Abstract

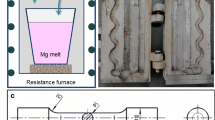

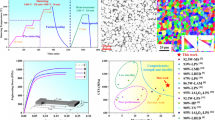

In the present study, an attempt is made for the first time to reinforce long-period stacking ordered (LPSO) MgY1.06Zn0.76Al0.42 (at.%) alloy with 0.5, 1.0, and 1.5 vol% of nano-Al2O3 particles to form nanocomposites. Microstructure characterization revealed the ability of nano-Al2O3 in inhibiting the formation of 14H LPSO phases in the nanocomposites during solidification. Homogenization at 723 K (450 °C) for 2 h led to the subsequent precipitation of fine Mg-Y-Zn-Al precipitates (≤1 µm) in the nanocomposites. The fine Mg-Y-Zn-Al precipitates and nano-Al2O3 particles were established to be active in promoting dynamic recrystallization (DRX) of α-Mg via particle-simulated nucleation during extrusion, which was responsible for weakening the basal texture in the nanocomposites and improving failure strain. As a result, failure strain was significantly increased from 10.8 % in the monolithic alloy to beyond 15 % in the nanocomposites with the highest strength among nanocomposites achieved in NC5 (nanocomposite reinforced with 0.5 vol% of nano-Al2O3 particles).

Similar content being viewed by others

References

Kim JJ, Han DS (2008) Recent development and applications of magnesium alloys in the Hyundai and Kia Motors Corporation. Mater Trans 49:894–897

Blawert C, Hort N, Kainer K (2004) Automotive applications of magnesium and its alloys. Trans Indian Inst Met 57:397–408

Gándara MJF (2011) Recent growing demand for magnesium in the automotive industry. Materiali in tehnologije 45:633–637

Kawamura Y, Hayashi K, Inoue A, Masumoto T (2001) Rapidly solidified powder metallurgy Mg97Zn1Y2Alloys with excellent tensile yield strength above 600 MPa. Mater Trans 42:1171–1174

Yoshimoto S, Yamasaki M, Kawamura Y (2006) Microstructure and mechanical properties of extruded Mg-Zn-Y alloys with 14H long period ordered structure. Mater Trans 47:959

Kim J, Kawamura Y (2013) Influence of rare earth elements on microstructure and mechanical properties of Mg97Zn1Y1RE1 Alloys. Mater Sci Eng A 573:62–66

Lu F, Ma A, Jiang J, Yang D, Zhou Q (2012) Review on long-period stacking-ordered structures in Mg-Zn-RE alloys. Rare Met 31:303–310

Luo AA (2013) Magnesium casting technology for structural applications. J Magnes Alloys 1:2–22

XingHe T, How WCK, Weng JCK, Onn RKW, Gupta M (2015) Development of high-performance quaternary LPSO Mg–Y–Zn–Al alloys by disintegrated melt deposition technique. Mater Des 83:443–450

Tan X, Chee KHW, Chan KWJ, Kwok WOR, Gupta M (2015) Effect of homogenization on enhancing the failure strain of high strength quaternary LPSO Mg–Y–Zn–Al alloy. Mater Sci Eng A 644:405–412

Paramsothy M, Tan X, Chan J, Kwok R, Gupta M (2012) Al2O3 nanoparticle addition to concentrated magnesium alloy AZ81: enhanced ductility. J Alloy Compd 545:12–18

Paramsothy M, Chan J, Kwok R, Gupta M (2011) The synergistic ability of Al2O3 nanoparticles to enhance mechanical response of hybrid alloy AZ31/AZ91. J Alloy Compd 509:7572–7578

Hassan S, Gupta M (2005) Development of high performance magnesium nano-composites using nano-Al2O3 as reinforcement. Mater Sci Eng A 392:163–168

Nguyen QB, Gupta M (2010) Enhancing mechanical response of AZ31B using Cu+ nano-Al2O3 addition. Mater Sci Eng A 527:1411–1416

Mounib M, Pavese M, Badini C, Lefebvre W, Dieringa H (2014) Reactivity and Microstructure of Al2O3-Reinforced Magnesium-Matrix Composites. Advances in Materials Science and Engineering 2014

Alam ME, Hamouda AMS, Gupta M (2013) Microstructure, thermal and mechanical response of AZ51/Al2O3 nanocomposite with 2 wt% Ca addition. Mater Des 50:1–6

Nguyen Q, Gupta M (2008) Enhancing compressive response of AZ31B magnesium alloy using alumina nanoparticulates. Compos Sci Technol 68:2185–2192

Hassan S, Gupta M (2008) Effect of submicron size Al2O3 particulates on microstructural and tensile properties of elemental Mg. J Alloy Compd 457:244–250

Yang W-P, Guo X-F (2011) High strength magnesium alloy with α-Mg and W-phase processed by hot extrusion. Trans Nonferrous Metals Soc China 21:2358–2364

Lee JY, Kim DH, Lim HK, Kim DH (2005) Effects of Zn/Y ratio on microstructure and mechanical properties of Mg-Zn-Y alloys. Mater Lett 59:3801–3805

Ball E, Prangnell P (1994) Tensile-compressive yield asymmetries in high strength wrought magnesium alloys. Scr Metall Mater 31:111–116

Hirano M, Yamasaki M, Hagihara K, Higashida K, Kawamura Y (2010) Effect of extrusion parameters on mechanical properties of Mg97Zn1Y2 alloys at room and elevated temperatures. Mater Trans 51:1640–1647

Meenashisundaram GK, Gupta M (2015) Synthesis and characterization of high performance low volume fraction TiC reinforced Mg nanocomposites targeting biocompatible/structural applications. Mater Sci Eng A 627:306–315

Habibi MK, Joshi SP, Gupta M (2010) Hierarchical magnesium nano-composites for enhanced mechanical response. Acta Mater 58:6104–6114

Kawamura Y, Yamasaki M (2007) Formation and mechanical properties of Mg97Zn1RE2 alloys with long-period stacking ordered structure. Mater Trans 48:2986–2992

Wang J, Song P, Huang S, Pan F (2013) High-strength and good-ductility Mg–RE–Zn–Mn magnesium alloy with long-period stacking ordered phase. Mater Lett 93:415–418

Oñorbe E, Garcés G, Dobes F, Pérez P, Adeva P (2013) High-temperature mechanical behavior of extruded Mg-Y-Zn Alloy containing LPSO phases. Metall Mater Trans A 44:2869–2883

Tong LB, Li XH, Zhang HJ (2013) Effect of long period stacking ordered phase on the microstructure, texture and mechanical properties of extruded Mg–Y–Zn alloy. Mater Sci Eng A 563:177–183

Paramsothy M, Tan X, Chan J, Kwok R, Gupta M (2013) Carbon nanotube addition to concentrated magnesium alloy AZ81: enhanced ductility with occasional significant increase in strength. Mater Des 45:15–23

Nguyen QB, Tun KS, Chan J, Kwok R, Kuma JV, Phung TH et al (2012) Simultaneous effect of nano-Al2O3 and micrometre Cu particulates on microstructure and mechanical properties of magnesium alloy AZ31. Mater Sci Technol 28:227–233

Acknowledgements

The authors wish to acknowledge the funding support given by Singapore Technologies Kinetics Ltd and Singapore Economic Development Board under the Industrial Post-Graduate Programme (R 265 000 456 592) for carrying out this research work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tan, X., Chee, W.K.H., Chan, J.K.W. et al. Stretching the engineering strain of high strength LPSO quaternary Mg-Y-Zn-Al alloy via integration of nano-Al2O3 . J Mater Sci 51, 4160–4168 (2016). https://doi.org/10.1007/s10853-016-9742-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-9742-9