Abstract

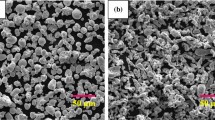

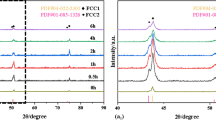

Equiatomic CuZr and CuZrAlTiNi bulk alloys were designed and fabricated by mechanical (MA) alloying and spark plasma sintering (SPS). The results show that during the MA process, the phases of as-milled samples transform from solid solutions to amorphous phases with increasing milling time. Moreover, the as-milled CuZrAlTiNi amorphous high entropy powders possess higher thermal stability and smaller particle sizes than the as-obtained CuZr powders. After SPS, the bulk CuZrAlTiNi samples are comprised of three solid solutions and a AlNi2Zr phase, and have good phase stability. The CuZrAlTiNi sample sintered at 950 °C shows the higher microhardness value of 1007 HV0.2 due to the fine precipitates, the existence of AlNi2Zr phase and solid solution strengthening. In addition, the chemical corrosion behavior of the as-sintered samples has been investigated in the seawater solution. The 950 °C-sintered CuZrAlTiNi sample exhibits excellent passivity and higher pitting resistance as compared to other sintered samples. All the CuZr and CuZrAlTiNi bulk samples show better corrosion resistance than 304 stainless steel revealed by the reduced corrosion rate.

Similar content being viewed by others

References

Guo S, Ng C, Wang ZJ, Liu CT (2014) Solid solutioning in equiatomic alloys: limit set by topological instability. J Alloys Compd 583:410–413

Yeh JW, Chen SK, Lin SJ, Gan JY, Chin TS, Shun TT et al (2004) Nanostructured high entropy alloys with multiple principal elements: novel alloy design concepts and outcomes. Adv Eng Mater 6:299–303

Chuang MH, Tsai MH, Wang WR, Lin SJ, Yeh JW (2011) Microstructure and wear behavior of Al x Co1.5CrFeNi1.5Ti y high-entropy alloys. Acta Mater 59:6308–6317

He JY, Liu WH, Wang H, Wu Y, Liu XJ, Nieh TG, Lu ZP (2014) Effects of Al addition on structural evolution and tensile properties of the FeCoNiCrMn high-entropy alloy system. Acta Mater 62:105–113

Zhang ZT, Axinte E, Ge WJ, Shang CY, Wang Y (2016) Microstructure, mechanical properties and corrosion resistance of CuZrY/Al, Ti, Hf series high-entropy alloys. Mater Des 108:106–113

Gao XQ, Zhao K, Ke HB, Ding DW, Wang WH, Bai HY (2011) High mixing entropy bulk metallic glasses. J Non-Cryst Solids 357:557–560

Fu ZQ, Chen WP, Xiao HQ, Zhou LW, Zhu DZ, Yang SF (2013) Fabrication and properties of nanocrystalline Co0.5FeNiCrTi0.5 high entropy alloy by MA-SPS technique. Mater Des 44:535–539

Zhang Y, Zuo TT, Tang Z, Gao MC, Dahmen KA, Liaw PK, Lu ZP (2014) Microstructures and properties of high-entropy alloys. Prog Mater Sci 61:1–93

Fu ZQ, Chen WP, Wen HM, Chen Z, Lavernia EJ (2015) Effects of Co and sintering method on microstructure and mechanical behavior of a high-entropy Al0.6NiFeCrCo alloy prepared by powder metallurgy. J Alloys Compd 646:175–182

Varalakshmi S, Kamaraj M, Murty BS (2010) Processing and properties of nanocrystalline CuNiCoZnAlTi high entropy alloys by mechanical alloying. Mater Sci Eng, A 527:1027–1030

Tong CJ, Chen MR, Chen SK, Yeh JW, Shun TT, Lin SJ et al (2005) Mechanical performance of the Al x CoCrCuFeNi high-entropy alloy system with multiprincipal elements. Metall Mater Trans A 36:1263–1271

Huang PK, Yeh JW, Shun TT, Chen SK (2004) Multi-principal-element alloys with improved oxidation and wear resistance for thermal spray coating. Adv Eng Mater 6:74–78

Zhang KB, Fu ZY, Zhang JY, Wang WM, Lee SW, Niihara K (2010) Characterization of nanocrystalline CoCrFeNiTiAl high-entropy solid solution processed by mechanical alloying. J Alloys Compd 495:33–38

Ji W, Wang WM, Wang H, Zhang JY, Wang YC, Zhang F, Fu ZY (2015) Alloying behavior and novel properties of CoCrFeNiMn high-entropy alloy fabricated by mechanical alloying and spark plasma sintering. Intermetallics 56:24–27

Fu ZQ, Chen WP, Wen HM, Morgan S, Chen F, Zheng BL, Zhou YZ, Zhang LM, Lavernia EJ (2015) Microstructure and mechanical behavior of a novel Co20Ni20Fe20Al20Ti20 alloy fabricated by mechanical alloying and spark plasma sintering. Mater Sci Eng, A 644:10–16

Fu ZQ, Chen WP, Wen HM, Zhang DL, Chen Z, Zheng BL et al (2016) Microstructure and strengthening mechanisms in an FCC structured single-phase nanocrystalline Co25Ni25Fe25Al7.5Cu17.5 high-entropy alloy. Acta Mater 107:59–71

Zhang KB, Fu ZY, Zhang JY, Wang WM, Wang H, Wang YC, Zhang QJ, Shi J (2009) Nanocrystalline CoCrFeNiCuAl high-entropy solid solution synthesized by mechanical alloying. J Alloys Compd 485:L31–L34

Chen YL, Hu YH, Tsai CW, Hsieh CA, Kao SW, Yeh JW et al (2009) Alloying behavior of binary to octonary alloys based on Cu–Ni–Al–Co–Cr–Fe–Ti–Mo during mechanical alloying. J Alloys Compd 477:696–705

Munir ZA, Anselmi-Tamburini U, Ohyanagi M (2006) The effect of electric field and pressure on the synthesis and consolidation of materials: a review of the spark plasma sintering method. J Mater Sci 41:763–777. doi:10.1007/s10853-006-6555-2

Ding HY (2013) Hong entropy Ti20Zr20Cu20Ni20Be20 bulk metallic glass. J Non-Cryst Solids 364:9–12

Li HF, Xie XH, Zhao K, Wang YB, Zheng YF, Wang WH et al (2013) In vitro and in vivo studies on biodegradable CaMgZnSrYb high-entropy bulk metallic glass. Acta Biomater 9:8561–8573

Qi TL, Li YH, Takeuchi A, Xie GQ, Miao HT, Zhang W (2015) Soft magnetic Fe25Co25Ni25(B, Si)25 high entropy bulk metallic glasses. Intermetallics 66:8–12

Huo JT, Huo LS, Li JW, Men H, Wang XM, Inoue A, Chang CT, Wang JQ, Li RW (2015) High-entropy bulk metallic glasses as promising magnetic refrigerants. J Appl Phys 117:073902

Takeuchi A, Chen N, Wada T, Yokoyama Y, Kato H, Inoue A et al (2011) Pd20Pt20Cu20Ni20P20 high-entropy alloy as a bulk metallic glass in the centimeter. Intermetallics 19:1546–1554

Kang DH, Zhang H, Yoo HB, Lee HH, Lee S, Lee GW et al (2014) Interfacial free energy controlling glass-forming ability of Cu–Zr alloys. Sci Rep 4:5167

Pauly S, Gorantla S, Wang G, Kühn U, Eckert J (2010) Transformation-mediated ductility in CuZr-based bulk metallic glasses. Nat Mater 9:473–477

Tomolya K, Janovszky D, Sycheva A, Sveda M, Ferenczi T, Roósz A (2015) Peculiarities of ball-milling induced crystalline-amorphous transformation in Cu–Zr–Al–Ni–Ti alloys. Intermetallics 65:117–121

Yan HH, Hu Y, Yan ZJ, Zheng XH, Li YT (2012) Microstructure evolution of Zr50Cu18Ni17Al10Ti5 bulk metallic glass during cold-rolling. J Mater Sci Technol 28:756–760

Chieh TC, Chu J, Liu CT, Wu JK (2003) Corrosion of Zr52.5Cu17.9Ni14.6Al10Ti5 bulk metallic glasses in aqueous solutions. Mater Lett 57:3022–3025

Baldenebro-Lopez FJ, Herrera-Ramírez JM, Arredondo-Rea SP, Gómez-Esparza CD, Martínez-Sánchez R (2015) Simultaneous effect of mechanical alloying and arc-melting processes in the microstructure and hardness of an AlCoFeMoNiTi high-entropy alloy. J Alloys Compd 643:S250–S255

Guinier A (1963) X-ray diffraction in crystals, imperfect crystals and amorphous bodies. WH Freeman, San Francisco, pp 72–81

Sharma S, Suryanarayana C (2008) Effect of Nb on the glass-forming ability of mechanically alloyed Fe–Ni–Zr–B alloys. Scr Mater 58:508–511

Yu P, Bai HY, Tang MB, Wang WL (2005) Excellent glass-forming ability in simple Cu50Zr50-based alloys. J Non-Cryst Solids 351:1328–1332

Cui X, Zhang QD, Li XY, Zu FQ (2016) Dependence of GFA and thermal stability of the Cu50Zr50 alloy on temperature-functioned different liquid states. Intermetallics 73:79–85

Zhang PN, Li JF, Hu Y, Zhou YH (2008) Effect of rolling on the microstructure and mechanical property of Zr52.5Cu17.9Ni14.6Al10Ti5 bulk metallic glass. J Alloys Compd 462:88–93

Pekarskaya E, Löffler JF, Johnson WL (2003) Microstructural studies of crystallization of a Zr-based bulk metallic glass. Acta Mater 51:4045–4057

Takeuchi A, Inoue A (2005) Classification of bulk metallic glasses by atomic size dierence, heat of mixing and period of constituent elements and its application to characterization of the main alloying element. Mater Trans 462:2817–2829

Tomolya K, Janovszky D, Janvari T, Sycheva A, Tranta F, Solyom J, Ferenczi T, Roosz A (2012) Consolidation of Cu58Zr42 amorphous/nanocrystalline powders by PM. J Alloys Compd 536S:S154–S158

Li C, Li JC, Zhao M, Jiang Q (2009) Effect of alloying elements on microstructure and properties of multiprincipal elements high-entropy alloys. J Alloys Compd 475:752–757

Ke GY, Chen SK, Hsu T, Yeh JW (2006) FCC and BCC equivalents in as-cast solid solutions of AlxCoyCrzCu0.5FevNiw high-entropy alloys. Ann Chim Sci Mater 31:669–683

Senkov ON, Miracle DB (2001) Effect of the atomic size distribution on glass forming ability of amorphous metallic alloys. Mater Res Bull 36:2183–2198

Zhou YJ, Zhang Y, Wang FJ, Wang YL, Chen GL (2008) Effect of Cu addition on the microstructure and mechanical properties of AlCoCrFeNiTi0.5 solid-solution alloy. J Alloys Compd 466:201–204

Cheng JB, Liang XB, Xu BS (2014) Effect of Nb addition on the structure and mechanical behaviors of CoCrCuFeNi high-entropy alloy coatings. Surf Coat Technol 240:184–190

Standard practice for calculation of corrosion rates and related information from electrochemical measurements. Designation: G 102–189 (Reapproved 1999)

Tam MK, Pang SJ, Shek CH (2007) Corrosion behavior and glass-forming ability of Cu–Zr–Al–Nb alloys. J Non-Cryst Solids 353:3596–3599

Acknowledgements

This work was supported by the financial support from the Natural Science Foundation of China [No. 51671095], and the Key Research Development Program of Shandong Province of China [2015GGx102016].

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ge, W., Wang, Y., Shang, C. et al. Microstructures and properties of equiatomic CuZr and CuZrAlTiNi bulk alloys fabricated by mechanical alloying and spark plasma sintering. J Mater Sci 52, 5726–5737 (2017). https://doi.org/10.1007/s10853-017-0808-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-017-0808-0