Abstract

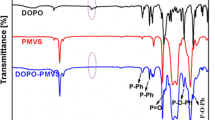

The introduction of fillers/additives into polymer matrices is a practical and effective method for preparation of damping materials. In the current work, a designed 9,10-dihydro-9-oxa-10-phosphaphenanthrene 10-oxide-based oligosiloxane (DOPO-PMVS) was used as an additive to improve the damping properties of methyl phenyl vinyl silicone rubber (PVMQ). The preparation of high damping PVMQ elastomers with broad temperature range has been discussed, and the effect of silica, DOPO-PMVS, vinyl content of PVMQ, and frequency has been investigated. The damping mechanism involves hydrogen bonding interactions between DOPO-PMVS and silica instead of the PVMQ matrix. Also, the static mechanical and aging properties of PVMQ demonstrated a reasonably good performance. Interestingly, the dynamic mechanical analysis showed that via incorporation of 50 wt% silica and 10 wt% DOPO-PMVS, the loss tangents (tan δ) of PVMQ elastomers significantly improved in the temperature range of approximately 0–200 °C and the maximum tan δ reached 0.55. Furthermore, the effective damping temperature ranges (tan δ ≥ 0.3) were more than 125, 100, and 40 °C for PVMQ-1, PVMQ-2, and PVMQ-3 (5 Hz excepted) matrix, respectively. Also, even after aging at 160 °C for 24 h, the effective damping temperature ranges remained at more than 100, and 70 °C for PVMQ-1, and PVMQ-2 matrix, respectively. Hence, the elastomers provided decent damping properties and the study provides a novel and promising method for the preparation of high damping silicon rubbers with broad temperature range.

Similar content being viewed by others

References

Zhou Y, Zhang CQ, Lu XL (2017) Seismic performance of a damping outrigger system for tall buildings. Struct Control Health. doi:10.1002/stc.1864

Kalinichenko VA, Soe AN, Chashechkin YD (2015) Vortex-induced damping of fluid oscillations in a rectangular vessel. Fluid Dyn 50:635–645

Wang XP, Zhang Y, Xia Y, Jiang WB, Liu H, Liu W, Gao YX, Zhang T, Fang QF (2017) Enhanced micro-vibration sensitive high-damping capacity and mechanical strength achieved in al matrix composites reinforced with garnet-like lithium electrolyte. Front Mater Sci 11:75–81

Hwang JS, Sheng LH (1993) Effective stiffness and equivalent damping of base-isolated bridges. J Struct Eng Asce 119:3094–3101

Quan S, Juan T, Qiang M (2009) Damage effect analysis and experiment for electronic equipment in impact vibration environment. J Syst Eng Electron 20:1384–1388

Smith MG, Croy I, Ogren M, Waye KP (2013) On the influence of freight trains on humans: a laboratory investigation of the impact of nocturnal low frequency vibration and noise on sleep and heart rate. PLoS ONE. doi:10.1371/journal.pone.0055829

Iamamura B, Rossi M, Hecquet M, Lanfranchi V, Recorbet S, Tridon F (2016) Vibration and acoustic noise of industrial inductors associated to converters in the railway domain design and material impacts. Compel 35:1900–1909

Gruebner O, Rapp MA, Adli M, Kluge U, Galea S, Heinz A (2017) Cities and mental health. Dtsch Arztebl Int 114:121–127

Dziopa Z, Koruba Z (2015) The impact of launcher turret vibrations control on the rocket launch. Bull Pol Acad Sci Tech 63:717–728

Zhou XQ, Yu DY, Shao XY, Zhang SQ, Wang S (2016) Research and applications of viscoelastic vibration damping materials: a review. Compos Struct 136:460–480

Wang W, Zhao D, Yang J, Nishi T, Ito K, Zhao X, Zhang L (2016) Novel slide-ring material/natural rubber composites with high damping property. Sci Rep. doi:10.1038/srep22810

Wang D, Zhang H, Guo J, Cheng B, Cao Y, Lu S, Zhao N, Xu J (2016) Biomimetic gradient polymers with enhanced damping capacities. Macromol Rapid Commun 37:655–661

Treviso A, Van Genechten B, Mundo D, Tournour M (2015) Damping in composite materials: properties and models. Compos Part B Eng 78:144–152

Lu X, Li XJ, Tian M (2014) Preparation of high damping elastomer with broad temperature and frequency ranges based on ternary rubber blends. Polym Adv Technol 25:21–28

Chung DDL (2001) Materials for vibration damping. J Mater Sci 36:5733–5737. doi:10.1023/A:1012999616049

Ward IM, Sweeney J (2004) An introduction to the mechanical properties of solid polymers, 2nd edn. Wiley, Chichester

Su C, Zhao CB, Xu LH, Zhang C (2015) Effects of chemical structure of phenolic resin on damping properties of acrylate rubber-based blends. J Macromol Sci B 54:177–189

Zhang FS, He GS, Xu KM, Wu H, Guo SY, Zhang CL (2014) Damping mechanism and different modes of molecular motion through the glass transition of chlorinated butyl rubber and petroleum resin blends. J Appl Polym Sci. doi:10.1002/app.40464

Shi XY, Bi WN, Zhao SG (2012) DMA analysis of the damping of ethylene–vinyl acetate/acrylonitrile butadiene rubber blends. J Appl Polym Sci 124:2234–2239

Mok MM, Kim J, Torkelson JM (2008) Gradient copolymers with broad glass transition temperature regions: design of purely interphase compositions for damping applications. J Polym Sci Polym Phys 46:48–58

Li FK, Larock RC (2002) New soybean oil–styrene–divinylbenzene thermosetting copolymers—iv. Good damping properties. Polym Adv Technol 13:436–449

Leng XF, Wei ZY, Ren YY, Bian YF, Wang QY, Li Y (2016) Copolymerization of l-lactide/trimethylene carbonate by organocatalysis: controlled synthesis of comb-like graft copolymers with side chains with different topologies. Rsc Adv 6:40371–40382

Culin J (2016) Interpenetrating polymer network composites containing polyurethanes designed for vibration damping. Polimery W 61:159–165

Wang C, Jia JR (2014) Damping and mechanical properties of polyol cross-linked polyurethane/epoxy interpenetrating polymer networks. High Perform Polym 26:240–244

Wang YB, Huang ZX, Zhang LM (2006) Damping properties of silicone rubber/polyacrylate sequential interpenetrating networks. Trans Nonferrous Metals Soc 16:S517–S520

Varischetti J, Jang JS, Gibson RF, Suhr J (2013) Effect of filler waviness and orientation on the damping behavior of CNF-reinforced epoxy composites. J Mater Sci 48:832–840. doi:10.1007/s10853-012-6803-6

Sirisinha C, Prayoonchatphan N (2001) Study of carbon black distribution in br/nbr blends based on damping properties: influences of carbon black particle size, filler, and rubber polarity. J Appl Polym Sci 81:3198–3203

Kwak GH, Inoue K, Tominaga Y, Asai S, Sumita M (2001) Characterization of the vibrational damping loss factor and viscoelastic properties of ethylene–propylene rubbers reinforced with micro-scale fillers. J Appl Polym Sci 82:3058–3066

Wu C, Yamagishi T-A, Nakamoto Y, Ishida S, Nitta K-H, Kubota S (2000) Organic hybrid of chlorinated polyethylene and hindered phenol. I. Dynamic mechanical properties. J Polym Sci Polym Phys 38:2285–2295

Wu C, Yamagishi T-A, Nakamoto Y, Ishida S-I, Kubota S, Nitta K-H (2000) Organic hybrid of chlorinated polyethylene and hindered phenol. II. Influence of the chemical structure of small molecules on viscoelastic properties. J Polym Sci Polym Phys 38:1496–1503

Wu C, Yamagishi T-A, Nakamoto Y, Ishida S-I, Nitta K-H (2000) Organic hybrid of chlorinated polyethylene and hindered phenol. III. Influence of the molecular weight and chlorine content of the polymer on the viscoelastic properties. J Polym Sci Polym Phys 38:2943–2953

Wu C (2001) Organic hybrid of chlorinated polyethylene and hindered phenol. IV. Modification on dynamic mechanical properties by chlorinated paraffin. J Polym Sci Polym Phys 39:23–31

Wu C, Akiyama S (2003) Dynamic properties of carbon black filled chlorinated polyethylene/hindered phenol blends. Polym Int 52:1249–1255

Zhao X-Y, Xiang P, Tian M, Fong H, Jin R, Zhang L-Q (2007) Nitrile butadiene rubber/hindered phenol nanocomposites with improved strength and high damping performance. Polymer 48:6056–6063

Cao Y, Shen F, Mou H, Cao D, Xu H, Wu C (2010) Hydrogenated nitrile butadiene rubber and hindered phenol composite. I. Miscibility and dynamic mechanical property. Polym Eng Sci 50:2375–2381

Zhao XY, Cao YJ, Zou H, Li J, Zhang LQ (2012) Structure and dynamic properties of nitrile–butadiene rubber/hindered phenol composites. J Appl Polym Sci 123:3696–3702

Song M, Zhao X, Li Y, Hu S, Zhang L, Wu S (2014) Molecular dynamics simulations and microscopic analysis of the damping performance of hindered phenol AO-60/nitrile–butadiene rubber composites. Rsc Adv 4:6719–6729

Yin XT, Liu CY, Lin Y, Guan AG, Wu GZ (2015) Influence of hydrogen bonding interaction on the damping properties of poly(n-butyl methacrylate)/small molecule hybrids. J Appl Polym Sci. doi:10.1002/app.41954

Xu K, Zhang F, Zhang X, Guo J, Wu H, Guo S (2015) Molecular insights into the damping mechanism of poly(vinyl acetate)/hindered phenol hybrids by a combination of experiment and molecular dynamics simulation. RSC Adv 5:4200–4209

Liu B, Gao X, Zhao Y, Dai L, Xie Z, Zhang Z (2017) 9,10-dihydro-9-oxa-10-phosphaphenanthrene 10-oxide-based oligosiloxane as a promising damping additive for methyl vinyl silicone rubber (VMQ). J Mater Sci 52:8603–8617. doi:10.1007/s10853-017-1085-7

Liu LH, Yang SY, Zhang ZJ, Wang Q, Xie ZM (2003) Synthesis and characterization of poly(diethylsiloxane) and its copolymers with different diorganosiloxane units. J Polym Sci Polym Chem 41:2722–2730

Yue Y, Zhang H, Zhang Z, Chen Y (2013) Polymer–filler interaction of fumed silica filled polydimethylsiloxane investigated by bound rubber. Compos Sci Technol 86:1–8

Boonstra BB, Cochrane H, Dannenberg EM (1976) Reinforcement of silicone-rubber by particulate silica. Kaut Gummi Kunstst 29:29–39

Polmanteer KE (1988) Silicone-rubber, its development and technological-progress. Rubber Chem Technol 61:470–502

Pothan LA, Oommen Z, Thomas S (2003) Dynamic mechanical analysis of banana fiber reinforced polyester composites. Compos Sci Technol 63:283–293

Sirisinha C, Thunyarittikorn J, Yartpakdee S (1998) Study of carbon blade distribution in butadiene rubber-nitrile/butadiene rubber blends based on damping properties—effect of some grades of carbon black. Plast Rubber Compos Process 27:373–375

Maiti S, De SK, Bhowmick AK (1992) Quantitative estimation of filler distribution in immiscible rubber blends by mechanical damping studies. Rubber Chem Technol 65:293–302

Heng Z, Zeng Z, Chen Y, Zou H, Liang M (2015) Silicone modified epoxy resins with good toughness, damping properties and high thermal residual weight. J Polym Res. doi:10.1007/s10965-015-0852-x

Chen SB, Wang QH, Wang TM (2012) Damping, thermal, and mechanical properties of carbon nanotubes modified castor oil-based polyurethane/epoxy interpenetrating polymer network composites. Mater Des 38:47–52

Qian LJ, Zhi JG, Tong B, Shi JB, Yang F, Dong YP (2009) Synthesis and characterization of main-chain liquid crystalline copolyesters containing phosphaphenanthrene side-groups. Polymer 50:4813–4820

Acknowledgements

This work was financially supported by the National Natural Science Foundation of China (No. 51503211) without which the work presented in this article would not have been possible. Special acknowledgements are given to Prof. Zemin Xie for his enduring help during the study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, B., Gao, X., Zhao, Y. et al. Prospect of 9,10-dihydro-9-oxa-10-phosphaphenanthrene 10-oxide-based oligosiloxane in the preparation of high damping methyl phenyl vinyl silicone rubbers with broad temperature range. J Mater Sci 52, 13307–13317 (2017). https://doi.org/10.1007/s10853-017-1433-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1433-7