Abstract

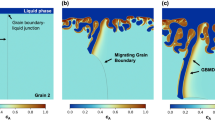

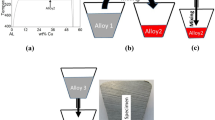

A numerical model is developed to study the splat morphology and solidification characteristics of a molten hypoeutectic alloy droplet impinging and solidifying on a substrate. The study finds application in optimization and improvement of metal additive manufacturing processes such as solder jetting, microcasting, sputtering and 3D printing. The major mathematical and numerical challenges include solution of multiphase flow governing equations, interface tracking and modeling the non-equilibrium (rapid) solidification on a macroscopic domain. The free surface is tracked using a volume of fluid method with a piecewise linear interface construction while the mushy phase is modelled as a pseudo porous medium. An enthalpy formulation of the energy equation is coupled with the solute transport equation and the system is solved simultaneously for the temperature and concentration profiles until the eutectic point is reached; beyond which a special treatment is employed till complete solidification. Segregation models (with back diffusion) and eutectic phase diagram are incorporated in the solution procedure. The splat morphology, concentration profiles and microstructural properties are closely examined with emphasis on the convective effects and eutectic formation.

Similar content being viewed by others

References

Cannon JR (1984) The one-dimensional heat equation. Addison Wesley, Boston, pp 281–326

Madejski J (1976) Solidification of droplets on a cold surface. Int J Heat Mass Transf 19:1009–1013

Aceves SM, Shapiro AB, Sahai V (1999) An accuracy evaluation for the Madejski splat-quench solidification model. ASME Int Mech Eng Congr Expos, Nashville, pp 273–280

Rangel RH, Bian X (1997) Metal-droplet deposition model including liquid deformaion and substrate remelting. Int J Heat Mass Transf 40:2549–2564

Pasandideh-Fard M, Bhola R, Chandra S, Mostaghimi J (1998) Deposition of tin droplets on a steel plate: simulations and experiments. Int J Heat Mass Transf 40:2929–2945

Liu H (2000) Science and engineering of droplets. Noyes Publications, New York, pp 193–232

Brent AD, Voller VR, Reid KJ (1988) Enthalpy-porosity technique for modeling convection-diffusion phase change: application to the melting of a pure metal. Numer Heat Transf 3:297–318

Attinger D, Haferi S, Zhao Z, Poulikakos D (2000) Transport phenomenon in the impact of a molten droplet on a surface: part II: heat transfer and solidfication. Ann Rev Heat Transf 11:145–206

Ni J, Beckermann C (1991) A volume-averaged two phase model for transport phenomenon during solidification. Metall Trans B 22(3):349–361

Voller VR, Brent AD, Prakash C (1989) The modeling of heat, mass and solute transport in solidification systems. Int J Heat Mass Transf 32(9):1719–1731

Voller VR (2006) Numerical methods for phase change problems, in handbook of numerical heat transfer, 2nd edn. Wiley, Hoboken, pp 593–622

Porter DA, Easterling KE, Sherif M (2009) Phase transformations in metals and alloys, 3rd edn. CRC Press, Boca Raton, pp 209–226

Ramanuj V (2016) Numerical modeling of an alloy droplet deposition with non-equilirium solidification. University of Texas at Arlington, Arlington, pp 28–70

Tong AY, Holt BR (1997) Numerical study on the solidification of liquid metal droplets impacting onto a substrate. Numer Heat Transf Part A Appl 8:797–817

Kothe DB, Mjolsness RC, Torrey MD (1991) RIPPLE: a computer program for incompressible flows with free surfaces. Los Alamos National Laboratory, Technical Report LA-12007-MS, Los Alamos, pp 3–35

Carman PC (1997) Fluid flow through granular beds. Chem Eng Res Des 75:32–48

Groulx D, Kheirabadi AC (2015) The effect of the mushy zone constant on simulated phase change heat transfer. In ICHMT International Symposium on Advances in Computational Heat Transfer, Piscataway

Brackbill JU, Kothe DB, Zemach C (1992) A continuum method for modeling surface tension. J Comput Phys 100(2):335–354

Kershaw DS (1978) The incomplete Cholesky—Conjugate gradient method for the iterative solution of systems of linear equations. J Comput Phys 26(1):43–65

Youngs DL (1982) Time-dependent multi-material flow with large fluid distortion. Numer Method Fluid Dyn 24:273–285

Rudman M (1997) Volume-tracking methods for interfacial flow calculations. Int J Numer Method Fluid 24(7):671–691

Voller VR, Cross M, Markatos NC (1987) An enthalpy method for convection/diffusion phase change. Int J Numer Method Eng 1:271–284

Patankar S (1992) Numerical heat transfer and fluid flow. CRC Press, Boston, pp 79–112

Voller VR (1997) A similarity solution for the solidification of a multicomponent alloy. Int J Heat Mass Transf 40(12):2869–2877

Kobayashi S (1988) Solute redistribution during solidification with diffusion in solid phase: a theoretical analysis. J Cryst Growth 88:87–96

Attinger D, Zhao Z, Poulikakos D (2000) An experimental study of molten microdroplet surface deposition and solidification: transport behavior and wetting angle dynamics. J Heat Transf 122:544–556

Tian D, Wang C, Tian Y (2008) Effect of solidification on solder bump formation in solder jet process: simulation and experiment. Trans Nonferrous Met Soc Chin 18:1201–1208

Ramanuj V, Tong AY (2016) Simultaneous spreading and solidification of an impacting molten droplet with substrate remelting. J Heat Transf 139(3):032301–032311

Pasandideh-Fard M (1998) Droplet impact and solidification in a thermal spray process. University of Toronto, Toronto, pp 110–135

Markworth AJ, Saunders JH (1992) An improved velocity field for the Madejski splat quench solidification Model. Int J Heat Mass Transf 19:1836–1837

Spinelli JE, Rocha OF, Garcia A (2006) The influence of melt convection on dendritic spacing of downward unsteady-state directionally solodified Sn–Pb alloys. Mater Res 9(1):51–57

Cadirli E, Gunduz M (2000) The dependence of lamellar spacing on growth rate and temperature gradient in the lead-tin eutectic alloy. J Mater Process Technol 97:74–81

Acknowledgement

The authors are thankful to The University of Texas at Arlington and The Texas Advanced Computing Center for providing the necessary computational resources.

Author information

Authors and Affiliations

Corresponding author

Appendix

Appendix

A uniform mesh was used for the study. Figure 18 the grid refinement results based on the convergence of free surface, spread factor and splat thickness. 0.02 mm × 0.02 mm was selected for the present analysis.

Rights and permissions

About this article

Cite this article

Ramanuj, V., Tong, A.Y. A numerical model for a hypoeutectic alloy droplet deposition with non-equilibrium solidification. J Mater Sci 52, 6034–6049 (2017). https://doi.org/10.1007/s10853-017-0842-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-0842-y