Abstract

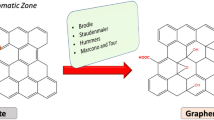

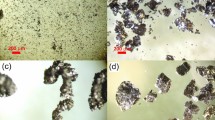

Discovery of nanographitic structure of remarkable properties such as fullerenes, carbon nanotubes and three-dimensional graphite nanoplatelets (3D-GNPs) opens the door for potential applications in science and technology. In the present work, graphite intercalation compound (GIC) technique with different acids ratio has been optimized for exfoliated graphite nanoplatelets (EGNPs), and the same optimum acids ratio has been used to successfully produce 3D-GNPs of 10 graphene layers and 145-nm lateral size. Raman spectroscopy, SEM, HRTEM and DLS techniques have been used to evaluate the thickness and number of layers of both EGNPs and 3D-GNPs. A new empirical formula based on Raman analysis has been introduced for the first time to evaluate the number of graphene layers, and it has been verified by using SEM, HRTEM and DLS results. This formula has been tested as well by using experimental data from the literature and found to be consistence and trusty used up to 30 graphene layers. Also, lateral size of graphitic structure has been measured and then evaluated by Lotya formula based on DLS data. The suggested empirical formula along with Lotya formula will open the door in the future work for extensive trials of GIC till reach to monographene layer.

Similar content being viewed by others

References

Geim AK, Novoselov KS (2007) The rise of graphene. Nat Mater 6:183–191

Lee C, Wei X, Kysar JW, Hone J (2008) Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 321:385–388

Stoller MD, Park S, Zhu Y, An J, Ruoff RS (2008) Graphene-based ultracapacitors. Nano Lett 8:3498–3502

Bolotin KI, Sikes KJ, Jiang Z, Klim M, Fudenberg G, Hone J, Kim P, Stormer HL (2008) Ultrahigh electron mobility in suspended graphene. Solid State Commun 146:351–355

Balandin AA, Ghosh S, Bao W, Calizo I, Teweldebrhan D, Miao F, Lau CN (2008) Superior thermal conductivity of single-layer graphene. Nano Lett 8:902–907

Khenfouch M, Buttner U, Baïtoul M, Maaza M (2014) Synthesis and characterization of mass produced high quality few layered graphene sheets via a chemical method. Graphene 3:7–13

Kedzierski J, Hsu P, Reina A, Kong J, Healey P, Wyatt P, Keast C (2009) Graphene-on-insulator transistors made using C on Ni chemical-vapor deposition. IEEE Electron Device lett 30:745–747

Wang X, Zhi L, Müllen K (2007) Transparent, conductive graphene electrodes for dye-sensitized solar cells. Nano Lett 8:323–327

Booth TJ et al (2008) Macroscopic graphene membranes and their extraordinary stiffness. Nano Lett 8:2442–2446

Mack JJ, Viculis LM, Ali A, Luoh R, Yang G, Hahn HT, Ko FK, Kaner RB (2005) Graphite nanoplatelet reinforcement of electrospun polyacrylonitrile nanofibers. Adv Mater 17:77–80

Ali AA (2008) Wear characteristics of exfoliated graphite nano sheets/copper metal matrix composite, the sixth international scientific conference, Scientific Bulletins of Rzeszów University of Technology Vol 253. Poland, pp. 19–26

Ali AA, Mansour A, Gewefel E, Agwa M (2013) Electrospun EGNPs/PS ultra-thin fibril composites: an idea for luminescence and thermal controllable strong fabrics. In: International conference in nanotechnology, biotechnology and spectroscopy (ICNBS), iSeS, Delta Pyramids hotel, Egypt, 29 Nov–1 Dec 2013

Novoselov KS, Geim AK, Morozov SV, Jiang D, Zhang Y, Dubonos SV, Grigorieva IV, Firsov AA (2004) Electric field effect in atomically thin carbon films. Science 306:666–669

Hernandez Y et al (2008) High-yield production of graphene by liquid-phase exfoliation of graphite. Nat Nano 3:563–568

Li X et al (2009) Large-area synthesis of high-quality and uniform graphene films on copper foils. Science 324:1312–1314

Ibrahim A, Akhtar S, Atieh M, Karnik R, Laoui T (2015) Effects of annealing on copper substrate surface morphology and graphene growth by chemical vapor deposition. Carbon 94:369–377

Choucair M, Thordarson P, Stride JA (2009) Gram-scale production of graphene based on solvothermal synthesis and sonication. Nat Nanotechnol 4:30–33

Singh V, Joung D, Zhai L, Das S, Khondaker SI, Seal S (2011) Graphene based materials: past, present and future. Prog Mater Sci 56:1178–1271

Torrisi F et al (2012) Inkjet-printed graphene electronics. ACS Nano 6:2992–3006

Hasan T, Torrisi F, Sun Z, Popa D, Nicolosi V, Privitera G, Bonaccorso F, Ferrari AC (2010) Solution-phase exfoliation of graphite for ultrafast photonics. Phys Status Solidi B 247:2953–2957

Ferrari AC et al (2006) Raman spectrum of graphene and graphene layers. Phys Rev Lett 97:187401–187404

Tuinstra F, Koenig JL (1970) Raman spectrum of graphite. J Chem Phys 53:1126–1130

Chen G, Wu D, Weng W, Wu C (2003) Exfoliation of graphite flake and its nanocomposites. Carbon 41:579–625

Chen G, Weng W, Wu D, Wu C, Lu J, Wang P, Chen X (2004) Preparation and characterization of graphite nanosheets from ultrasonic powdering technique. Carbon 42:753–759

Geng D, Wu B, Guo Y, Huang L, Xue Y, Chen J, Yu G, Jiang L, Hu W, Liu Y (2012) Uniform hexagonal graphene flakes and films grown on liquid copper surface. PNAS 109:7992–7996

Levendorf MP, Ruiz-Vargas CS, Garg S, Park J (2009) Transfer-free batch fabrication of single layer graphene transistors. Nano Lett 9:4479–4483

Cançado LG, Takai K, Enoki T, Endo M, Kim YA, Mizusaki H, Jorio A, Coelho LN, Magalhães-Paniago R, Pimenta MA (2006) General equation for the determination of the crystallite size La of nanographite by Raman spectroscopy. Appl Phys Lett 88:163106. doi:10.1063/1.2196057

Kang F, Zheng Y, Wang H, Nishi Y, Inagaki M (2002) Effect of preparation conditions on the characteristics of exfoliated graphite. Carbon 40:1575–1581

Stankovich S, Piner RD, Chen X, Wu N, Nguyen ST, Ruoff RS (2006) Stable aqueous dispersions of graphitic nanoplatelets via the reduction of exfoliated graphite oxide in the presence of poly(sodium 4-styrenesulfonate). J Mater Chem 16:155–158

Lotya M, Rakovich A, Donegan JF, Coleman JN (2013) Measuring the lateral size of liquid-exfoliated nanosheets with dynamic light scattering. Nanotechnol 24:265703

Ferrari AC (2007) Raman spectroscopy of graphene and graphite: disorder, electron-phonon coupling, doping and nonadiabatic effects. Solid State Commun 143:47–57

Liao K et al (2011) High-power splitting of expanded graphite to produce few-layer graphene sheets. Carbon 49:2862–2868

Das A et al (2008) Monitoring dopants by Raman scattering in an electrochemically top-gated graphene transistor. Nat Nanotechnol 3:210–215

Lotya M et al (2009) Liquid phase production of graphene by exfoliation of graphite in surfactant/water solutions. J Am Chem Soc 131:3611–3620

Xiang J, Drzal LT (2011) Thermal conductivity of exfoliated graphite nanoplatelet paper. Carbon 49:773–778

Lu S et al (2013) High pressure transformation of graphene nanoplates: a Raman study. Chem Phys Lett 585:101–106

Cooper AJ, Wilson NR, Kinloch IA, Dryfe RAW (2014) Single stage electrochemical exfoliation method for the production of few-layer graphene via intercalation of tetraalkylammonium cations. Carbon 66:340–350

Sole C, Drewett NE, Liu F, Abdelkader AM, Kinloch IA, Hardwick LJ (2015) The role of re-aggregation on the performance of electrochemically exfoliated many-layer graphene for Li-ion batteries. J Electroanal Chem 753:35–41

Usca GT, Hernandez-Ambato J, Pace C, Caputi LS, Tavolaro A (2016) Liquid-phase exfoliated graphene self-assembled films: low-frequency noise and thermal-electric characterization. Appl Surf Sci 380:268–273

Acknowledgements

Authors would like to thank NTC, Faculty of Engineering, Zagazig University, Egypt, for funding and allowing a free accessing of all experimental facilities. Also, authors would like to thank Atomic Energy Authority Nuclear Research Center and Petroleum Research Institute, Egypt, for samples morphological analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Mahdy, S.M., Gewfiel, E. & Ali, A.A. Production and characterization of three-dimensional graphite nanoplatelets. J Mater Sci 52, 5928–5937 (2017). https://doi.org/10.1007/s10853-017-0829-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-0829-8