Abstract

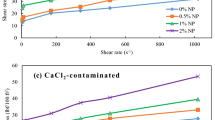

In recent years, shale gas has been an important fossil fuel. However, drilling in porous and water-sensitive shale using water-based drilling fluids (WBDs) can cause various problems, such as cuttings sedimentation, water penetration into the shale and drill pipe sticking. To solve these problems, this study demonstrated a two-dimensional nano-material (Laponite) as a multi-functional additive in WBDs for rheological control, nano-crack plugging and decreased drill pipe sticking. First, during rheological testing, the 2% Laponite suspension maintained good shear-thinning behavior in the elastic modulus (G′) and apparent viscosity after hot rolling at 150 °C compared with 6% sodium bentonite (Na-BT). Additionally, transmission electron microscopy analysis of the Laponite suspension demonstrated that the nano-sized Laponite layers maintained a better spatial network. Second, the Brunner–Emmet–Teller analysis of shale nano-pores indicated that shale immersed in the 2% Laponite suspension maintained a lower 10–100 nm nano-pore volume compared with 2% nano-SiO2 and 4% Na-BT. Furthermore, scanning electron microscopy of the shale showed that the Laponite layers plugged into the nano-pores, prevented free water from penetrating into the nano-cracks and decreased shale swelling in water. Third, the American Petroleum Institute filtration test showed that the Laponite suspension formed a far more smooth and compact filtrate cake than the Na-BT suspension. These unique abilities suggest that Laponite has the potential to be a multi-functional additive in WBDs for shale drilling to greatly improve rheological and nano-crack plugging properties and filtrate cake quality.

Similar content being viewed by others

References

Wang Q, Chen X, Jha AN, Rogers H (2014) Natural gas from shale formation—the evolution, evidences and challenges of shale gas revolution in United States. Renew Sustain Energy Rev 30:1–28

Curtis JB (2002) Fractured shale-gas systems. AAPG Bull 86:1921–1938

Gromet LP, Haskin LA, Korotev RL, Dymek RF (1984) The “North American shale composite”: its compilation, major and trace element characteristics. Geochim Cosmochim Acta 48:2469–2482

Jarvie DM, Hill RJ, Ruble TE, Pollastro RM (2007) Unconventional shale-gas systems: the Mississippian Barnett Shale of north-central Texas as one model for thermogenic shale-gas assessment. AAPG Bull 91:475–499

Zou Y, Yang C, Wu D, Yan C, Zeng M, Lan Y et al (2016) Probabilistic assessment of shale gas production and water demand at Xiuwu Basin in China. Appl Energy 180:185–195

Hammond GP, O’Grady Á (2017) Indicative energy technology assessment of UK shale gas extraction. Appl Energy 185:1907–1918

Kahn G, Mcdermott J (1986) The Mud System. IEEE Expert 1:23–32

Liang M, Wang Z, Gao L, Li C, Li H (2017) Evolution of pore structure in gas shale related to structural deformation. Fuel 197:310–319

Tang X, Jiang Z, Jiang S, Cheng L, Zhang Y (2017) Characteristics and origin of in situ gas desorption of the Cambrian Shuijingtuo Formation shale gas reservoir in the Sichuan Basin, China. Fuel 187:285–295

Loucks RG, Reed RM, Ruppel SC, Jarvie DM (2009) Morphology, Genesis, and distribution of nanometer-scale pores in siliceous mudstones of the Mississippian Barnett Shale. J Sediment Res 79:848–861

An Y, Jiang G, Qi Y, Ge Q, Zhang L, Ren Y (2015) Synthesis of nano-plugging agent based on AM/AMPS/NVP terpolymer. J Petrol Sci Eng 135:505–514

Xie G, Luo P, Deng M, Wang Z (2015) Nanoplugging performance of hyperbranched polyamine as nanoplugging agent in oil-based drilling fluid. J Nanomater 2015:1–8

An Y, Jiang G, Qi Y, Huang X, Shi H (2016) High-performance shale plugging agent based on chemically modified graphene. J Nat Gas Sci Eng 32:347–355

Akhtarmanesh S, Shahrabi MJA, Atashnezhad A (2013) Improvement of wellbore stability in shale using nanoparticles. J Petrol Sci Eng 112:290–295

Wu Y, Wang Z, Yan Z, Zhang T, Bai Y, Wang P et al (2017) Poly(2-acrylamide-2-methylpropanesulfonic acid)-modified SiO2 nanoparticles for water-based muds. Ind Eng Chem Res 56:168–174

Khalil M, Jan BM, Tong CW, Berawi MA (2017) Advanced nanomaterials in oil and gas industry: design, application and challenges. Appl Energy 191:287–310

Duran JD, Ramos-Tejada MM, Arroyo FJ, Gonzalez-Caballero F (2000) Rheological and electrokinetic properties of sodium montmorillonite suspensions. J Colloid Interface Sci 229:107–117

Liu F, Jiang G, Peng S, He Y, Wang J (2016) Amphoteric polymer as an anti-calcium contamination fluid-loss additive in water-based drilling fluids. Energy Fuels 30:7221–7228

Sadeghalvaad M, Sabbaghi S (2015) The effect of the TiO2/polyacrylamide nanocomposite on water-based drilling fluid properties. Powder Technol 272:113–119

William JKM, Ponmani S, Samuel R, Nagarajan R, Sangwai JS (2014) Effect of CuO and ZnO nanofluids in xanthan gum on thermal, electrical and high pressure rheology of water-based drilling fluids. J Petrol Sci Eng 117:15–27

Li MC, Wu Q, Song K, Qing Y, Wu Y (2015) Cellulose nanoparticles as modifiers for rheology and fluid loss in bentonite water-based fluids. ACS Appl Mater Interfaces 7:5006–5016

Ruzicka B, Zaccarelli E (2011) A fresh look at the Laponite phase diagram. Soft Matter 7:1268

Su D, Jiang L, Chen X, Dong J, Shao Z (2016) Enhancing the gelation and bioactivity of injectable silk fibroin hydrogel with laponite nanoplatelets. ACS Appl Mater Interfaces 8:9619–9628

Li C, Mu C, Lin W, Ngai T (2015) Gelatin effects on the physicochemical and hemocompatible properties of gelatin/PAAm/laponite nanocomposite hydrogels. ACS Appl Mater Interfaces 7:18732–18741

Wang Q, Mynar JL, Yoshida M, Lee E, Lee M, Okuro K et al (2010) High-water-content mouldable hydrogels by mixing clay and a dendritic molecular binder. Nature 463:339–343

Shahin A, Joshi YM, Ramakrishna SA (2011) Interface-induced anisotropy and the nematic glass/gel state in jammed aqueous Laponite suspensions. Langmuir ACS J Surf Colloids 27:14045–14052

Lian C, Lin Z, Wang T, Sun W, Liu X, Tong Z (2012) Self-reinforcement of PNIPAm–Laponite nanocomposite gels investigated by atom force microscopy nanoindentation. Macromolecules 45:7220–7227

Chen P, Xu S, Wu R, Wang J, Gu R, Du J (2013) A transparent Laponite polymer nanocomposite hydrogel synthesis via in situ copolymerization of two ionic monomers. Appl Clay Sci 72:196–200

Wang G, Maciel D, Wu Y, Rodrigues J, Shi X, Yuan Y et al (2014) Amphiphilic polymer-mediated formation of laponite-based nanohybrids with robust stability and pH sensitivity for anticancer drug delivery. ACS Appl Mater Interfaces 6:16687–16695

Rodell CB, Dusaj NN, Highley CB, Burdick JA (2016) Injectable and cytocompatible tough double-network hydrogels through tandem supramolecular and covalent crosslinking. Adv Mater 28:8419–8424

Pereira AS, Pinho FT (2002) Turbulent pipe flow of thixotropic fluids. Int J Heat Fluid Flow 23:36–51

Ida S, Manfred CI, Pål S, Arild S (2012) Experimental study of rheological properties of model drilling fluids. Annu Trans Nordi Rheol Soc 20:7

Huang Y, Wang L (2016) Experimental studies on nanomaterials for soil improvement: a review. Environ Earth Sci 75:1–10

Li MC, Wu Q, Song K, Lee S, Jin C, Ren S et al (2015) Soy protein isolate as fluid loss additive in bentonite–water-based drilling fluids. ACS Appl Mater Interfaces 7:24799–24809

Lopez Valdivieso A, Reyes Bahena JL, Song S, Herrera Urbina R (2006) Temperature effect on the zeta potential and fluoride adsorption at the alpha-Al2O3/aqueous solution interface. J Colloid Interface Sci 298:1–5

Angelini R, Zaccarelli E, de Melo Marques FA, Sztucki M, Fluerasu A, Ruocco G et al (2014) Glass-glass transition during aging of a colloidal clay. Nat Commun 5:4049

Hecht M, Harting J, Ihle T, Herrmann HJ (2005) Simulation of claylike colloids. Phys Rev E Stat Nonlin Soft Matter Phys 72:011408

Dijkstra M, Hansen JP, Madden PA (1995) Gelation of a clay colloid suspension. Phys Rev Lett 75:2236–2239

Ruzicka B, Zulian L, Ruocco G (2004) Routes to gelation in a clay suspension. Phys Rev Lett 93:258301

Segad M, Jönsson B, Cabane B (2012) Tactoid formation in montmorillonite. J Phys Chem C 116:25425–25433

Ali S, Bandyopadhyay R (2013) Use of ultrasound attenuation spectroscopy to determine the size distribution of clay tactoids in aqueous suspensions. Langmuir ACS J Surf Colloids 29:12663–12669

Stradner A, Sedgwick H, Cardinaux F, Poon WC, Egelhaaf SU, Schurtenberger P (2004) Equilibrium cluster formation in concentrated protein solutions and colloids. Nature 432:492–495

Ruzicka B, Zaccarelli E, Zulian L, Angelini R, Sztucki M, Moussaïd A et al (2011) Observation of empty liquids and equilibrium gels in a colloidal clay. Nat Mater 10:56–60

Klix CL, Royall CP, Tanaka H (2010) Structural and dynamical features of multiple metastable glassy states in a colloidal system with competing interactions. Phys Rev Lett 104:165702

Campbell AI, Anderson VJ, van Duijneveldt JS, Bartlett P (2004) Dynamical arrest in attractive colloids: the effect of long-range repulsion. Phys Rev Lett 94:208301

Shalkevich A, Stradner A, Bhat SK, Muller F, Schurtenberger P (2007) Cluster, glass, and gel formation and viscoelastic phase separation in aqueous clay suspensions. Langmuir ACS J Surf Colloids 23:3570–3580

Kroon M, Vos WL, Wegdam GH (1998) Structure and formation of a gel of colloidal disks. Int J Thermophys 19:887–894

Yu J, Andersson O, Johari GP (2014) Effects of nanometer-size Laponite disks on thermal conductivity and specific heat of water and ice, and the gelation time. Colloid Polym Sci 293:901–911

Sing KSW (2009) Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity (Recommendations 1984). Pure Appl Chem 57:603–619

Joyner LG, Barrett EP, Skold R (1951) The determination of pore volume and area distributions in porous substances. II. Comparison between nitrogen isotherm and mercury porosimeter methods. J Am Chem Soc 73:373–380

Acknowledgements

This research was supported by National Natural Science Foundation of China (Grant No. U1262201).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

All authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Liu, F., Jiang, GC., Wang, K. et al. Laponite nanoparticle as a multi-functional additive in water-based drilling fluids. J Mater Sci 52, 12266–12278 (2017). https://doi.org/10.1007/s10853-017-1375-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1375-0