Abstract

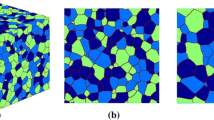

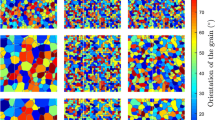

The coarsening behavior of three-phase materials, such as eutectic alloys, is of high technological interest. In this study, 3D ternary three-phase polycrystalline materials were modeled to study the effect of bulk diffusion and phase arrangement on the coarsening kinetics. The diffusion mobilities were defined to be different in the three phases. By varying the phase boundary and grain boundary energies, microstructures with different phase arrangements were obtained, in which the different types of grains had a tendency to alternate or cluster. In all cases, a regime was reached where the average grain size follows a power growth law with growth exponent \(n=3\), indicating bulk diffusion-controlled coarsening. The overall growth rate and that of the individual phases were clearly affected by the phase arrangement, the magnitude of the phase boundary energy and the diffusion mobilities of the different phases. In all cases, the phase with the lowest diffusion mobility showed the highest growth rate and on average a larger number of grain faces. While the average number of grain faces became constant in time in systems with constant grain boundary energy, the average number of grain faces continued to increase during the whole simulation time when the grain boundary energy was misorientation dependent.

Similar content being viewed by others

References

Ohnuma I, Ishida K, Nishizawa T (1999) Computer simulation of grain growth in dual-phase structures. Philos Mag A Phys Condens Matter Struct Defects Mech Prop 79:1131–1144

Fan D, Chen LQ (1997) Computer simulation of grain growth and Ostwald ripening in alumina–zirconia two-phase composites. J Am Ceram Soc 80:1773–1780

Fan D, Chen LQ (1997) Diffusion-controlled grain growth in two-phase solids. Acta Mater 45:3297–3310

Fan D, Chen LQ (1997) Topological evolution during coupled grain growth and Ostwald ripening in volume-conserved 2-D two-phase polycrystals. Acta Mater 45:4145–4154

Fan D, Chen LQ (1997) Grain growth and microstructural evolution in a two-dimensional two-phase solid containing only quadrijunctions. Scr Mater 37:233–238

Fan D, Chen SP, Chen LQ, Voorhees PW (2002) Phase-field simulation of 2-D Ostwald ripening in the high volume fraction regime. Acta Mater 50:1895–1907

Poulsen SO, Voorhees PW, Lauridsen EM (2013) Three-dimensional simulations of microstructural evolution in polycrystalline dual-phase materials with constant volume fractions. Acta Mater 61:1220–1228

Kim SG (2007) Large-scale three-dimensional simulation of Ostwald ripening. Acta Mater 55:6513

Streitenberger P (2013) Analytical description of phase coarsening at high volume fractions. Acta Mater 61:5026–5035

Yadav V, Vanherpe L, Moelans N (2016) Effect of volume fractions on microstructure evolution in isotropic volume-conserved two-phase alloys: a phase-field study. Comput Mater Sci 125:297–308

Poulsen SO, Voorhees PW (2016) Early stage phase separation in ternary alloys: a test of continuum simulations. Acta Mater 113:98–108

Ravash H, Vleugels J, Moelans N (2014) Three-dimensional phase-field simulation of microstructural evolution in three-phase materials with different diffusivities. J Mater Sci 49:7066–7072. doi:10.1007/s10853-014-8411-0

Sheng G, Wang T, Du Q, Wang KG, Liu ZK, Chen LQ (2010) Coarsening kinetics of a two phase mixture with highly disparate diffusion mobility. Commun Comput Phys 8:249–264

Chang K, Moelans N (2014) Effect of grain boundary energy anisotropy on highly textured grain structures studied by phase-field simulations. Acta Mater 64:443–454

Chang K, Chen LQ, Krill CE, Moelans N (2017) Effect of strong nonuniformity in grain boundary energy on 3-D grain growth behavior: a phase-field simulation study. Comput Mater Sci 127:67–77

Holm E, Srolovitz D, Cahn J (1993) Microstructural evolution in two-dimensional two-phase polycrystals. Acta Metall Mater 41:1119–1136

Moelans N, Blanpain B, Wollants P (2008) Quantitative analysis of grain boundary properties in a generalized phase field model for grain growth in anisotropic systems. Phys Rev B 78:024113

Folch R, Plapp M (2005) Quantitative phase-field modeling of two-phase growth. Phys Rev E 72:011602

Moelans N (2011) A quantitative and thermodynamically consistent phase-field interpolation function for multi-phase system. Acta Mater 59:1077

Andersson JQ, Ågren J (1992) Models for numerical treatment of multicomponent diffusion in simple phases. J Appl Phys 72:1350

Vanherpe L, Moelans N, Blanpain B, Vandewalle S (2011) Bounding box framework for efficient phase-field simulation of grain growth in anisotropic systems. Comput Mater Sci 50:2221

Vanherpe L, Moelans N, Blanpain B, Vandewalle S (2007) Bounding box algorithm for three-dimensional phase-field simulations of microstructural evolution in polycrystalline materials. Phys Rev E 76:056702

Olmsted DL, Foiles SM, Holm EA (2009) Survey of computed grain boundary properties in face-centered cubic metals: I. Grain boundary energy. Acta Mater 57:3694–3703

Moelans N, Wendler F, Nestler B (2009) Comparative study of two phase-field models for grain growth. Comput Mater Sci 46:479–490

Hosford WF, Brien J, House J, Angelis RD (2000) Use of ODF data to quantitatively describe fiber textures. Adv X-Ray Anal 42:502–509

Bollman W (1970) Crystal defects and crystalline interfaces. Springer, Berlin

Kamachali RD, Steinbach I (2012) 3-D phase-field simulation of grain growth; topological analysis versus mean-field approximations. Acta Mater 60:2719

Zollner D, Streitenberger P (2006) Three-dimensional normal grain growth: Monte Carlo Potts model simulation and analytical mean field theory. Scr Mater 54:1697

Rowenhorst D, Lewis A, Spanos G (2010) Three-dimensional analysis of grain topology and interface curvature in a b-titanium alloy. Acta Mater 58:5511–5519

Moelans N, Spaepen F, Wollants P (2010) Grain growth in thin films with a fibre texture studied by phase-field simulations and mean field modelling. Philos Mag 90:501523

Holm EA, Hassold GN, Miodownik MA (2001) On misorientation distribution evolution during anisotropic grain growth. Acta Mater 49:2981–2991

Gruber J, Miller HM, Hoffmann TD, Rohrer GS, Rollett AD (2009) Misorientation texture development during grain growth. Part I: simulation and experiment. Acta Mater 57:6102–6112

Cahn JW (1991) Stability, microstructural evolution, grain growth, and coarsening in a two-dimensional two-phase microstructure. Acta Metall 39:2189–2199

Krill C, Chen LQ (2002) Computer simulation of 3-D grain growth using a phase-field model. Acta Mater 50:3057–3073

Acknowledgements

This project has received funding from the ‘Strategic Initiative Materials’ in Flanders (SIM) and the Institute for Innovation through Science and Technology in Flanders (IWT) under the Solution based Processing of Photovoltaic Modules (SoPPoM) program, CREA/12/012 Phase-field modeling of morphology evolution during phase transitions in inorganic nanomaterials, and the European Research Council (ERC) under the European Union’s Horizon 2020 research and innovation program (Grant Agreement No. 714754 – INTERDIFFUSION –ERC-2016-STG). The computational resources and services used in this work were provided by the VSC (Flemish Supercomputer Center), funded by the Research Foundation—Flanders (FWO) and the Flemish Government department EWI.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest that may have biased this work.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ravash, H., Vleugels, J. & Moelans, N. Three-dimensional phase-field simulation of microstructural evolution in three-phase materials with different interfacial energies and different diffusivities. J Mater Sci 52, 13852–13867 (2017). https://doi.org/10.1007/s10853-017-1465-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1465-z