Abstract

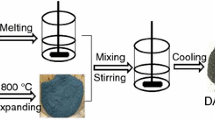

Carbon materials were added into stearic acid (SA) to improve the low thermal conductivity of SA, and their effect on thermal performance was investigated and compared. Stearic acid (SA)/expanded graphite (EG) and stearic acid (SA)/carbon nanotubes (CNTs) composite phase change materials (PCMs) were prepared via melt blending, vacuum adsorption and ultrasonication methods. Carbon additives were blended into SA with mass ratio from 1 to 9%. The leakage rate dropped dramatically with the increase in EG, and it was only physical adsorption in the preparation of both SA/EG and SA/CNTs composite PCMs. Thermophysical properties measured by TG-DSC showed that phase change temperatures of composite PCMs almost stayed the same and latent heat decreased slightly with increasing loadings of EG or CNTs. Thermal diffusivity and conductivity of pure SA were improved by adding EG and CNTs, while EG was far more effective than CNTs owing to the heat conduction network formed inside SA/EG composite PCMs, which was also the reason for the enhancement of thermal stability of SA/EG composite PCMs. Compared with pure SA, the thermal conductivity of composite PCMs was 6.2 times higher with 9 wt% EG and 1.4 times with 9 wt% CNTs, respectively. The heat storage and heat release efficiencies were also improved by carbon additives. This work demonstrates that EG is more potential to enhance the thermal performance of SA than CNTs, and SA/EG composite PCMs are quite promising for low-temperature solar energy storage.

Similar content being viewed by others

References

Pielichowska K, Pielichowski K (2014) Phase change materials for thermal energy storage. Prog Mater Sci 65:67–123

Sharma A, Tyagi VV, Chen CR et al (2009) Review on thermal energy storage with phase change materials and applications. Renew Syst Energy Rev 13:318–345

Liu C, Li F, Ma L et al (2010) Advanced materials for energy storage. Adv Mater 22:28–62

Shukla A, Buddhi D, Sawhney RL (2009) Solar water heaters with phase change material thermal energy storage medium: a review. Renew Syst Energy Rev 13:2119–2125

Kant K, Shukla A, Sharma A et al (2016) Thermal energy storage based solar drying systems: a review. Innov Food Sci Emerg 34:86–99

Iten M, Liu S, Shukla A (2016) A review on the air-PCM-TES application for free cooling and heating in the buildings. Renew Syst Energy Rev 61:175–186

He Y, Zhang X, Zhang Y et al (2016) Utilization of lauric acid-myristic acid/expanded graphite phase change materials to improve thermal properties of cement mortar. Energy Build 133:547–558

Pomianowski M, Heiselberg P, Zhang Y (2013) Review of thermal energy storage technologies based on PCM application in buildings. Energy Build 67:56–69

Sarier N, Onder E (2012) Organic phase change materials and their textile applications: an overview. Thermochim Acta 540:7–60

Mondal S (2008) Phase change materials for smart textiles—an overview. Appl Therm Eng 28:1536–1550

Shaikh S, Lafdi K (2010) C/C composite, carbon nanotube and paraffin wax hybrid systems for the thermal control of pulsed power in electronics. Carbon 48:813–824

Ling Z, Wang F, Fang X et al (2015) A hybrid thermal management system for lithium ion batteries combining phase change materials with forced-air cooling. Appl Energy 148:403–409

Javani N, Dincer I, Naterer GF (2014) New latent heat storage system with nanoparticles for thermal management of electric vehicles. J Power Sources 268:718–727

Lin C, Xu S, Chang G et al (2015) Experiment and simulation of a LiFePO4 battery pack with a passive thermal management system using composite phase change material and graphite sheets. J Power Sources 275:742–749

Yuan Y, Zhang N, Tao W et al (2014) Fatty acids as phase change materials: a review. Renew Syst Energy Rev 29:482–498

Shi J, Ger M, Liu Y et al (2013) Improving the thermal conductivity and shape-stabilization of phase change materials using nanographite additives. Carbon 51:365–372

Zhong Y, Zhou M, Huang F et al (2013) Effect of graphene aerogel on thermal behavior of phase change materials for thermal management. Sol Energy Mater Sol C 113:195–200

Mehrali M, Latibari ST, Mehrali M et al (2013) Shape-stabilized phase change materials with high thermal conductivity based on paraffin/graphene oxide composite. Energy Convers Manag 67:275–282

Cui Y, Liu C, Hu S et al (2011) The experimental exploration of carbon nanofiber and carbon nanotube additives on thermal behavior of phase change materials. Sol Energy Mater Sol C 95:1208–1212

Tang Y, Alva G, Huang X et al (2016) Thermal properties and morphologies of MA–SA eutectics/CNTs as composite PCMs in thermal energy storage. Energy Build 127:603–610

Zhang H, Gao X, Chen C et al (2016) A capric–palmitic–stearic acid ternary eutectic mixture/expanded graphite composite phase change material for thermal energy storage. Compos Part A Appl S 87:138–145

Xia L, Zhang P, Wang RZ (2010) Preparation and thermal characterization of expanded graphite/paraffin composite phase change material. Carbon 48:2538–2548

Fang G, Li H, Chen Z et al (2010) Preparation and characterization of stearic acid/expanded graphite composites as thermal energy storage materials. Energy 35:4622–4626

Yang X, Yuan Y, Zhang N et al (2014) Preparation and properties of myristic–palmitic–stearic acid/expanded graphite composites as phase change materials for energy storage. Sol Energy 99:259–266

Acknowledgements

This work was supported by the National Key Technology Research & Development Program of China (Grant No. 2012BAA05B05, Ministry of Science and Technology of the People’s Republic of China), Key Technology Research & Development Program of Hubei (Grant No. 2015BAA111, Science and Technology Department of Hubei Province) and the Fundamental Research Funds for the Central Universities (Grant No. WUT2017II23GX, Wuhan University of Technology).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

All authors declare no conflict of interest.

Rights and permissions

About this article

Cite this article

Cheng, X., Li, G., Yu, G. et al. Effect of expanded graphite and carbon nanotubes on the thermal performance of stearic acid phase change materials. J Mater Sci 52, 12370–12379 (2017). https://doi.org/10.1007/s10853-017-1350-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1350-9