Abstract

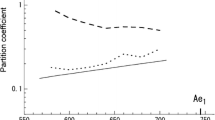

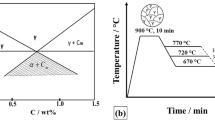

The pearlite-to-austenite transformation during isothermal and uniform heating processes of classic bearing steels was studied using a dilatometer. The relationship between ferrite, cementite, and austenite during the transformation was investigated in detail. To explain the experimental phenomenon more theoretically, pearlite-to-austenite transformation was simulated using the DICTRA module of the Thermo-Calc software package based on a simplified model. Experimental results validated the pearlite-to-austenite transformation mechanism of low-alloy steel previously proposed. The transformation is controlled by Cr diffusion and C diffusion below and above the partition-to-no-partition temperature, respectively.

Similar content being viewed by others

Notes

UHP EAF (EBT) + LF + VD: Ultra-high power electric furnace smelting (eccentric bottom tapping) + refined-smelting ladle furnace + vacuum degassing.

References

Hillert M (1962) The formation of pearlite. In: Zkay VF, Aaronson HI (eds) Decomposition of austenite by diffusional processes. Interscience, New York, pp 197–237

Lan YJ, Li DZ, Li YY (2004) Modeling austenite decomposition into ferrite at different cooling rate in low-carbon steel with cellular automation method. Acta Mater 52:1721–1729

Pandit AS, Bhadeshia HKDH (2011) Mixed diffusion-controlled growth of pearlite in binary steel. Proc R Soc A 467:508–521

Pandit AS, Bhadeshia HKDH (2011) Diffusion-controlled growth of pearlite in ternary steels. Proc R Soc A 467:2948–2961

Bastian KB, Kenny S, Thomas LC, Cathrine F (2016) Composition-dependent variation of magnetic properties and interstitial ordering in homogeneous expanded austenite. Acta Mater 106:32–39

Li ZX, Li CS, Zhang J, Li BZ, Pang XD (2016) Microstructure of hot rolled 1.0C–1.5Cr bearing steel and subsequent spheroidization annealing. Metall Mater Trans A 47:3607–3621

Warke VS, Sisson RD, Makhlouf MM (2009) A model for converting dilatometric strain measurements to the fraction of phase formed during the transformation of austenite to martensite in powder metallurgy steels. Metall Mater Trans A 40:569–572

Andrés CGD, Caballero FG, Capdevila C, Bhadeshia HKDH (1998) Modelling of kinetics and dilatometric behavior of non-isothermal pearlite-to-austenite transformation in an eutectoid steel. Scr Mater 39:791–796

Martín DS, Rivera-Díaz-del-Castillo PEJ, García-de-Andrés C (2008) In situ study of austenite formation by dilatometry in a low carbon microalloyed steel. Scr Mater 58:926–929

Andrés CGD, Caballero FG, Capdevila C (1998) Dilatometric characterization of pearlite dissolution in 0.1C–0.5Mn low carbon low manganese steel. Scr Mater 38:1835–1842

Lee SJ, Clarke KD, Tyne CJV (2010) An on-heating dilation conversional model for austenite formation in hypoeutectoid steels. Metall Mater Trans A 41:2224–2235

Lee SJ, Clarke KD (2010) A conversional model for austenite formation in hypereutectoid steels. Metall Mater Trans A 41:3027–3031

Onink M, Brakrnan CM, Tichelaar FD, Mittemeijer EJ, Zwaag SVD (1993) The lattice parameters of austenite and ferrite in Fe–C alloys as functions of carbon concentration and temperature. Scr Metall Mater 29:1011–1016

Onink M, Tichelaar FD, Brakman CM, Mittemeijer EJ, Zwaag SVD (1996) Quantitative analysis of the dilatation by decomposition of Fe–C austenites: calculation of volume change upon transformation. Z Metall 87:24–32

Li CM, Mittemeijer EJ, Sommer F (2000) Quantitative dilatometric analysis of the isothermal decomposition of Fe–C austenite. Z Metall 91:5–9

Li CM, Sommer F, Mittemeijer EJ (2001) Quantitative dilatometric analysis of the isothermal decomposition of hypereutectoid Fe–C austenite. Z Metall 92:32–36

Kop TA, Sietsma J, Zwaag SVD (2001) Dilatometric analysis of phase transformations in hypo-eutectoid steels. J Mater Sci 36:519–526. doi:10.1023/A:1004805402404

Lee SJ, Clarke KD (2015) A quantitative investigation of cementite dissolution kinetics for continuous heating of hypereutectoid steel. Metall Mater Trans A 46:3917–3923

Miyamoto G, Usuki H, Li ZD, Furuhara T (2010) Effects of Mn, Si and Cr addition on reverse transformation at 1073 K from spheroidized cementite structure in Fe–0.6 mass% C alloy. Acta Mater 58:4492–4502

Karmazin L, Krejčí J (1994) The dependence of the austenitization kinetics on the type of initial spheroidized structure in low alloy steel. Mater Sci Eng A 185:L5–L7

Hillert M, Nilsson K, Törndahl LE (1971) Effect of alloying elements on the formation of austenite and dissolution of cementite. J Iron Steel Inst 209:49–66

Yang ZN, Xia Y, Enomoto M, Zhang C, Yang ZG (2016) Effect of alloying element partition in pearlite on the growth of austenite in high-carbon low alloy steel. Metall Mater Trans A 47:1019–1027

Li P, Li J, Meng Q, Hua W, Xu D (2013) Effect of heating rate on ferrite recrystallization and austenite formation of cold-roll dual phase steel. J Alloys Compd 578:320–327

Vázquez-Gómez O, Barrera-Godínez JA, Vergara-Hernández HJ (2015) Kinetic study of austenite formation during continuous heating of unalloyed ductile iron. Int J Min Metall Mater 22:27–31

Oliveira FLG, Andrade MS, Cota AB (2007) Kinetics of austenite formation during continuous heating in a low carbon steel. Mater Charact 58:256–261

Liu G, Li J, Zhang S, Wang J, Meng Q (2016) Dilatometric study on the recrystallization and austenization behavior of cold-rolled steel with different heating rates. J Alloys Compd 666:309–316

Martín DS, Cock TD, Junceda AG, Caballero FG, Capdevila C, Andrés CGD (2008) Effect of heating rate on reaustenitisation of low carbon niobium microalloyed steel. Mater Sci Technol 24:266–272

Huang J, Poole WJ, Militzer M (2004) Austenite formation during intercritical annealing. Metall Mater Trans A 35:3363–3375

Chea JY, Jang JH, Zhang GH, Kim KH, Lee JS, Bhadeshia HKDH, Suh DW (2011) Dilatometric analysis of cementite dissolution in hypereutectoid steels containing Cr. Scr Mater 65:245–248

Caballero FG, Capdevila C, Andres CGD (2002) Modelling of kinetics and dilatometric behaviour of austenite formation in a low-carbon steel with a ferrite plus pearlite initial microstructure. J Mater Sci 37:3533–3540. doi:10.1023/A:1016579510723

Shtansky DV, Nakai K, Ohmori Y (1999) Pearlite to austenite transformation in an Fe–2.6 Cr–1 C alloy. Acta Mater 47:2619–2632

Esin VA, Denand B, Bihan QL, Dehmas M, Teixeira J, Geandier G, Denis S, Sourmail T, Aeby-Gautier E (2014) In situ synchrotron X-ray diffraction and dilatometric study of austenite formation in a multi-component steel: influence of initial microstructure and heating rate. Acta Mater 80:118–131

Orlich J, Pietrzeniuk HJ (1976) Atlas zur Warmebehandlung der Stahle, 4, part 2. Verlag Stahleisen M.B.H, Dusseldorf

Rodel J, Spies HJ (1996) Modelling of austenite formation during rapid heating. Surf Eng 12:313–318

Hillert M (2002) Critical limit for massive transformation. Metall Mater Trans A 33:2299–2308

Schmidt ED, Damm EB, Sridhar S (2007) A study of diffusion- and interface-controlled migration of the austenite/ferrite front during austenitization of a case-hardenable alloy steel. Metall Mater Trans A 38:244–260

Andersson JO, Helander T, Höglund L, Shi PF, Sundman B (2002) Thermo-calc and DICTRA, computational tools for materials science. Calphad 26:273–312

Schneider A, Inden G (2005) Simulation of the kinetics of precipitation reactions in ferritic steels. Acta Mater 53:519–531

Liu F, Sommer F, Bos C, Mittemeijer EJ (2007) Analysis of solid state phase transformation kinetics: models and recipes. Int Mater Rev 52:193–212

Liu YC, Wang DJ, Sommer F, Mittemeijer EJ (2008) Isothermal austenite–ferrite transformation of Fe–0.04 at.% C alloy: dilatometric measurement and kinetic analysis. Acta Mater 56:3833–3842

Xia Y, Enomoto M, Yang ZG, Li ZD, Zhang C (2013) Effects of alloying elements on the kinetics of austenitization from pearlite in Fe–C–M alloys. Phil Mag 93:1095–1109

Chance J, Ridley N (1981) Chromium partitioning during isothermal transformation of a eutectoid steel. Metall Trans A 12:1205–1213

Acknowledgements

This work was supported by the National Natural Science Foundation of China (No. 51276015).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Z., Wen, Z., Su, F. et al. Dilatometric research on pearlite-to-austenite transformation of Fe–1C–1.44Cr low-alloy steel. J Mater Sci 53, 1424–1436 (2018). https://doi.org/10.1007/s10853-017-1556-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1556-x