Abstract

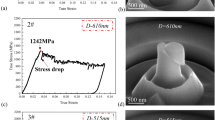

High-pressure torsion (HPT) deformation of multiphase metallic systems produces a high density of interfaces and leads to atomic mixing between the constituent phases. Here we present a study of the interphase boundary structure, grain size evolution and intermetallic phase formation during HPT deformation of a nano-crystalline Al/Ti composite. High-resolution transmission electron microscopy was used to study the structural features of the interphase boundaries. The Al/Ti interphase boundaries were found to significantly promote the generation of dislocations during deformation. After HPT deformation to a shear strain of 87, the average grain sizes of Al and Ti are 22 and 31 nm, respectively. The chemical mixing between the Al and Ti phases was enhanced by defect-mediated short circuit diffusion and dislocation shuffle-controlled plastic deformation at the interphase boundaries. The intermetallic phases formed during HPT deformation are associated with the strain energy stored by the high density of dislocations at the interphase boundaries.

Similar content being viewed by others

References

Straumal BB, Baretzky B, Mazilkin AA, Phillipp F, Kogtenkova OA, Volkov MN, Valiev RZ (2004) Formation of nanograined structure and decomposition of supersaturated solid solution during high pressure torsion of Al–Zn and Al–Mg alloys. Acta Mater 52(15):4469–4478

Sun YF, Fujii H, Nakamura T, Tsuji N, Todaka D, Umemoto M (2011) Critical strain for mechanical alloying of Cu–Ag, Cu–Ni and Cu–Zr by high-pressure torsion. Scripta Mater 65(6):489–492

Oh-ishi K, Edalati K, Kim HS, Hono K, Horita Z (2013) High-pressure torsion for enhanced atomic diffusion and promoting solid-state reactions in the aluminum–copper system. Acta Mater 61(9):3482–3489

Alhamidi A, Edalati K, Iwaoka H, Horita Z (2014) Effect of temperature on solid-state formation of bulk nanograined intermetallic Al3Ni during high-pressure torsion. Phil Mag 94(9):876–887

Alhamidi A, Edalati K, Horita Z (2013) Production of nanograined intermetallics using high-pressure torsion. Mater Res 16:672–678

Han J-K, Lee H-J, J-i Jang, Kawasaki M, Langdon TG (2017) Micro-mechanical and tribological properties of aluminum–magnesium nanocomposites processed by high-pressure torsion. Mater Sci Eng, A 684:318–327

Ahn B, Zhilyaev AP, Lee H-J, Kawasaki M, Langdon TG (2015) Rapid synthesis of an extra hard metal matrix nanocomposite at ambient temperature. Mater Sci Eng, A 635:109–117

Lee S, Edalati K, Iwaoka H, Horita Z, Ohtsuki T, Ohkochi T, Kotsugi M, Kojima T, Mizuguchi M, Takanashi K (2014) Formation of FeNi with L10-ordered structure using high-pressure torsion. Philos Mag Lett 94(10):639–646

Edalati K, Toh S, Watanabe M, Horita Z (2012) In situ production of bulk intermetallic-based nanocomposites and nanostructured intermetallics by high-pressure torsion. Scripta Mater 66(6):386–389

Bahmanpour H, Sun Y, Hu T, Zhang D, Wongsa-Ngam J, Langdon TG, Lavernia EJ (2014) Microstructural evolution of cryomilled Ti/Al mixture during high-pressure torsion. J Mater Res 29(04):578–585

Kawasaki M, Ahn B, Lee H, Zhilyaev AP, Langdon TG (2016) Using high-pressure torsion to process an aluminum–magnesium nanocomposite through diffusion bonding. J Mater Res 31(1):88–99

Kogtenkova OA, Mazilkin AA, Straumal BB, Abrosimova GE, Zięba P, Czeppe T, Baretzky B, Valiev RZ (2013) Phase transformations in Al–Mg–Zn alloys during high pressure torsion and subsequent heating. J Mater Sci 48(13):4758–4765. doi:10.1007/s10853-013-7266-0

Mahesh KK, Fernandes FMB, Gurau G (2012) Stability of thermal-induced phase transformations in the severely deformed equiatomic Ni–Ti alloys. J Mater Sci 47(16):6005–6014. doi:10.1007/s10853-012-6508-x

Haraguchi R, Yoshimatsu Y, Nagaoka T, Arita M, Edalati K, Horita Z (2017) Electrical resistivity mapping of titanium and zirconium discs processed by high-pressure torsion for homogeneity and phase transformation evaluation. J Mater Sci 52(11):6778–6788. doi:10.1007/s10853-017-0916-x

Adachi N, Todaka Y, Irie K, Umemoto M (2016) Phase transformation kinetics of ω-phase in pure Ti formed by high-pressure torsion. J Mater Sci 51(5):2608–2615. doi:10.1007/s10853-015-9574-z

Mazilkin AA, Abrosimova GE, Protasova SG, Straumal BB, Schütz G, Dobatkin SV, Bakai AS (2011) Transmission electron microscopy investigation of boundaries between amorphous “grains” in Ni50Nb20Y30 alloy. J Mater Sci 46(12):4336–4342. doi:10.1007/s10853-011-5304-3

Straumal BB, Protasova SG, Mazilkin AA, Rabkin E, Goll D, Schütz G, Baretzky B, Valiev RZ (2012) Deformation-driven formation of equilibrium phases in the Cu–Ni alloys. J Mater Sci 47(1):360–367. doi:10.1007/s10853-011-5805-0

Kawasaki M (2014) Different models of hardness evolution in ultrafine-grained materials processed by high-pressure torsion. J Mater Sci 49(1):18–34. doi:10.1007/s10853-013-7687-9

Révész Á, Kánya Z, Verebélyi T, Szabó PJ, Zhilyaev AP, Spassov T (2010) The effect of high-pressure torsion on the microstructure and hydrogen absorption kinetics of ball-milled Mg70Ni30. J Alloy Compd 504(1):83–88

Edalati K, Matsuda J, Iwaoka H, Toh S, Akiba E, Horita Z (2013) High-pressure torsion of TiFe intermetallics for activation of hydrogen storage at room temperature with heterogeneous nanostructure. Int J Hydrogen Energy 38(11):4622–4627

Edalati K, Matsuda J, Yanagida A, Akiba E, Horita Z (2014) Activation of TiFe for hydrogen storage by plastic deformation using groove rolling and high-pressure torsion: similarities and differences. Int J Hydrogen Energy 39(28):15589–15594

Edalati K, Emami H, Ikeda Y, Iwaoka H, Tanaka I, Akiba E, Horita Z (2016) New nanostructured phases with reversible hydrogen storage capability in immiscible magnesium–zirconium system produced by high-pressure torsion. Acta Mater 108:293–303

Emami H, Edalati K, Staykov A, Hongo T, Iwaoka H, Horita Z, Akiba E (2016) Solid-state reactions and hydrogen storage in magnesium mixed with various elements by high-pressure torsion: experiments and first-principles calculations. RSC Adv 6(14):11665–11674

Straumal B, Korneva A, Zięba P (2014) Phase transitions in metallic alloys driven by the high pressure torsion. Arch Civil Mech Eng 14(2):242–249

Straumal BB, Mazilkin AA, Baretzky B, Schütz G, Rabkin E, Valiev RZ (2012) Accelerated diffusion and phase transformations in Co–Cu alloys driven by the severe plastic deformation. Mater Trans 53(1):63–71

Straumal BB, Gornakova AS, Fabrichnaya OB, Kriegel MJ, Mazilkin AA, Baretzky B, Gusak AM, Dobatkin SV (2012) Effective temperature of high pressure torsion in Zr–Nb alloys. High Temp Mater Processes (London) 31(4–5):339–350

Vo NQ, Zhou J, Ashkenazy Y, Schwen D, Averback RS, Bellon P (2013) Atomic mixing in metals under shear deformation. JOM 65(3):382–389

Medyanik SN, Shao S (2009) Strengthening effects of coherent interfaces in nanoscale metallic bilayers. Comput Mater Sci 45(4):1129–1133

Sun Y, Kulkarni K, Sachdev AK, Lavernia EJ (2014) Synthesis of γ-TiAl by reactive spark plasma sintering of cryomilled Ti and Al powder blend, part I: influence of processing and microstructural evolution. Metall MaterTrans A 45(6):2750–2758

Figueiredo RB, Cetlin PR, Langdon TG (2011) Using finite element modeling to examine the flow processes in quasi-constrained high-pressure torsion. Mater Sci Eng, A 528(28):8198–8204

Figueiredo RB, Pereira PHR, Aguilar MTP, Cetlin PR, Langdon TG (2012) Using finite element modeling to examine the temperature distribution in quasi-constrained high-pressure torsion. Acta Mater 60(6–7):3190–3198

Mohamed FA, Dheda SS (2012) On the minimum grain size obtainable by high-pressure torsion. Mater Sci Eng, A 558:59–63

Edalati K, Akama D, Nishio A, Lee S, Yonenaga Y, Cubero-Sesin JM, Horita Z (2014) Influence of dislocation–solute atom interactions and stacking fault energy on grain size of single-phase alloys after severe plastic deformation using high-pressure torsion. Acta Mater 69:68–77

Wen H, Zhao Y, Li Y, Ertorer O, Nesterov KM, Islamgaliev RK, Valiev RZ, Lavernia EJ (2010) High-pressure torsion-induced grain growth and detwinning in cryomilled Cu powders. Phil Mag 90(34):4541–4550

Wang YB, Ho JC, Liao XZ, Li HQ, Ringer SP, Zhu YT (2009) Mechanism of grain growth during severe plastic deformation of a nanocrystalline Ni–Fe alloy. Appl Phys Lett 94(1):011908-1–011908-3

Liao XZ, Kilmametov AR, Valiev RZ, Gao H, Li X, Mukherjee AK, Bingert JF, Zhu YT (2006) High-pressure torsion-induced grain growth in electrodeposited nanocrystalline Ni. Appl Phys Lett 88(2):021909-1–021909-3

Semenova I, Timokhina I, Islamgaliev R, Lavernia E, Valiev R (2015) Nanocrystalline Ti produced by cryomilling and consolidation by severe plastic deformation. Metals 5(1):206–215

Sabbaghianrad S, Langdon TG (2014) A critical evaluation of the processing of an aluminum 7075 alloy using a combination of ECAP and HPT. Mater Sci Eng, A 596:52–58

Sabbaghianrad S, Langdon TG (2015) An evaluation of the saturation hardness in an ultrafine-grained aluminum 7075 alloy processed using different techniques. J Mater Sci 50(12):4357–4365. doi:10.1007/s10853-015-8989-x

Todaka Y, Umemoto M, Yamazaki A, Sasaki J, Tsuchiya K (2008) Influence of high-pressure torsion straining conditions on microstructure evolution in commercial purity aluminum. Mater Trans 49(1):7–14

Edalati K, Matsubara E, Horita Z (2009) Processing pure Ti by high-pressure torsion in wide ranges of pressures and strain. Metall MaterTrans A 40(9):2079–2086

Sauvage X, Jessner P, Vurpillot F, Pippan R (2008) Nanostructure and properties of a Cu–Cr composite processed by severe plastic deformation. Scripta Mater 58(12):1125–1128

Sauvage X, Wilde G, Divinski SV, Horita Z, Valiev RZ (2012) Grain boundaries in ultrafine grained materials processed by severe plastic deformation and related phenomena. Mater Sci Eng, A 540:1–12

Bachmaier A, Schmauch J, Aboulfadl H, Verch A, Motz C (2016) On the process of co-deformation and phase dissolution in a hard-soft immiscible CuCo alloy system during high-pressure torsion deformation. Acta Mater 115:333–346

Zhu YT, Langdon TG (2005) Influence of grain size on deformation mechanisms: an extension to nanocrystalline materials. Mater Sci Eng, A 409(1–2):234–242

Sinclair CW, Embury JD, Weatherly GC (1999) Basic aspects of the co-deformation of bcc/fcc materials. Mater Sci Eng, A 272(1):90–98

Hu SY, Choi J, Li YL, Chen LQ (2004) Dynamic drag of solute atmosphere on moving edge dislocations—Phase-field simulation. J Appl Phys 96(1):229–236

Guo Z, Miodownik AP, Saunders N, Schillé JP (2006) Influence of stacking-fault energy on high temperature creep of alpha titanium alloys. Scripta Mater 54(12):2175–2178

Karmaker G, Mukherjee P, Meikap AK, Chattopadhyay SK, Chatterjee SK (2001) An X-ray diffraction study of defect parameters in a Ti-base alloy. Bull Mater Sci 24(6):649–652

Zhang WJ, Appel F (2002) Weak-beam TEM study on planar fault energies of Al-lean TiAl-base alloys. Mater Sci Eng, A 334(1–2):59–64

Morishige T, Hirata T, Uesugi T, Takigawa Y, Tsujikawa M, Higashi K (2011) Effect of Mg content on the minimum grain size of Al–Mg alloys obtained by friction stir processing. Scripta Mater 64(4):355–358

Muzyk M, Pakiela Z, Kurzydlowski KJ (2011) Ab initio calculations of the generalized stacking fault energy in aluminium alloys. Scripta Mater 64(9):916–918

An XH, Lin QY, Wu SD, Zhang ZF, Figueiredo RB, Gao N, Langdon TG (2011) Significance of stacking fault energy on microstructural evolution in Cu and Cu–Al alloys processed by high-pressure torsion. Phil Mag 91(25):3307–3326

Zhao YH, Horita Z, Langdon TG, Zhu YT (2008) Evolution of defect structures during cold rolling of ultrafine-grained Cu and Cu–Zn alloys: influence of stacking fault energy. Mater Sci Eng, A 474(1–2):342–347

Raabe D, Ohsaki S, Hono K (2009) Mechanical alloying and amorphization in Cu–Nb–Ag in situ composite wires studied by transmission electron microscopy and atom probe tomography. Acta Mater 57(17):5254–5263

Drbohlav O, Yavari AR (1995) Mechanical alloying and thermal decomposition of ferromagnetic nanocrystalline f.c.c.-Cu50Fe50. Acta Metall Mater 43(5):1799–1809

Murata Y, Nakaya I, Morinaga M (2008) Assessment of strain energy by measuring dislocation density in copper and aluminium prepared by ECAP and ARB. Mater Trans 49(1):20–23

Gale WF, Totemeier TC (eds) (2004) Smithells metals reference book, 8th edn. Butterworth-Heinemann, Oxford

Mirjalili M, Soltanieh M, Matsuura K, Ohno M (2013) On the kinetics of TiAl3 intermetallic layer formation in the titanium and aluminum diffusion couple. Intermetallics 32:297–302

Sun Y, Kulkarni K, Sachdev AK, Lavernia EJ (2014) Synthesis of γ-TiAl by reactive spark plasma sintering of cryomilled Ti and Al powder blend: part II: effects of electric field and microstructure on sintering kinetics. Metall MaterTrans A 45(6):2759–2767

Foadian F, Soltanieh M, Adeli M, Etminanbakhsh M (2014) A study on the formation of intermetallics during the heat treatment of explosively welded Al–Ti multilayers. Metall MaterTrans A 45(4):1823–1832

Sun Y, Haley J, Kulkarni K, Aindow M, Lavernia EJ (2015) Influence of electric current on microstructure evolution in Ti/Al and Ti/TiAl3 during spark plasma sintering. J Alloy Compd 648:1097–1103

Kulkarni KN, Sun Y, Sachdev AK, Lavernia E (2013) Field-activated sintering of blended elemental γ-TiAl powder compacts: porosity analysis and growth kinetics of Al3Ti. Scripta Mater 68(11):841–844

Gachon JC, Rogachev AS, Grigoryan HE, Illarionova EV, Kuntz JJ, Kovalev DY, Nosyrev AN, Sachkova NV, Tsygankov PA (2005) On the mechanism of heterogeneous reaction and phase formation in Ti/Al multilayer nanofilms. Acta Mater 53(4):1225–1231

Wöhlert S, Bormann R (1999) Phase selection governed by different growth velocities in the early stages of the Ti/Al phase reaction. J Appl Phys 85(2):825–832

Acknowledgements

This work was supported by the National Science Foundation under Grant Nos. CMMI-1601087 (EJL) and DMR-1160966 (TGL).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Sun, Y., Aindow, M., Hebert, R.J. et al. High-pressure torsion-induced phase transformations and grain refinement in Al/Ti composites. J Mater Sci 52, 12170–12184 (2017). https://doi.org/10.1007/s10853-017-1331-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1331-z