Abstract

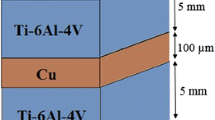

Ti–6Al–4V and AISI 304 stainless steel were joined by diffusion brazing with a Cu interlayer at 900 °C for different bonding times. The influence of the bonding time on the joint width, microstructure, microhardness and shear strength was studied. Interfacial characterizations and the identification of phases were done by scanning electron microscopy and electron backscatter diffraction (EBSD). The results revealed that by increasing the bonding time, the thickness of the joint was first increased and then decreased. Microstructure examinations also showed that the joints consisted of several intermetallics such as TiCu, Ti2Cu, TiCu4, TiCu2, FeTi and Fe2Ti. On the other hand, EBSD results demonstrated that the density of Cu–Ti intermetallics was reduced with the prolonged bonding time of 80 min, thereby indicating the occurrence of isothermal solidification. The microhardness profiles also showed a different behavior with varying the bonding time due to the change in the mechanism of the joint formation. The maximum shear strength obtained was 247 MPa, when the joint was bonded for 80 min; this was approximately equal to the stainless steel strength.

Similar content being viewed by others

References

Atasoy E, Kahraman N (2008) Diffusion bonding of commercially pure titanium to low carbon steel using a silver interlayer. Mater Charact 59:1481–1490

Leyens C, Peters M (2003) Titanium and titanium alloys. Wiley Online Library

Jiménez-Come M, Turias I, Trujillo F (2014) An automatic pitting corrosion detection approach for 316L stainless steel. Mater Des 56:642–648

Lo KH, Shek CH, Lai J (2009) Recent developments in stainless steels. Mater Sci Eng: R: Rep 65:39–104

Fuji A, Ameyama K, North T (1996) Improved mechanical properties in dissimilar Ti-AISI 304L joints. J Mater Sci 31:819–827. doi:10.1007/BF00367903

Serhan H, Slivka M, Albert T, Kwak SD (2004) Is galvanic corrosion between titanium alloy and stainless steel spinal implants a clinical concern? Spine J 4:379–387

Atabaki MM (2010) Microstructural evolution in the partial transient liquid phase diffusion bonding of Zircaloy-4 to stainless steel 321 using active titanium filler metal. J Nucl Mater 406:330–344

Williams JC, Belov A (1982) Titanium and titanium alloys: Scientific and technological aspects, vol 1. Plenum Press, New York

Kumar R, Balasubramanian M (2015) Experimental investigation of Ti–6Al–4V titanium alloy and 304L stainless steel friction welded with copper interlayer. Def Technol 11:65–75

Tomashchuk I, Sallamand P, Andrzejewski H, Grevey D (2011) The formation of intermetallics in dissimilar Ti6Al4V/copper/AISI 316 L electron beam and Nd: YAG laser joints. Intermetallics 19:1466–1473

Mousavi SA, Sartangi PF (2009) Experimental investigation of explosive welding of cp-titanium/AISI 304 stainless steel. Mater Des 30:459–468

Liu C, Ou C, Shiue R (2002) The microstructural observation and wettability study of brazing Ti–6Al–4V and 304 stainless steel using three braze alloys. J Mater Sci 37:2225–2235. doi:10.1023/A:1015356930476

Özdemir N, Bilgin B (2009) Interfacial properties of diffusion bonded Ti–6Al–4V to AISI 304 stainless steel by inserting a Cu interlayer. Int J Adv Manuf Technol 41:519–526

Ojo O, Richards N, Charturvedi M (2013) Effect of gap size and process parameters on diffusion brazing of Inconel 738. Sci Technol Weld Join 9(3):209–220

Cook GO III, Sorensen CD (2011) Overview of transient liquid phase and partial transient liquid phase bonding. J Mater Sci 46:5305–5323. doi:10.1007/s10853-011-5561-1

Deng Y, Sheng G, Wang F, Yuan X, An Q (2016) Microstructure evolution and mechanical properties of transient liquid phase bonded Ti–6Al–4V joint with copper interlayer. Mater Des 92:1–7

Norouzi E, Atapour M, Shamanian M, Allafchian A (2016) Effect of bonding temperature on the microstructure and mechanical properties of Ti–6Al–4V to AISI 304 transient liquid phase bonded joint. Mater Des 99:543–551

Ghosh M, Chatterjee S (2005) Effect of interface microstructure on the bond strength of the diffusion welded joints between titanium and stainless steel. Mater Charact 54:327–337

Zakipour S, Halvaee A, Amadeh AA, Samavatian M, Khodabandeh A (2015) An investigation on microstructure evolution and mechanical properties during transient liquid phase bonding of stainless steel 316L to Ti–6Al–4V. J Alloy Compd 626:269–276

Elrefaey A, Tillmann W (2009) Evaluation of transient liquid phase bonding between titanium and steel. Adv Eng Mater 11:556–560

Castoldi L, Visalli G, Morin S, Ferrari P, Alberici S, Ottaviani G, Corni DF, Tonini R, Nobili C, Bersani M (2004) Copper–titanium thin film interaction. Microelectron Eng 76:153–159

Vigraman T, Ravindran D, Narayanasamy R (2012) Effect of phase transformation and intermetallic compounds on the microstructure and tensile strength properties of diffusion-bonded joints between Ti–6Al–4V and AISI 304L. Mater Des 36:714–727

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Norouzi, E., Shamanian, M., Atapour, M. et al. Diffusion brazing of Ti–6Al–4V and AISI 304: an EBSD study and mechanical properties. J Mater Sci 52, 12467–12475 (2017). https://doi.org/10.1007/s10853-017-1376-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1376-z