Abstract

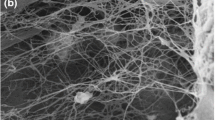

The ability of the bacteria Gluconacetobacter sucrofermentans to produce high-quality cellulose is well known. This bacterial cellulose has unique properties, as the result of an ultrathin crosslinked structure. It is almost chemically pure (until 98% cellulose), has a high crystallinity, mechanical strength, elasticity and durability. It is compatible with plant cellulose and could be grown on a vegetal fibrous network what makes bacterial cellulose an excellent candidate to reinforce damaged papers. The objective of this work is to promote the production of bacterial cellulose on the surface of a variety of papers by the direct application of a culture of G. sucrofermentans and to test if this procedure could be an economic and feasible possibility in reinforcing papers or cellulosic surfaces. After 7 days of cultivation, G. sucrofermentans deposits a thin layer (ca. 10 µm) of bacterial cellulose on the papers surfaces. Microscopic observations have shown a heterogeneous covering of the surfaces, while the modified papers maintain their thickness and their basic weight. The treatment has not increased the papers mechanical properties, but maintains them after artificial aging. The changes in optical properties of the reinforced papers, such as opacity and colorimetric coordinates, are minor even after further aging. Air permeance is the paper characteristic that experiences more variations because the layers of bacterial cellulose inhibit the airflow through the papers. The changes in the static and dynamic contact angles suggest that the bacterial cellulose structure is more compact and make the surface more hydrophobic than the original paper surface.

Similar content being viewed by others

References

Ahn K, Rosenau T, Potthast A (2013) The influence of alkaline reserve on the aging behavior of book papers. Cellulose 20:1989–2001

Bansa H, Ishii R (1997) The effect of different strengthening methods on different kinds of paper. Restaurator 18:51–72

Iguchi M, Yamanaka S, Budhiono A (2000) Bacterial cellulose: a masterpiece of nature’s arts. J Mater Sci 35:261–270. doi:10.1023/A:1004775229149

Chawla PR, Bajaj IB, Survase SA, Singhal RS (2009) Microbial cellulose: fermentative production and applications. Food Technol Biotechnol 47:107–124

Santos SM, Carbajo JM, Villar JC (2013) The effect of carbon and nitrogen sources on bacterial cellulose production and properties from Gluconacetobacter sucrofermentans CECT 7291 focused on its use in degraded paper restoration. BioResources 8(3):3630–3645

Santos SM, Carbajo JM, Quintana E, Ibarra D, Gómez N, Ladero M, Eugenio ME, Villar JC (2015) Characterization of purified bacterial cellulose focused on its use on paper restoration. Carbohydr Polym 116:173–181

Meftahi A, Khajavi R, Rashidi A, Sattari M, Yazdanshenas ME, Torabi M (2010) The effects of cotton gauze coating with microbial cellulose. Cellulose 17:199–204

Wu S, Li M, Fang B, Tong H (2012) Reinforcement of vulnerable historic silk fabrics with bacterial cellulose film and its light aging behavior. Carbohydr Polym 88:496–501

Saibuatong O, Phisalaphong M (2010) Novo aloe vera-bacterial cellulose composite film from biosynthesis. Carbohydr Polym 79(2):455–460

Serafica G, Mormino R, Bungay H (2002) Inclusion of solid particles in bacterial cellulose. Appl Microbiol Biotechnol 58:756–760

Hestrin S, Schramm M (1954) Synthesis of cellulose by Acetobacter xylinum. 2. Preparation of freeze-dried cells capable of polymerizing glucose to cellulose. Biochem J 58:345–352

Pommet M, Juntaro J, Heng JYY, Mantalaris A, Lee AF, Wilson K, Kalinka G, Shaffer MSP, Bismarck A (2008) Surface modification of natural fibers using bacteria: depositing bacterial cellulose onto natural fibers to create hierarchical fiber reinforced nanocomposites. Biomacromolecules 9:1643–1651

Santos SM, Carbajo JM, Gómez N, Quintana E, Ladero M, Sánchez A, Chinga-Carrasco G, Villar JC (2016) Use of bacterial cellulose in degraded paper restoration. Part II: application on real samples. J Mater Sci 51(3):1553–1561. doi:10.1007/s10853-015-9477-z

Santos SM, Carbajo JM, Gómez N, Quintana E, Ladero M, Sánchez A, Chinga-Carrasco G, Villar JC (2016) Use of bacterial cellulose in degraded paper restoration. Part I: application on model papers. J Mater Sci 51(3):1541–1552. doi:10.1007/s10853-015-9476-0

Yousefi H, Faezipour M, Hedjazi S, Mousavi MM, Azusa Y, Heidari AH (2013) Comparative study of paper and nanopaper properties prepared from bacterial cellulose nanofibres and fibres/ground cellulose nanofibres of canola straw. Ind Crop Prod 43:732–737

Fendler A, Villanueva MP, Giminez E, Lagarón JM (2007) Characterization of the barrier properties of composites of HDPE and purified cellulose fibers. Cellulose 14:427–438

Gao WH, Chen KF, Yang RD, Yang F, Han WJ (2011) Properties of bacterial cellulose and its influence on the physical properties of paper. BioResources 6:144–153

Kato KL, Cameron RE (1999) A review of the relationship between thermally accelerated ageing of paper and hornification. Cellulose 6:23–40

Fernandes-Diniz JMB, Gil MH, Castro JAAM (2004) Hornification-its origin and interpretation in wood pulps. Wood Sci Technol 37:489–494

Acknowledgements

The authors wish to thank the Spanish Ministry of Science and Innovation for funding this study via Project CTQ 2010-17702, and the Madrid Regional Government via Project RETOPROSOST P2013-MAE2907.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Santos, S.M., Carbajo, J.M., Gómez, N. et al. Paper reinforcing by in situ growth of bacterial cellulose. J Mater Sci 52, 5882–5893 (2017). https://doi.org/10.1007/s10853-017-0824-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-0824-0