Abstract

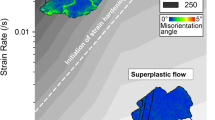

The application of grain boundary engineering (GBE) techniques to enhance the physical and mechanical properties of Ni-based superalloys could potentially increase the efficiency of turbine engines. Compared to traditional GBE processes that require multiple iterations of room temperature deformation followed by annealing, novel techniques for GBE based on the optimization of the thermal–mechanical processing parameters exhibit more potential for producing complex-shaped Ni-based superalloys components. To date, the formation and microstructural evolution of Σ3 boundaries during thermal–mechanical processing have yet to be fully understood. In this investigation, the effects of deformation texture and strain were systematically investigated in an advanced Ni-based superalloy, RR1000. Using various strains and annealing temperatures, the effects of recrystallization and texturing were quantified. Although texturing was often associated with recrystallization that caused the length fraction of Σ3 boundaries to decrease, the formation of Goss type texture during deformation was found to promote the formation of Σ3 boundaries upon annealing when compared to deformation texturing 〈111〉 parallel to the rolling direction.

Similar content being viewed by others

References

Subramanian PR, Mendiratta MG, Dimiduk DM (1996) The development of Nb-based advanced intermetallic alloys for structural applications. J Miner Met Mater Soc 48:33–38

Jackson MR, Bewlay BP, Rowe RG, Skelly DW, Lipsitt HA (1996) High-temperature refractory metal-intermetallic composites. J Miner Met Mater Soc 48:39–44

Zhang JX, Harada H, Ro Y, Koizumi Y, Kobayashi T (2008) Thermomechanical fatigue mechanism in a modern single crystal nickel base superalloy TMS-82. Acta Mater 56:2975–2987

Rémy L, Alam A, Haddar N, Köster A, Marchal N (2007) Growth of small cracks and prediction of lifetime in high-temperature alloys. Mater Sci Eng A 468:40–50

MacLachlan DW, Knowles DM (2001) Modelling and prediction of the stress rupture behaviour of single crystal superalloys. Mater Sci Eng A 302:275–285

Ghosh RN, Curtis RV, McLean M (1990) Creep deformation of single crystal superalloys—modelling the crystallographic anisotropy. Acta Metall Mater 38:1977–1992

Reed RC (2006) The superalloys: fundamentals and applications. Cambridge University Press, New York

Jha SK, Caton MJ, Larsen JM (2007) A new paradigm of fatigue variability behavior and implications for life prediction. Mater Sci Eng A 468:23–32

Przybyla CP, McDowell DL (2010) Microstructure-sensitive extreme value probabilities for high cycle fatigue of Ni-base superalloy IN100. Int J Plast 26:372–394

McDowell DL, Dunne FPE (2010) Microstructure-sensitive computational modeling of fatigue crack formation. Int J Fatigue 32:1521–1542

Barrie RL, Gabb TP, Telesman J, Kantzos PT, Prescenzi A, Biles T, Bonacuse PJ (2008) Effectiveness of shot peening in suppressing fatigue cracking at non-metallic inclusions in Udimet® 720. Mater Sci Eng A 474:71–81

Tong J, Dalby S, Byrne J, Henderson MB, Hardy MC (2001) Creep, fatigue and oxidation in crack growth in advanced nickel base superalloys. Int J Fatigue 23:897–902

Furrer D, Fecht H (1999) Ni-based superalloys for turbine discs. J Miner Met Mater Soc 51:14–17

Detrois M, Antonov S, Helmink RC, Tin S (2014) Precipitate phase stability in tate phase SBase superalloys. J Miner Met Mater Soc 66:2478–2485

Antonov S, Detrois M, Helmink RC, Tin S (2015) Precipitate phase stability and compositional dependence on alloying additions in γ recipit Ni-base superalloys. J Alloys Compd 626:76–86

Lin P, Palumbo G, Erb U, Aust KT (1995) Influence of grain boundary character distribution on sensitization and intergranular corrosion of alloy 600. Scr Metall Mater 33:1387–1392

Thaveeprungsriporn V, Was GS (1997) The role of coincidence-site-lattice boundaries in creep of Ni-16Cr-9Fe at 360°C. Metall Mater Trans A 28:2101–2112

Otto F, Payton EJ, Frenzel J, Eggeler G (2012) The effectiveness of coincidence site lattice criteria in predicting creep cavitation resistance. J Mater Sci 47:2915–2927. doi:10.1007/s10853-011-6124-1

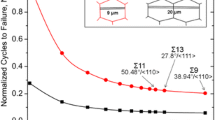

Gao Y, Kumar M, Nalla RK, Ritchie RO (2005) High-cycle fatigue of nickel-based superalloy ME3 at ambient and elevated temperatures: role of grain-boundary engineering. Metall Mater Trans A 36:3325–3333

Detor AJ, Deal AD, Hanlon T (2012) Grain boundary engineering alloy 706 for improved high temperature performance. Superalloys 2012:873–880

Watanabe T (2011) Grain boundary engineering: historical perspective and future prospects. J Mater Sci 46:4095–4115. doi:10.1007/s10853-011-5393-z

Kumar M, King WE, Schwartz AJ (2000) Modifications to the microstructural topology in F.C.C. materials through thermomechanical processing. Acta Mater 48:2081–2091

Palumbo G, Lehockey EM, Lin P (1998) Applications for grain boundary engineered materials. J Miner Met Mater Soc 50:40–43

Randle V (2004) Twinning-related grain boundary engineering. Acta Mater 52:4067–4081

Schuh CA, Kumar M, King WE (2003) Analysis of grain boundary networks and their evolution during grain boundary engineering. Acta Mater 51:687–700

Randle V (1996) The role of the coincidence site lattice in grain boundary engineering. The Institute of Materials, London

Lee S-L, Richards NL (2005) The effect of single-step low strain and annealing of nickel on grain boundary character. Mater Sci Eng, A 390:81–87

Palumbo G, Aust KT (1992) Special properties of Σ grain boundaries. In: Wolf D, Yip S (eds) Materials interfaces: atomic-level structure and properties. Chapman & Hall, London, pp 190–207

Detrois M, Rotella J, Goetz RL, Helmink RC, Tin S (2015) Grain boundary engineering of powder processed Ni-base superalloy RR1000: influence of the deformation parameters. Mater Sci Eng A 627:95–105

Detrois M, Goetz RL, Helmink RC, Tin S (2015) Modeling the effect of thermal–mechanical processing parameters on the density and length fraction of twin boundaries in Ni-base superalloy RR1000. Mater Sci Eng A 647:157–162

Li B, Tin S (2014) The role of deformation temperature and strain on grain boundary engineering of Inconel 600. Mater Sci Eng A 603:104–133

Souaï N, Bozzolo N, Nazé L, Chastel Y, Logé R (2010) About the possibility of grain boundary engineering via hot-working in a nickel-base superalloy. Scr Mater 62:851–854

Mahajan S, Pande CS, Imam MA, Rath BB (1997) Formation of annealing twins in f.c.c. crystals. Acta Mater 45:2633–2638

Meyers MA, Vohringer O, Lubarda VA (2001) The onset of twinning in metals: a constitutive description. Acta Mater 49:4025–4039

Wang W, Lartigue-Korinek S, Brisset F, Helbert AL, Bourgon J, Baudin T (2015) Formation of annealing twins during primary recrystallization of two low stacking fault energy Ni-based alloys. J Mater Sci 50:2167–2177. doi:10.1007/s10853-014-8780-4

Rout M, Pal SK, Singh SB (2015) Cross rolling: a metal forming process. In: Davim JP (ed) Modern manufacturing engineering, materials forming, machining and tribology. Springer, Zurich, pp 41–64

Collins DM, Conduit BD, Stone HJ, Hardy MC, Conduit GJ, Mitchell RJ (2013) Grain growth behaviour during near-γ’ solvus thermal exposures in a polycrystalline nickel-base superalloy. Acta Mater 61:3378–3391

Field DP, Bradford LT, Nowell MM, Lillo TM (2007) The role of annealing twins during recrystallization of Cu. Acta Mater 55:4233–4241

Hirsch J, Lucke K (1988) Mechanism of deformation and development of rolling textures in polycrystalline F.C.C. metals—I. Description of rolling texture development in homogeneous CuZn alloys. Acta Metall 36:2863–2882

Zhou Y, Neale KW, Toth LS (1991) On the ideal orientations of rolling textures for FCC polycrystals. Textures Microstruct 14–18:1055–1060

Pande CS, Imam MA, Rath BB (1990) Study of annealing twins in FCC metals and alloys. Metall Mater Trans A 21:2891–2896

Randle V (1999) Mechanism of twinning-induced grain boundary engineering in low stacking-fault energy materials. Acta Mater 47:4187–4196

Birosca S, Di Gioacchino F, Stekovic S, Hardy M (2014) A quantitative approach to study the effect of local texture and heterogeneous plastic strain on the deformation micromechanism in RR1000 nickel-based superalloy. Acta Mater 74:110–124

Jin Z-H, Gumbsch P, Ma E, Albe K, Lu K, Hahn H, Gleiter H (2006) The interaction mechanism of screw dislocations with coherent twin boundaries in different face-centred cubic metals. Scr Mater 54:1163–1168

Jin Z-H, Gumbsch P, Albe K, Ma E, Lu K, Gleiter H, Hahn H (2008) Interactions between non-screw lattice dislocations and coherent twin boundaries in face-centered cubic metals. Acta Mater 56:1126–1135

Randle V, Owen G (2006) Mechanisms of grain boundary engineering. Acta Mater 54:1777–1783

Akhiani H, Nezakat M, Sanayei M, Szpunar J (2015) The effect of thermo-mechanical processing on grain boundary character distribution in Incoloy 800H/HT. Mater Sci Eng A 626:51–60

Schwartz AJ, King WE, Kumar M (2006) Influence of processing method on the network of grain boundaries. Scr Mater 54:963–968

Fullman RL, Fisher JC (1951) Formation of annealing twins during grain growth. J Appl Phys 22:1350–1355

Jin Y, Lin B, Bernacki M, Rohrer GS, Rollett AD, Bozzolo N (2014) Annealing twin development during recrystallization and grain growth in pure nickel. Mater Sci Eng A 597:295–303

Cahoon JR, Li Q, Richards NL (2009) Microstructural and processing factors influencing the formation of annealing twins. Mater Sci Eng A 526:56–61

Acknowledgements

Financial support for this work was provided by Rolls-Royce Corporation and NSF CMMI-1334998.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Detrois, M., Goetz, R.L., Helmink, R.C. et al. The role of texturing and recrystallization during grain boundary engineering of Ni-based superalloy RR1000. J Mater Sci 51, 5122–5138 (2016). https://doi.org/10.1007/s10853-016-9815-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-9815-9