Abstract

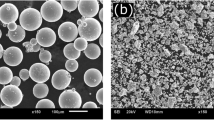

A simple and cost-effective method for the synthesis of a porous Al scaffold has been optimised using only NaAlH4 and TiCl3. The starting materials were compacted into a pellet and sintered under dynamic vacuum to remove the Na and H2. The sintering conditions, such as vacuum level, temperature, and time, were the key factors that influenced both the extraction of Na and H2 from the pellet and the overall porosity. Quantitative phase analysis by X-ray diffraction revealed that after the sintering process, the as-prepared porous Al scaffold consisted primarily of Al. Morphological observations conducted by scanning electron microscopy showed that the scaffold exhibited an open network of pores with a small number of mesopores and no formation of micropores. The specific surface area of the scaffold was determined to be 7.9 ± 0.1 and 6.0 ± 0.5 m2/g by the Brunauer–Emmet–Teller method and from small-angle X-ray scattering measurements, respectively. The total porosity of the Al scaffold was 44.6%.

Similar content being viewed by others

References

Yazdimamaghani M, Razavi M, Vashaee D, Moharamzadeh K, Boccaccini AR, Tayebi L (2017) Porous magnesium-based scaffolds for tissue engineering. Mater Sci Eng, C 71:1253–1266

Jiang G, Li Q, Wang C, Dong J, He G (2016) Characterization and investigation of the deformation behavior of porous magnesium scaffolds with entangled architectured pore channels. J Mech Behav Biomed Mater 64:139–150

Gasparotto L, Prowald A, Borisenko N, El Abedin SZ, Garsuch A, Endres F (2011) Electrochemical synthesis of macroporous aluminium films and their behavior towards lithium deposition/stripping. J Power Sources 196(5):2879–2883

Thepkaew J, Therdthianwong S, Kucernak A, Therdthianwong A (2012) Electrocatalytic activity of mesoporous binary/ternary PtSn-based catalysts for ethanol oxidation. J Electroanal Chem 685:41–46

Wang H, Wang L, Sato T, Sakamoto Y, Tominaka S, Miyasaka K, Miyamoto N, Nemoto Y, Terasaki O, Yamauchi Y (2012) Synthesis of mesoporous Pt films with tunable pore sizes from aqueous surfactant solutions. Chem Mater 24(9):1591–1598

Sofianos MV, Sheppard DA, Ianni E, Humphries TD, Rowles MR, Liu S, Buckley CE (2017) Novel synthesis of porous aluminium and its application in hydrogen storage. J Alloys Compd 702:309–317

Sofianos MV, Sheppard DA, Rowles MR, Humphries TD, Liu S, Buckley CE (2017) Novel synthesis of porous Mg scaffold as a reactive containment vessel for LiBH 4. RSC Adv 7(58):36340–36350

Zhang J, Liu W (2011) Thin porous metal sheet-supported NaA zeolite membrane for water/ethanol separation. J Membr Sci 371(1):197–210

Jiang G, He G (2014) A new approach to the fabrication of porous magnesium with well-controlled 3D pore structure for orthopedic applications. Mater Sci Eng, C 43:317–320

Kirkland N, Kolbeinsson I, Woodfield T, Dias G, Staiger M (2011) Synthesis and properties of topologically ordered porous magnesium. Mater Sci Eng, B 176(20):1666–1672

Seyedraoufi Z, Mirdamadi S (2013) Synthesis, microstructure and mechanical properties of porous Mg-Zn scaffolds. J Mech Behav Biomed Mater 21:1–8

Nakajima H (2010) Fabrication, properties, and applications of porous metals with directional pores. Proc Jpn Acad, Ser B 86(9):884–899

Ding Y, Kim YJ, Erlebacher J (2004) Nanoporous gold leaf:“Ancient technology”/advanced material. Adv Mater 16(21):1897–1900

Wirtz M, Parker M, Kobayashi Y, Martin CR (2002) Molecular sieving and sensing with gold nanotube membranes. Chem Rec 2(4):259–267

Chou D-T, Hong D, Saha P, Ferrero J, Lee B, Tan Z, Dong Z, Kumta PN (2013) In vitro and in vivo corrosion, cytocompatibility and mechanical properties of biodegradable Mg–Y–Ca–Zr alloys as implant materials. Acta Biomater 9(10):8518–8533

Niederlaender J, Walter M, Krajewski S, Schweizer E, Post M, Schille C, Geis-Gerstorfer J, Wendel HP (2014) Cytocompatibility evaluation of different biodegradable magnesium alloys with human mesenchymal stem cells. J Mater Sci Mater Med 25(3):835–843

Lee J-W, Han H-S, Han K-J, Park J, Jeon H, Ok M-R, Seok H-K, Ahn J-P, Lee KE, Lee D-H (2016) Long-term clinical study and multiscale analysis of in vivo biodegradation mechanism of Mg alloy. Proc Natl Acad Sci 113(3):716–721

Levine B (2008) A new era in porous metals: applications in orthopaedics. Adv Eng Mater 10(9):788–792

Li Q, Bjerrum NJ (2002) Aluminum as anode for energy storage and conversion: a review. J Power Sources 110(1):1–10

Winter M, Besenhard JO (1999) Electrochemical lithiation of tin and tin-based intermetallics and composites. Electrochim Acta 45(1):31–50

Chumphongphan S, Filsø U, Paskevicius M, Sheppard DA, Jensen TR, Buckley CE (2014) Nanoconfinement degradation in NaAlH4/CMK-1. Int J Hydrogen Energy 39(21):11103–11109

Javadian P, Sheppard DA, Buckley CE, Jensen TR (2015) Hydrogen storage properties of nanoconfined LiBH 4–Ca (BH 4) 2. Nano Energy 11:96–103

Javadian P, Sheppard DA, Buckley CE, Jensen TR (2015) Hydrogen storage properties of nanoconfined LiBH 4–NaBH 4. Int J Hydrogen Energy 40(43):14916–14924

Paskevicius M, Tian H-Y, Sheppard DA, Webb CJ, Pitt MP, Gray EM, Kirby NM, Buckley CE (2011) Magnesium hydride formation within carbon aerogel. J Phys Chem C 115(5):1757–1766

Tian H-Y, Buckley C, Mule S, Paskevicius M, Dhal B (2008) Preparation, microstructure and hydrogen sorption properties of nanoporous carbon aerogels under ambient drying. Nanotechnology 19(47):475605

Tian H-Y, Buckley C, Paskevicius M, Sheppard D (2012) Hydrogen storage in carbon aerogels. In: Terranova ML, Orlanducci S, Rossi M (eds) Carbon nanomaterials for gas adsorption. Pan Stanford Publishing, Singapore, pp 131–160

Tian H-Y, Buckley C, Sheppard D, Paskevicius M, Hanna N (2010) A synthesis method for cobalt doped carbon aerogels with high surface area and their hydrogen storage properties. Int J Hydrogen Energy 35(24):13242–13246

Paskevicius M, Jepsen LH, Schouwink P, Černý R, Ravnsbæk DB, Filinchuk Y, Dornheim M, Besenbacher F, Jensen TR (2017) Metal borohydrides and derivatives–synthesis, structure and properties. Chem Soc Rev 46(5):1565–1634

Chaudhary A-L, Paskevicius M, Sheppard DA, Buckley CE (2015) Thermodynamic destabilisation of MgH2 and NaMgH3 using Group IV elements Si, Ge or Sn. J Alloys Compd 623:109–116

Paskevicius M, Sheppard DA, Buckley CE (2010) Thermodynamic changes in mechanochemically synthesized magnesium hydride nanoparticles. J Am Chem Soc 132:5077–5083

Meggouh M, Grant D, Walker G (2011) Optimizing the destabilization of LiBH4 for hydrogen storage and the effect of different Al sources. J Phys Chem C 115(44):22054–22061

Kulinowski KM, Jiang P, Vaswani H, Colvin VL (2000) Porous metals from colloidal templates. Adv Mater 12(11):833–838

Malgras V, Ataee-Esfahani H, Wang H, Jiang B, Li C, Wu KCW, Kim JH, Yamauchi Y (2016) Nanoarchitectures for mesoporous metals. Adv Mater 28(6):993–1010

Gross KJ, Carrington KR, Barcelo S, Karkamkar A, Purewal J, Zhou HC, Shengqian M, Dantzer P, Ott K, Burrell T, Semeslberger T, Pivak Y, Dam B, Chandra D (2012) Recommended Best Practices for the Characterization of Storage Properties of Hydrogen Storage Materials; V3.34 Feb. 21, p. 263. Accessed 12/08/2017 https://energy.gov/sites/prod/files/2014/03/f12/best_practices_hydrogen_storage.pdf

Rietveld H (1969) A profile refinement method for nuclear and magnetic structures. J Appl Crystallogr 2(2):65–71

Hill R, Howard C (1987) Quantitative phase analysis from neutron powder diffraction data using the Rietveld method. J Appl Crystallogr 20(6):467–474

Bruker AXS (2014) TOPAS version 5

Sing KS (1985) Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (Recommendations 1984). Pure Appl Chem 57(4):603–619

Halsey G (1948) Physical adsorption on non-uniform surfaces. J Chem Phys 16(10):931–937

Harkins WD, Jura G (1944) Surfaces of solids. XII. An absolute method for the determination of the area of a finely divided crystalline solid. J Am Chem Soc 66(8):1362–1366

Zhdanov V, Fenelonov V, Efremov D (1987) Determination of pore-size distribution from sorption isotherms: application of percolation theory. J Colloid Interface Sci 120(1):218–223

Dreiss CA, Jack KS, Parker AP (2006) On the absolute calibration of bench-top small-angle X-ray scattering instruments: a comparison of different standard methods. J Appl Crystallogr 39(1):32–38

Australian Synchrotron (2017) Scatterbrain

Beaucage G (1995) Approximations leading to a unified exponential/power-law approach to small-angle scattering. J Appl Crystallogr 28(6):717–728

Ilavsky J, Jemian PR (2009) Irena: tool suite for modeling and analysis of small-angle scattering. J Appl Crystallogr 42(2):347–353

Spalla O, Lyonnard S, Testard F (2003) Analysis of the small-angle intensity scattered by a porous and granular medium. J Appl Crystallogr 36(2):338–347

Beaucage G (1996) Small-angle scattering from polymeric mass fractals of arbitrary mass-fractal dimension. J Appl Crystallogr 29(2):134–146

Besselink R, Stawski T, Van Driessche A, Benning L (2016) Not just fractal surfaces, but surface fractal aggregates: derivation of the expression for the structure factor and its applications. J Chem Phys 145(21):211908

Haiduc AG, Stil HA, Schwarz MA, Paulus P, Geerlings JJC (2005) On the fate of the Ti catalyst during hydrogen cycling of sodium alanate. J Alloys Compd 393(1–2):252–263

Liu Y, Zhang X, Wang K, Yang Y, Gao M, Pan H (2016) Achieving ambient temperature hydrogen storage in ultrafine nanocrystalline TiO 2@ C-doped NaAlH 4. J Mater Chem A 4(3):1087–1095

Humphries TD, Makepeace JW, Hino S, David B, Hauback BC (2014) Regeneration of Sodium Alanate studied by powder in situ neutron and synchrotron X-ray diffraction. J Mater Chem A 2(39):16594–16600

Balde CP, Stil HA, van der Eerden AMJ, de Jong KP, Bitter JH (2007) Active Ti species in TiCl3-doped NaAlH4. Mechanism for catalyst deactivation. J Phys Chem C 111:2797–2802

Bogdanović B, Schwickardi M (1997) Ti-doped alkali metal aluminium hydrides as potential novel reversible hydrogen storage materials. J Alloys Compd 253:1–9

Isobe S, Yao H, Wang Y, Kawasaki H, Hashimoto N, Ohnuki S (2010) Study on decomposition process of NaAlH4 by in situ TEM. Int J Hydrogen Energy 35 (Copyright (C) 2012 American Chemical Society (ACS). All Rights Reserved.):7563–7567

Brinks HW, Jensen CM, Srinivasan SS, Hauback BC, Blanchard D, Murphy K (2004) Synchrotron X-ray and neutron diffraction studies of NaAlH4 containing Ti additives. J Alloys Compd 376(1–2):215–221

Weidenthaler C, Pommerin A, Felderhoff M, Bogdanović B, Schüth F (2003) On the state of the titanium and zirconium in Ti- or Zr-doped NaAlH4 hydrogen storage material. Phys Chem Chem Phys 5(22):5149–5153

Banus DM, McSharry JJ, Sullivan EA (1955) Sodium-sodium hydride-hydrogen system at 500°–600°. J Am Chem Soc 77 (Copyright (C) 2012 American Chemical Society (ACS). All Rights Reserved.):2007–2010

Klostermeier W, Franck EU (1982) Liquid mixtures of sodium and sodium hydride at high pressures and temperatures. Berichte der Bunsen-Gesellschaft fuer Physikalische Chemie 86:606–612

Humphries TD, Sheppard DA, Rowles MR, Sofianos MV, Buckley CE (2016) Fluoride substitution in sodium hydride for thermal energy storage applications. J Mater Chem A 4(31):12170–12178

Banhart J (2001) Manufacture, characterisation and application of cellular metals and metal foams. Prog Mater Sci 46(6):559–632

Su F, Zhao X, Wang Y, Zeng J, Zhou Z, Lee JY (2005) Synthesis of graphitic ordered macroporous carbon with a three-dimensional interconnected pore structure for electrochemical applications. J Phys Chem B 109(43):20200–20206

Yan L, Bo X, Zhang Y, Guo L (2014) Facile green synthesis of nitrogen-doped porous carbon and its use for electrocatalysis towards nitrobenzene and hydrazine. Electrochim Acta 137:693–699

Zhao C, Wang W, Yu Z, Zhang H, Wang A, Yang Y (2010) Nano-CaCO 3 as template for preparation of disordered large mesoporous carbon with hierarchical porosities. J Mater Chem 20(5):976–980

Acknowledgements

The authors CEB, DAS, and MVS acknowledge the financial support of the Australian Research Council for ARC Discovery Grant DP150101708. The author DAS acknowledges the financial support of a Curtin University’s Postdoctoral Research Fellowship. The author EI acknowledges Curtin University for a Curtin University Postgraduate Scholarship. The authors acknowledge the facilities and technical assistance of the Microscopy & Microanalysis Facility of the John de Laeter Centre at Curtin University. CEB acknowledges the financial support of the Australian Research Council for ARC LIEF Grants LE0775551 and LE0989180 which enabled the XRD to be undertaken. This research was partially undertaken on the SAXS/WAXS beamline at the Australian Synchrotron, Victoria, Australia. The authors would like to thank Dr. Nigel Kirby, principal beamline scientist, for his assistance.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Ianni, E., Sofianos, M.V., Sheppard, D.A. et al. Synthesis and characterisation of a porous Al scaffold sintered from NaAlH4 . J Mater Sci 53, 1076–1087 (2018). https://doi.org/10.1007/s10853-017-1560-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1560-1