Abstract

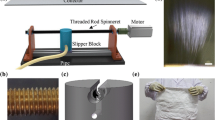

Slot electrospinning that uses narrow slot as a spinneret combines the advantages of both needle and needleless electrospinning with precisely controlled solution condition. Most of the existing slot electrospinning techniques, however, use a straight linear slot as spinneret. The effects of slot geometry on electrospinning process and fiber morphology have not been reported in the research literature. In this study, four convex slots with different line shapes, i.e., curved, straight, rectangle and triangle, have been used as spinnerets to examine the effects of slot line shape on electrospinning process, fiber morphology and productivity. The electric field intensity distribution of these slot spinnerets was analyzed by finite element method. Our experimental results have indicated that the slot line shape played an important role in affecting fiber diameter, productivity and uniformity of the fibrous membranes. Compared to the other slots studied, the curved slot can produce nanofibers with larger productivity and the resulting fibrous membranes were more uniform as well; the curved slot had higher electric field with more uniform distribution of electric field intensity along the slot length direction. These understandings may be helpful for designing new slot electrospinning systems.

Similar content being viewed by others

References

Darrell HR, Iksoo C (1996) Nanometre diameter fibres of polymer, produced by electrospinning. Nanotechnology 7:216

Choi SW, Jo SM, Lee WS, Kim YR (2003) An electrospun poly(vinylidene fluoride) nanofibrous membrane and its battery applications. Adv Mater 15:2027

Choi SW, Kim JR, Jo SM, Lee WS, Kim Y-R (2005) Electrochemical and spectroscopic properties of electrospun PAN-based fibrous polymer electrolytes. J Electrochem Soc 152:A989

Fang J, Niu H, Lin T, Wang X (2008) Applications of electrospun nanofibers. Chin Sci Bull 53:2265

Gibson P, Schreuder-Gibson H, Rivin D (2001) Transport properties of porous membranes based on electrospun nanofibers. Colloids Surf Physicochem Eng Aspects 187–188:469

Khil MS, Cha DI, Kim HY, Kim IS, Bhattarai N (2003) Electrospun nanofibrous polyurethane membrane as wound dressing. J Biomed Mater Res B Appl Biomater 67:675

Kim K, Luu YK, Chang C et al (2004) Incorporation and controlled release of a hydrophilic antibiotic using poly(lactide-co-glycolide)-based electrospun nanofibrous scaffolds. J Control Release 98:47

Baba R, Jayaram SH (2010) Industry applications society annual meeting (IAS), 2010 IEEE

Varesano A, Carletto RA, Mazzuchetti G (2009) Experimental investigations on the multi-jet electrospinning process. J Mater Process Technol 209:5178

Zhmayev E, Cho D, Joo YL (2010) Nanofibers from gas-assisted polymer melt electrospinning. Polymer 51:4140

Yarin AL, Zussman E (2004) Upward needleless electrospinning of multiple nanofibers. Polymer 45:2977

Jirsak O, Sanetrnik F, Lukas D, Kotek V, Martinova L, Chaloupek J (2005) WO 2005/024101 A1

Liu Y, He JH (2007) Bubble electrospinning for mass production of nanofibers. Int J Non Sci Numer Simul 8:393

Liu Y, He J-H, Yu J-Y (2008) Bubble-electrospinning: a novel method for making nanofibers. J Phys 96:012001

Niu H, Wang X, Lin T (2012) Needleless electrospinning: influences of fibre generator geometry. J Text Inst 103:787

Holopainen J, Penttinen T, Santala E, Ritala M (2015) Needleless electrospinning with twisted wire spinneret. Nanotechnology 26:025301

Shin HU, Li Y, Paynter A, Nartetamrongsutt K, Chase GG (2015) Microscopy analysis and production rate data for needleless vertical rods electrospinning parameters. Data Brief 5:41

Shin HU, Li Y, Paynter A, Nartetamrongsutt K, Chase GG (2015) Vertical rod method for electrospinning polymer fibers. Polymer 65:26

Molnar K, Nagy ZK (2016) Corona-electrospinning: needleless method for high-throughput continuous nanofiber production. Eur Polym J 74:279

Lawson C, Stanishevsky A, Sivan M, Pokorny P, Lukas D (2016) Rapid fabrication of poly(epsilon-caprolactone) nanofibers using needleless alternating current electrospinning. J Appl Polym Sci 133:43232

Bhattacharyya I, Molaro MC, Braatz RD, Rutledge GC (2016) Free surface electrospinning of aqueous polymer solutions from a wire electrode. Chem Eng J 289:203

Forward KM, Rutledge GC (2012) Free surface electrospinning from a wire electrode. Chem Eng J 183:492

Forward KM, Flores A, Rutledge GC (2013) Production of core/shell fibers by electrospinning from a free surface. Chem Eng Sci 104:250

Ucar N, Ucar M (2013) Design of a novel nozzle prototype for increased productivity and improved coating quality during electrospinning. Tekstil ve Konfeksiyon 23:199

Yan X, Marini J, Mulligan R et al (2015) Slit-surface electrospinning: a novel process developed for high-throughput fabrication of core-sheath fibers. PLoS ONE 10:e0125407

H Niu, T Lin (2012) Fiber Generators in Needleless Electrospinning. J. Nanomater.:

Niu H, Wang X, Lin T (2012) Upward needleless electrospinning of nanofibers. J Eng Fibers Fabr 7:17

Wang X, Wang X, Lin T (2012) Electric field analysis of spinneret design for needleless electrospinning of nanofibers. J Mater Res 27:3013

Wang X, Wang X, Lin T (2014) 3D electric field analysis of needleless electrospinning from a ring coil. J Ind Text 44:463

Wang X, Niu H, Wang X, Lin T (2012) Needleless electrospinning of uniform nanofibers using spiral coil spinnerets. J Nanomater 2012:785920

Author information

Authors and Affiliations

Corresponding author

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yan, G., Niu, H., Shao, H. et al. Curved convex slot: an effective needleless electrospinning spinneret. J Mater Sci 52, 11749–11758 (2017). https://doi.org/10.1007/s10853-017-1315-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-1315-z