Abstract

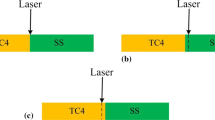

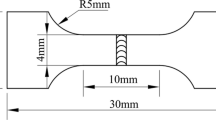

Pulsed laser welding of Ti alloy to stainless steel (SS) has been applied using pure V as an interlayer. Microstructures and mechanical properties of joints were improved by changing laser offset. Two-pass welding was applied, and two weld zones were produced in the joint. The unmelted V interlayer acted as a barrier to mixing of the two base materials during welding. The melting amount of base materials and V interlayer was controlled by changing laser offset to control the fusion ratio and thus to improve joint microstructure. σ-Phase was present in V–SS weld zone of joint with laser offset of zero, which resulted in failure of the joint. Through changing laser offset, V concentration in V–SS weld zone of SS-0.2 mm offset joint was decreased and σ-phase was eliminated in the joint. ω-Phase was discovered in Ti alloy–V weld zone of zero-offset joint, which had an adverse effect on mechanical property of the joint. Through changing laser offset, V concentration in Ti alloy–V weld zone of V-0.2 mm offset joint was increased and precipitation of ω-phase was prevented. Three joints (zero-offset joint, SS-0.2 mm offset joint and V-0.2 mm offset joint) exhibited the tensile strength of 504, 548 and 599 MPa, respectively.

Similar content being viewed by others

References

He P, Zhang JH, Zhou RL, Li XQ (1999) Diffusion bonding technology of a titanium alloy to a stainless steel web with a Ni interlayer. Mater Charact 43:287–292

Wei YH, Dong ZB, Liu B (2011) Stress distributions of welding joints in Ti–steel composite pressure vessel under working conditions. Sci Technol Weld Join 16:709–716

Ghosh M, Chatterjee S, Mishra B (2003) The effect of intermetallics on the strength properties of diffusion bonds formed between Ti–5.5Al–2.4V and 304 stainless steel. Mater Sci Eng A 363:268–274

Murray JL (1987) Phase diagrams of binary titanium alloys. ASM, International, Novelty, pp 99–111

Akbari Mousavi SAA, Sartangi PF (2008) Effect of post-weld heat treatment on the interface microstructure of explosively welded titanium–stainless steel composite. Mater Sci Eng A 494:329–336

Chen S, Zhang M, Huang J (2014) Microstructures and mechanical property of laser butt welding of titanium alloy to stainless steel. Mater Des 53:504–511

Kundu S, Ghosh M, Laik A, Bhanumuthy K, Kale GB, Chatterjee S (2005) Diffusion bonding of commercially pure titanium to 304 stainless steel using copper interlayer. Mater Sci Eng A 407:154–160

Denga YQ, Shenga GM, Huanga ZH (2013) Microstructure and mechanical properties of diffusion bonded titanium/304 stainless steel joint with pure Ag interlayer. Sci Technol weld Join 18:143–146

Kundu S, Chatterjee S (2008) Characterization of diffusion bonded joint between titanium and 304 stainless steel using a Ni interlayer. Mater Charact 5:631–637

He P, Yue H, Zhan JH (2008) Hot pressing diffusion bonding of a titanium alloy to a stainless steel with an aluminum alloy interlayer. Mater Sci Eng A 486:171–176

Yue X, He P, Feng JC, Zhang JH, Zhu FQ (2008) Microstructure and interfacial reactions of vacuum brazing titanium alloy to stainless steel using an AgCuTi filler metal. Mater Charact 59:1721–1727

Dong H, Yang Z, Wang Z, Deng D, Dong C (2014) Vacuum brazing TC4 titanium alloy to 304 stainless steel with Cu–Ti–Ni–Zr–V amorphous alloy foil. JMEPEG 23:3770–3777

Luo Z, Wang G, Xie G, Wang L, Zhao K (2013) Interfacial microstructure and properties of a vacuum hot roll-bonded titanium–stainless steel clad plate with a Nb interlayer. Acta Metall Sin 26:754–760

Akbari Mousavi SAA, Farhadi Sartangi P (2009) Experimental investigation of explosive welding of cp-titanium/AISI 304 stainless steel. Mater Des 30:459–468

Song J, Kostka A, Veehmayer M, Raabe D (2011) Hierarchical microstructure of explosive joints: example of titanium to steel cladding. Mater Sci Eng A 528:2641–2647

Fazel-Najafabadi M, Kashani-Bozorg SF, Zarei-Hanzaki A (2010) Joining of CP-Ti to 304 stainless steel using friction stir welding technique. Mater Des 31:4800–4807

Fazel-Najafabadi M, Kashani-Bozorg SF, Zarei-Hanzaki A (2011) Dissimilar lap joining of 304 stainless steel to CP-Ti employing friction stir welding. Mater Des 32:1824–1832

Cheepu MM, Muthupandi V, Loganathan S (2012) Friction welding of titanium to 304 stainless steel with electroplated nickel interlayer. Mater Sci Forum 710:620–625

Chen HC, Bi GJ, Lee BY, Cheng CK (2016) Laser welding of CP Ti to stainless steel with different temporal pulse shapes. J Mater Process Technol 231:58–65

Wang T, Zhang B, Feng J, Tang Q (2012) Effect of a copper filler metal on the microstructure and mechanical properties of electron beam welded titanium–stainless steel joint. Mater Charact 73:104–113

Ting W, Zhang BG, Chen GQ, Feng JC, Qi TANG (2010) Electron beam welding of Ti-15-3 titanium alloy to 304 stainless steel with copper interlayer sheet. Trans Nonferrous Met Soc China 20:1829–1834

Tomashchuk I, Sallamand P, Belyavina N, Pilloz M (2013) Evolution of microstructures and mechanical properties during dissimilar electron beam welding of titanium alloy to stainless steel via copper interlayer. Mater Sci Eng A 585:114–122

Zhang Y, Sun DQ, Gu XY, Liu YJ (2017) Nd/YAG pulsed laser welding of TC4 titanium alloy to 301L stainless steel via pure copper interlayer. Int J Adv Manuf Technol 90:953–961

Wang T, Zhang BG, Feng J (2014) Influences of different filler metals on electron beam welding of Ti alloy to stainless steel. T Nonferr Metal Soc 24:108–114

Tomashchuk I, Sallamand P, Andrzejewski H, Grevey D (2011) The formation of intermetallics in dissimilar Ti6Al4V/copper/AISI 316L electron beam and Nd: YAG laser joints. Intermetallics 19:1466–1473

Gao M, Mei SW, Wang ZM, Li XY, Zeng XY (2012) Characterisation of laser welded dissimilar Ti/steel joint using Mg interlayer. Sci Technol Weld Join 17:269–276

Li HM, Sun DQ, Cai XL, Dong P, Wang WQ (2012) Laser welding of TiNi shape memory alloy and stainless steel using Ni interlayer. Mater Des 39:285–293

Li H, Sun D, Cai X, Dong P, Gu X (2013) Laser welding of TiNi shape memory alloy and stainless steel using Co filler metal. Opt Laser Technol 45:453–460

Elrefaey A, Tillmann W (2009) Solid state diffusion bonding of Ti to steel using a copper base alloy as interlayer. J Mater Process Technol 209:2746–2752

Liu DY, Zhou C, Cong LJ, Liu SC (2014) Microstructure and mechanical properties of diffusion bonded joints between Ti and low carbon steel with copper interlayer. Met Sci Heat Treat 33:105–110

Gao M, Chen C, Wang L (2015) Laser-arc hybrid welding of dissimilar titanium alloy and stainless steel using copper wire. Mater Sci Eng A 46:2007–2020

Okamoto H (2002) J Phase Equilib 26:549–550

Bo H, Duarte LI, Zhu WJ, Liu LB, Liu HS, Jina ZP, Leinenbach C (2013) Experimental study and thermodynamic assessment of the Cu–Fe–Ti system. Calphad 40:24–33

Zhang Y, Sun D, Gu X, Li H (2016) A hybrid joint based on two kinds of bonding mechanisms for Titanium alloy and stainless steel by pulsed laser welding. Mater Lett 185:152–155

Oliveira JP, Panton B, Zeng Z, Andrei CM, Zhou Y, Miranda RM, Braz Fernandes FM (2016) Laser joining of NiTi to Ti6Al4V using a Nb interlayer. Acta Mater 105:9–15

Okamoto H (1993) Ti–V (Titanium–Vanadium). J Phase Equilib 14:266–267

Murray JL (1981) The Ti–V (Titanium–Vanadium) system. Bull Alloy Phase Diagr 2:48–55

Okamoto H (2006) Fe–V(Iron–Vanadium). J Phase Equilib 27:542–543

Chu Q, Zhang M, Li J, Yan C, Qin Z (2017) Influence of vanadium filler on the properties of titanium and steel TIG welded joints. J Mater Process Technol 240:293–304

Tomashchuk I, Grevey D, Sallamand P (2015) Dissimilar laser welding of AISI 316L stainless steel to Ti6–Al4–6V alloy via vanadium interlayer. Mater Sci Eng A 622:37–45

Anawa EM, Olabi AG (2008) Control of welding residual stress for dissimilar laser welded materials. J Mater Process Technol 204:22–33

Pardal G, Ganguly S, Williams S, Vaja J (2016) Dissimilar metal joining of stainless steel and titanium using copper as transition metal. Int J Adv Manuf Technol 86:1139–1150

Shanmugarajan B, Padmanabham G (2012) Fusion welding studies using laser on Ti–SS dissimilar combination. Opt Laser Eng 50:1621–1627

Banerjee S, Mukhopadhyay P (2004) Phase transformations: examples from titanium and zirconium alloys, 1st edn. Pergamon Press, Oxford

Ohmuri Y, Ogo T, Nakai K, Kobayashi S (2001) Effects of ω-phase precipitation on β/α, α′ transformations in a metastable β titanium alloy. Mater Sci Eng A 312:182–188

Dutta J, Ananthakrishna G, Banerjee S (2012) On the athermal nature of the β to ω transformation. Acta Mater 60:556–564

Mccabe KK, Sass SL (1971) The initial stages of the omega phase transformation in Ti–V alloys. Philos Mag 23:957–970

Ghosh C, Basu J, Ramachandran D, Mohandas E (2016) Phase separation and ω transformation in binary V–Ti and ternary V–Ti–Cr alloys. Acta Mater 121:310–324

Sukedai E, Liu W, Awaji M, Horiuchi T (1994) Investigation of atomic structure of ω-phase crystals in Ti–Mo alloy using high resolution electron microscopy. Ultramicroscopy 54:192–200

Sukedai E, Kitano Y, Ohnishi A (1997) Investigation of initial structures of aged ω-phase crystals in β-titanium alloys using high resolution electron microscopy. Micron 28:269–277

Ustinovshikov Y, Pushkarev B, Sapegina I (2005) Phase transformations in alloys of the Fe–V system. J Alloys Compd 398:133–138

Cieslak J, Tobola J, Dubiel SM (2013) Formation energy in σ-phase Fe–V alloys. J Phys Chem Solids 74:1303–1307

Guo CP, Li CR, Zheng X, Du ZM (2012) Thermodynamic modeling of the Fe–Ti–V system. CALPHAD 38:155–160

Bowen AW (1971) Scr Mater 5:709–716

Williams JC, Hickman BS, Marcus HL (1971) Metall Trans 2:1913–1919

Nogami S, Miyazaki J, Hasegawa A, Nagasaka T, Muroga T (2013) Study on electron beam weld joints between pure vanadium and SUS316L stainless steel. J Nucl Mater 442:562–566

Min XH, Emura S, Zhang L, Tsuzaki K, Tsuchiya K (2015) Improvement of strength–ductility tradeoff in β titanium alloy through pre-strain induced twins combined with brittle ω phase. Mater Sci Eng A 646:279–287

Hon Y-H, Wang J-Y, Pan Y-N (2003) Composition/phase structure and properties of Titanium–Niobium alloys. Mater Trans JIM 44:2384–2390

Ramsteiner IB, Shchyglo O, Mezger M, Udyansky A, Bugaev V, Schoder S, Reichert H, Dosch H (2008) Omega like diffuse x-ray scattering in Ti–V caused by static lattice distortion. Acta Mater 56:1298–1305

Sikka SK, Vohra YK, Chidambaram R (1982) Omega phase in materials. Prog Mater Sci 27:245–310

Ng HP, Devaraj A, Nag S, Bettles CJ, Gibson M, Fraser HL, Muddle BC, Banerjee R (2011) Phase separation and formation of omega phase in the beta matrix of a Ti–V–Cu alloy. Acta Mater 59:2981–2991

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, Y., Sun, D., Gu, X. et al. Microstructure and mechanical property improvement of dissimilar metal joints for TC4 Ti alloy to 301L stainless steel. J Mater Sci 53, 2942–2955 (2018). https://doi.org/10.1007/s10853-017-1708-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1708-z