Abstract

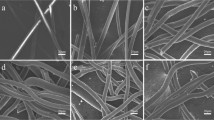

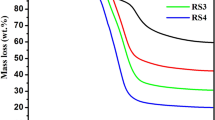

Activated carbon–carbon composites (ACCC) were prepared from low-cost, nonwoven like, continuous mesophase pitch-based carbon fibers and phenolic resin. The carbon fiber/phenolic resin composite was first fabricated by using a vacuum bagging resin infusion technique. The composite was carbonized in N2 at 1050 °C and then activated with CO2/H2O at 850 °C for about 5 h to obtain an ACCC. Optical microscope and SEM observations reveal that tiny cracks and channels are formed in the entire carbonized material due to the carbonization/shrinkage of the matrix, which are beneficial for the activation of carbon materials within the composite. After activation, the ACCC has a specific surface area of 800 m2/g and a resistivity of 470 μΩ m. Mini filters assembled with the ACCC is permeable and has high contact efficiency with the methylene blue in the breakthrough test. Gas adsorption experiments show that the ACCC material has a good adsorption performance for a variety of volatile organic compounds at room temperature. The prepared ACCC is expected not only to be used as an adsorbent but also as potential for use as an electrode material.

Similar content being viewed by others

References

Yue Z, Economy J (2016) Carbonization and activation for production of activated carbon fibers. In: Chen JY (ed) Activated carbon fiber and textiles. Woodhead Publishing, Amsterdam, Boston, Cambridge, Heidelberg, London, New York, Oxford, Paris, San Diego, San Francisco, Singapore, Sydney, Tokyo, pp 61–139

Ruiz V, Blanco C, Santamaría R, Ramos-Fernández JM, Martínez-Escandell M, Sepúlveda-Escribano A, Rodríguez-Reinoso F (2009) An activated carbon monolith as an electrode material for supercapacitors. Carbon 47:195–200

Crittenden B, Patton A, Jouin C, Perera S, Tennison S, Echevarria JAB (2005) Carbon monoliths: a comparison with granular materials. Adsorption 11:537–541

Kercher AK, Nagle DC (2003) Monolithic activated carbon sheets from carbonized medium-density fiberboard. Carbon 41:3–13

Gutiérrez-Pardo A, Ramírez-Rico J, de Arellano-López AR, Martínez-Fernández J (2014) Characterization of porous graphitic monoliths from pyrolyzed wood. J Mater Sci 49:7688–7696. doi:10.1007/s10853-014-8477-8

Saeidi N, Lotfollahi MN (2015) A procedure to form powder activated carbon into activated carbon monolith. Int J Adv Manuf Technol 81:1281–1288

Kimber GM (1999) Preparation of monolithic carbon fiber composite material, US patent 5972253

Brassell GW (1988) Activated carbon-carbon composite of high surface area and high compressive strength, US patent 4772508

Wilson KA, Burchell TD, Judkins RR (1998) Carbon fiber composite molecular sieve electrically regenerable air filter media, US patent 5827355

Burchell TD, Weaver CE, Chilcoat BR, Derbyshire F, Jagtoyen M (2000) Activated carbon fiber composite material and method of making. US patent 6030698

Burchell TD, Weaver CE, Chilcoat BR, Derbyshire F, Jagtoyen M (2001) Activated carbon fiber composite material and method of making. US patent 6258300 B1

Park SJ, Kim KD (2001) Influence of activation temperature on adsorption characteristics of activated carbon fiber composite. Carbon 39:1741–1746

Lee JC, Lee BH, Kim BG, Park MJ, Lee DY, Kuk IH, Chung H, Kang HS, Lee HS, Ahn DH (1997) The effect of carbonization temperature of PAN fiber on the properties of activated carbon fiber composites. Carbon 35:1479–1484

An H, Feng B, Su S (2009) CO2 capture capacities of activated carbon fibre–phenolic resin composites. Carbon 47:2396–2405

Yue ZR, Liu C, Vakili A (2017) Solvated mesophase pitch-based carbon fibers: thermal-oxidative stabilization of the spun fiber. J Mater Sci 52:8176–8187. doi:10.1007/s10853-017-1024-7

Vakili AD, Yue ZR (2012) Low cost carbon fiber technology development for carbon fiber composite applications. US DOT FTA Report No. 0011. https://www.transit.dot.gov/sites/fta.dot.gov/files/FTA_Report_No._0011.pdf. Accessed 2 May 2017

Yue ZR, Vakili A, Duran MP (2017) Surface treatments of solvated mesophase pitch-based carbon fibers. J Mater Sci 52:10250–10260. doi:10.1007/s10853-017-1197-0

Hashisho Z, Rood MJ, Barot S, Bernhard J (2009) Role of functional groups on the microwave attenuation and electric resistivity of activated carbon fiber cloth. Carbon 47:1814–1823

Wang CY, Inagaki M (1999) Oxidation resistance of pitch-based carbon fibers during heat treatment in carbon dioxide. Carbon 37(1):158–161

Acknowledgements

Much thanks to The UTSI Advanced Research Labs and Technical Support: Jim Goodman, Joel Davenport, Kate Lansford, Douglas Warnberg, and Gary Payne for their timely technical and component machining support and fabrication including numerous helpful discussions. Free samples of phenolic resin were provided by Georgia-Pacific Inc. This study was partially funded by Federal Transit Administration, US Department of Transportation (Grant No. TN-26-7029-00).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Yue, Z., Vakili, A. Activated carbon–carbon composites made of pitch-based carbon fibers and phenolic resin for use of adsorbents. J Mater Sci 52, 12913–12921 (2017). https://doi.org/10.1007/s10853-017-1389-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1389-7