Abstract

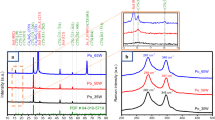

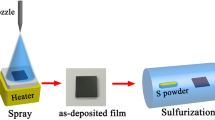

In this paper, Cu2SnS3 (CTS) thin film is fabricated through sulfurization of oxide precursor which is deposited by pulsed laser deposition with a mixed CuO/SnO2 target. XRD and Raman analyses indicate a pure monoclinic Cu2SnS3 phase has been obtained by sulfurization at temperature from 500 to 600 °C. A compact and smooth film with polycrystalline structure is observed through SEM result. In addition, the CTS films show excellent absorbance with the band gap around 0.91 eV estimated by UV–Vis, which is suitable for the absorption layer of solar cells. Final devices were fabricated with a SLG/Mo/CTS/CdS/i-ZnO/AZO/Al structure. Device performance is improved with the temperature increasing. The best efficiency of CTS-based solar cells is 0.69% with an open-circuit voltage of 144 mV and a short-circuit current density of 18.30 mA/cm−2.

Similar content being viewed by others

References

Abermann S (2013) Non-vacuum processed next generation thin film photovoltaics: towards marketable efficiency and production of CZTS based solar cells. Sol Energy 94:37–70. doi:10.1016/j.solener.2013.04.017

Berg DM, Djemour R, Gütay L, Zoppi G, Siebentritt S, Dale PJ (2012) Thin film solar cells based on the ternary compound Cu2SnS3. Thin Solid Films 520:6291–6294. doi:10.1016/j.tsf.2012.05.085

Fan D, Zhang J, Wang X, Xu M, Xu S (2015) Three-step process improves crystal quality of Cu2ZnSnS4 absorber layer and efficiency of solar cell. Cryst Res Technol 50:613–620. doi:10.1002/crat.201500025

Agawane GL, Kamble AS, Vanalakar SA et al (2015) Fabrication of 3.01% power conversion efficient high-quality CZTS thin film solar cells by a green and simple sol–gel technique. Mater Lett 158:58–61. doi:10.1016/j.matlet.2015.05.036

Zhao W, Wang G, Tian Q, Yang Y, Huang L, Pan D (2014) Fabrication of Cu2ZnSn(S, Se)4 solar cells via an ethanol-based sol–gel route using SnS2 as Sn source. ACS Appl Mater Interfaces 6:12650–12655. doi:10.1021/am5026006

McMeekin DP, Sadoughi G, Rehman W, Eperon GE, Saliba M, Hörantner MT, Haghighirad A, Sakai N, Korte L, Rech B, Johnston MB, Herz LM, Snaith HJ (2016) A mixed-cation lead mixed-halide perovskite absorber for tandem solar cells. Science 351:151–155

Kephart JM, McCamy JW, Ma Z, Ganjoo A, Alamgir FM, Sampath WS (2016) Band alignment of front contact layers for high-efficiency CdTe solar cells. Sol Energy Mater Sol Cells 157:266–275. doi:10.1016/j.solmat.2016.05.050

Babayigit A, Ethirajan A, Muller M, Conings B (2016) Toxicity of organometal halide perovskite solar cells. Nat Mater 15:247–251. doi:10.1038/nmat4572

Ali N, Hussain A, Ahmed R et al (2016) Advances in nanostructured thin film materials for solar cell applications. Renew Sustain Energy Rev 59:726–737. doi:10.1016/j.rser.2015.12.268

Chen Q, Dou X, Ni Y, Cheng S, Zhuang S (2012) Study and enhance the photovoltaic properties of narrow-bandgap Cu2SnS3 solar cell by p–n junction interface modification. J Colloid Interface Sci 376:327–330. doi:10.1016/j.jcis.2012.03.015

Zhang H, Xie M, Zhang S, Xiang Y (2014) Fabrication of highly crystallized Cu2SnS3 thin films through sulfurization of Sn-rich metallic precursors. J Alloys Compd 602:199–203. doi:10.1016/j.jallcom.2014.03.014

Zawadzki P, Baranowski LL, Peng H et al (2013) Evaluation of photovoltaic materials within the Cu–Sn–S family. Appl Phys Lett 103:253902(01)–253902(05). doi:10.1063/1.4851896

Baranowski LL, Zawadzki P, Christensen S et al (2014) Control of doping in Cu2SnS3 through defects and alloying. Chem Mater 26:4951–4959. doi:10.1021/cm501339v

Chino K, Koike J, Eguchi S et al (2012) Preparation of Cu2SnS3 thin films by sulfurization of Cu/Sn stacked precursors. Jpn J Appl Phys 51:10NC35(01)–10NC35(04). doi:10.1143/jjap.51.10nc35

Nakashima M, Yamaguchi T, Itani H, Sasano J, Izaki M (2015) Cu2SnS3 thin film solar cells prepared by thermal crystallization of evaporated Cu/Sn precursors in sulfur and tin atmosphere. Phys Status Solidi 12:761–764. doi:10.1002/pssc.201400269

Vanalakar SA, Agawane GL, Kamble AS, Hong CW, Patil PS, Kim JH (2015) Fabrication of Cu2SnS3 thin film solar cells using pulsed laser deposition technique. Sol Energy Mater Sol Cells 138:1–8. doi:10.1016/j.solmat.2015.02.031

Chen G, Jiang G, Liu W, Chen X, Zhu C (2012) Solvent-free synthesis of oxides for CuInSe2 thin films fabrication. Appl Surf Sci 258:3428–3432. doi:10.1016/j.apsusc.2011.11.089

Aihara N, Araki H, Takeuchi A, Jimbo K, Katagiri H (2013) Fabrication of Cu2SnS3 thin films by sulfurization of evaporated Cu–Sn precursors for solar cells. Phys Status Solidi 10:1086–1092. doi:10.1002/pssc.201200866

Nair MTS, Lopez-Mata C, GomezDaza O, Nair PK (2003) Copper tin sulfide semiconductor thin films produced by heating SnS–CuS layers deposited. Semicond Sci Technol 18:755–759

Li J, Xue C, Wang Y, Jiang G, Liu W, Zhu C (2016) Cu2SnS3 solar cells fabricated by chemical bath deposition—annealing of SnS/Cu stacked layers. Sol Energy Mater Sol Cells 144:281–288. doi:10.1016/j.solmat.2015.09.017

Su Z, Sun K, Han Z et al (2012) Fabrication of ternary Cu–Sn–S sulfides by a modified successive ionic layer adsorption and reaction (SILAR) method. J Mater Chem 22:16346–16352. doi:10.1039/c2jm31669b

Fernandes PA, Salomé PMP, Da Cunha AF (2010) A study of ternary Cu2SnS3 and Cu3SnS4 thin films prepared by sulfurizing stacked metal precursors. J Phys D Appl Phys 43:215403(01)–215403(11). doi:10.1088/0022-3727/43/21/215403

Dong Y, He J, Sun L, Chen Y, Yang P, Chu J (2015) Effect of sulfurization temperature on properties of Cu2SnS3 thin films and solar cells prepared by sulfurization of stacked metallic precursors. Mater Sci Semicond Process 38:171–176. doi:10.1016/j.mssp.2015.04.026

He J, Sun L, Zhang K et al (2013) Effect of post-sulfurization on the composition, structure and optical properties of Cu2ZnSnS4 thin films deposited by sputtering from a single quaternary target. Appl Surf Sci 264:133–138. doi:10.1016/j.apsusc.2012.09.140

Jayasree Y, Chalapathi U, Sundara Raja V (2015) Growth of Cu2SnS3 thin films by a two-stage process: structural, microstructural and optical properties. J Mater Sci Mater Electron 26:5946–5951. doi:10.1007/s10854-015-3166-1

Wang Y, Li J, Xue C et al (2016) Investigation of the sulfurization process of Cu2SnS3 thin films with stacked layers CBD-Cu/SnS by rapid thermal process. Mater Lett 178:104–106. doi:10.1016/j.matlet.2016.04.140

Ye M, Wen X, Zhang N, Guo W, Liu X, Lin C (2015) In situ growth of CuS and Cu1.8S nanosheet. J Mater Chem A 3:9595–9600. doi:10.1039/C5TA00390C

Liang X, Cai Q, Xiang W, Chen Z, Zhong J, Wang Y, Shao M, Li Z (2013) Preparation and characterization of flower-like Cu2SnS3 nanostructures by solvothermal route. J Mater Sci Technol 29(3):231–236. doi:10.1016/j.jmst.2013.01.018

Chen Z, Zeng Q, Liu F, Jin G, Du X, Du J, Zhanga H, Yang B (2015) Efficient inorganic solar cells from aqueous nanocrystals: the impact of composition on carrier dynamics. RSC Adv 5:74263–74269. doi:10.1039/C5RA15805B

Nakashima M, Fujimoto J, Yamaguchi T, Izaki M (2015) Cu2SnS3 thin-film solar cells fabricated by sulfurization from NaF/Cu/Sn stacked precursor. Appl Phys Express 8:042303(01)–042303(04). doi:10.7567/apex.8.042303

Avellaneda D, Nair MTS, Nair PK (2010) Cu2SnS3 and Cu4SnS4 thin films via chemical deposition for photovoltaic application. J Electrochem Soc 157:D346–D352. doi:10.1149/1.3384660

Sato S, Sumi H, Shi G, Sugiyama M (2015) Investigation of the sulfurization process of Cu2SnS3 thin films and estimation of band offsets of Cu2SnS3-related solar cell structure. Phys Status Solidi 12:757–760. doi:10.1002/pssc.201400294

Acknowledgements

This work was supported by National Basic Research Program of China (973 Program)-2012CB922001 and the Fundamental Research Funds for the Central Universities, No. WK2060140022.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Wang, Y., Li, J., Xue, C. et al. Fabrication of Cu2SnS3 thin-film solar cells with oxide precursor by pulsed laser deposition. J Mater Sci 52, 6225–6234 (2017). https://doi.org/10.1007/s10853-017-0856-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-0856-5