthesis method. Mater Trans 43:2487–2493

Wang SH, Kao PW, Chang CP (1999) The strengthening effect of Al3Ti in ultrafine grained Al–Al3Ti alloys. Scr Mater 40:289–295

Lei Y, Liu Z, Xue H, Hu W, Chen X, Yan J (2012) Microstructure features of in-situ SiCp/6061Al in plasma arc welding by new reinforced phase. J Mater Eng 37:55–60 (in Chinese)

Jie W, Kandalova EG, Zhang RJ, Nikitin VI (2000) Al3Ti/Al composites prepared by SHS. Rare Met Mater Eng 29:145–148

Xu H, Jian X, Meek TT, Han Q (2004) Degassing of molten aluminum A356 alloy using ultrasonic vibration. Mater Lett 58:3669–3673

Tzamtzis S, Barekar NS, Babu NH, Patel J, Dhindaw BK, Fan Z (2009) Processing of advanced Al/SiC particulate metal matrix composites under intensive shearing—a novel Rheo-process. Compos Part A 40:144–151

Deepak Kumar S, Mandal A, Chakraborty M (2015) On the age hardening behavior of thixoformed A356-5TiB2 in situ composite. Mater Sci Eng, A 636:254–262

Deepak Kumar S, Mandal A, Chakraborty M (2015) Effect of Thixoforming on the microstructure and tensile properties of A356 alloy and A356-5TiB2 in situ composite. Trans Indian Inst Met 68(Suppl 2):123–130

Li PB, Chen TJ, Qin H (2016) Effects of mold temperature on the microstructure and tensile properties of SiCp/2024 Al-based composites fabricated via powder thixoforming. Mater Des 112:34–45

Zhang XZ, Chen TJ, Qin YH (2016) Effects of solution treatment on tensile properties and strengthening mechanisms of SiCp/6061Al composites fabricated by powder thixoforming. Mater Des 99:182–192

Li P, Chen T, Zhang S, Guan R (2015) Research on semisolid microstructural evolution of 2024 aluminum alloy prepared by powder thixoforming. Metals 5:547–564

Cao Y, Guo C, Zhu S, Wei N, Javed RA, Jiang F (2015) Fracture behavior of Ti/Al3Ti metal-intermetallic laminate (MIL) composite under dynamic loading. Mater Sci Eng, A 637:235–242

Qin Y, Chen T, Wang Y, Zhang X, Li P (2016) Semisolid microstructural evolution during partial remelting of a bulk alloy prepared by cold pressing of the Ti–Al–2024Al powder mixture. Materials 9:199

Wang YJ, Chen TJ, Zhang SQ, Qin YH, Zhang XZ (2016) Effects of partial remelting on microstructure of Al–Si–Ti bulk alloy prepared by cold pressing mixed powders. Mater Trans 57:1124–1133

Wang Y, Song M, Ni S, Xue Y (2014) In situ formed core–shell structured particle reinforced aluminum matrix composites. Mater Des 56:405–408

Peng LM, Wang JH, Li H, Zhao JH, He LH (2005) Synthesis and microstructural characterization of Ti–Al3Ti metal-intermetallic laminate (MIL) composites. Scr Mater 52:243–248

Li J (2010) Effect of Si in alloy on intermetallic compounds growth behavior during reaction between solid Ti and liquid Al. Master Dissertation, Harbin Institute of Technology

Gao T, Li PT, Li YG, Liu XF (2011) Influence of Si and Ti contents on the microstructure, microhardness and performance of TiAlSi intermetallics in Al–Si–Ti alloys. J Alloy Compd 509:8013–8017

Zhao YH, Zhou JE (2002) Aluminum matrix composite reinforced by in situ formed intermetallic Al3Ti. Trans Nonferrous Met Soc China 12:643–648

Hong SJ, Kim HM, Huh D, Suryanarayana C, Chun BS (2003) Effect of clustering on the mechanical properties of SiC particulate-reinforced aluminum alloy 2024 metal matrix composites. Mater Sci Eng, A 347:198–204

Chen YS, Chen TJ (2015) Effects of processing parameters on microstructure and mechanical properties of powder-thixoforged 6061 aluminum alloy. Trans Nonferrous Met Soc China 25:699–712

Chen TJ, Hao Y, Li YD (2007) Effects of processing parameters on microstructure of thixoformed ZA27 alloy. Mater Des 28:1279–1287

Wang Z, Tan J, Sun BA, Scudino S, Prashanth KG, Zhang WW, Li YY, Eckert J (2014) Fabrication and mechanical properties of Al-based metal matrix composites reinforced with Mg65Cu20Zn5Y10 metallic glass particles. Mater Sci Eng, A 600:53–58

Zheng R, Yang H, Liu T, Ameyama K, Ma C (2014) Microstructure and mechanical properties of aluminum alloy matrix composites reinforced with Fe-based metallic glass particles. Mater Des 53:512–518

Zhang Q, Xiao BL, Wang WG, Ma ZY (2012) Reactive mechanism and mechanical properties of in situ composites fabricated from an Al–TiO2 system by friction stir processing. Acta Mater 60:7090–7103

Wang Z, Prashanth KG, Scudino S, Chaubey AK, Sordelet DJ, Zhang WW, Li YY, Eckert J (2014) Tensile properties of Al matrix composites reinforced with in situ devitrified Al84Gd6Ni7Co3 glassy particles. J Alloys Compd 586:S419–S422

Poirier D, Drew RAL, Trudeau ML, Gauvin R (2010) Fabrication and properties of mechanically milled alumina/aluminum nanocomposites. Mater Sci Eng, A 527:7605–7614

Li PB, Chen TJ, Zhang SQ (2017) Effects of reheating time on microstructure and tensile properties of SiCp/2024 Al-based composites fabricated using powder thixoforming. Met Mater Int 23:193–201

Sekine H, Chent R (1995) A combined microstructure strengthening analysis of SiCp/Al metal matrix composites. Composites 26:183–188

Liu G, Sun J, Nan CW, Chen KH (2005) Experiment and multiscale modeling of the coupled influence of constituents and precipitates on the ductile fracture of heat-treatable aluminum alloys. Acta Mater 53:3459–3468

Arsenault RJ, Shi N (1986) Dislocation generation due to differences between the coefficients of thermal expansion. Mater Sci Eng 81:175–187

Tjong SC, Ma ZY (2000) Microstructural and mechanical characteristics of in situ metal matrix composites. Mater Sci Eng R 29:49–113

Li G, Wang H (2010) Microstructure of in situ Al3Ti/6351Al composites fabricated with electromagnetic stirring and fluxes. Trans Nonferrous Met Soc China 20:577–583

Tong XC, Ghosh AK (2001) Fabrication of in situ TiC reinforced aluminum matrix composites. J Mater Sci 36:4059–4069

Liu B, Huang L, Lin G (2015) Elastic and plastic behaviors of laminated Ti-TiBw/Ti composites. J Wuhan Uni Technol-Mater Sci Ed 30:596–600

Acknowledgements

The authors wish to express thanks to financial support from the National Natural Science Foundation of China (Grant No. 51564035) and the Program for Hongliu Outstanding Talents of Lanzhou University of Technology.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, T.J., Qin, H. & Zhang, X.Z. Effects of reheating duration on the microstructure and tensile properties of in situ core–shell-structured particle-reinforced A356 composites fabricated via powder thixoforming. J Mater Sci 53, 2576–2593 (2018). https://doi.org/10.1007/s10853-017-1713-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1713-2