Abstract

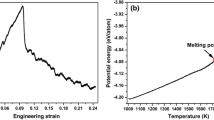

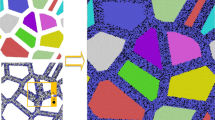

Creep phenomenon is a common mechanical behavior in nanocrystalline nickel (Ni) at high temperature that may affect component function and lead to material failure. In this paper, we systematically study the effects of temperature, stress, and grain size (GS) on creep behavior at high temperature in nanocrystalline Ni by molecular dynamics simulation. Three nanocrystalline Ni models with different GS and a single-crystal Ni model are built for creep behavior simulation. Stress exponent, GS exponent and microstructure characteristics during creep simulation are used to describe steady-state creep mechanism. An obvious creep phenomenon is observed in nanocrystalline Ni, but not in single-crystal Ni; primary creep and steady-state creep phenomenon both occur in nanocrystalline Ni during creep simulation. With increase of temperature and stress level, decrease of GS, creep mechanisms are discovered to change from (1) lattice diffusion and grain boundary (GB) sliding to (2) GB diffusion and GB sliding and then to (3) dislocation nucleation. The similar creep mechanism transition tendency is also found in smaller GS sample at lower temperature. The variation of stress exponent and GS exponent obtained from the simulation results is consistent with creep mechanism theory.

Similar content being viewed by others

References

Gleiter H (1995) Nanocrystalline Materials. Int Mater Rev 40:41–64

Gleiter H (2000) Nanostructured materials: basic concepts and microstructure. Acta Mater 48:1–29

Kumar KS, Swygenhoven HV, Suresh S (2003) Mechanical behavior of nanocrystalline metals and alloys. Acta Mater 51:5743–5774

Meyers MA, Mishra A, Benson DJ (2006) Mechanical properties of nanocrystalline materials. Prog Mater Sci 51:427–556

Wang N, Wang ZR, Aust KT, Erb U (1997) Room temperature creep behavior of nanocrystalline nickel produced by an electrodeposition technique. Mater Sci Eng A 237:150–158

Yin WM, Whang SH, Mirshams R, Xiao CH (2001) Creep behavior of nanocrystalline nickel at 290 and 373 K. Mater Sci Eng A 301:18–22

Wang CL, Lai YH, Huang JC, Nieh TG (2010) Creep of nanocrystalline nickel: a direct comparison between uniaxial and nanoindentation creep. Scripta Mater 62:175–178

Alder BJ, Wainwright TE (2004) Phase Transition for a Hard Sphere System. J Chem Phys 27:1208–1209

Keblinski P, Wolf D, Gleiter H (1998) Molecular-dynamics simulation of grain-boundary diffusion creep. Interface Sci 6:205–212

Yamakov V, Wolf D, Phillpot SR, Gleiter H (2002) Grain-boundary diffusion creep in nanocrystalline palladium by molecular-dynamics simulation. Acta Mater 50:61–73

Millett PC, Desai T, Yamakov V, Wolf D (2008) Atomistic simulations of diffusional creep in a nanocrystalline body-centered cubic material. Acta Mater 56:3688–3698

Wang YJ, Ishii A, Ogata S (2011) Transition of creep mechanism in nanocrystalline metals. Phys Rev B 2025:129–139

Wang YJ, Ishii A, Ogata S (2012) Grain Size Dependence of Creep in Nanocrystalline Copper by Molecular Dynamics. Mater Trans 53:156–160

Bhatia MA, Mathaudhu SN, Solanki KN (2015) Atomic-scale investigation of creep behavior in nanocrystalline Mg and Mg-Y alloys. Acta Mater 99:382–391

Jiao S, Kulkarni Y (2015) Molecular dynamics study of creep mechanisms in nanotwinned metals. Comput Mater Sci 110:254–260

Swygenhoven HV, Caro A (1998) Plastic behavior of nanophase metals studied by molecular dynamics. Phys Rev B 58:11246–11251

Swygenhoven HV, Caro A (1997) Plastic behavior of nanophase Ni: a molecular dynamics computer simulation. Appl Phys Lett 71:1652–1654

Wolf D, Yamakov V, Phillpot SR, Mukherjee A, Gleiter H (2005) Deformation of nanocrystalline materials by molecular-dynamics simulation: relationship to experiments? Acta Mater 53:1–40

Yamakov V, Wolf D, Phillpot SR, Mukherjee AK, Gleiter H (2004) Deformation-mechanism map for nanocrystalline metals by molecular-dynamics simulation. Nat Mater 3:43–47

Mukherjee AK, Bird JE, Dorn JE (1969) Experimental Correlations for High-Temperature Creep. Trans. ASM 62:155–179

Coble RL (1963) A Model for Boundary Diffusion Controlled Creep in Polycrystalline Materials. J Appl Phys 34:1679–1682

Herring C (1950) Diffusional Viscosity of a Polycrystalline Solid. J Appl Phys 21:437–445

Nabarro FRN (1948) Report of a Conference on the Strength of Solids. Physical Society 75

Bardeen J (1949) Diffusion in Binary Alloys. Phys Rev 76:1403–1405

Li CM (1978) Physical chemistry of some microstructural phenomena. Metall Trans A 9:1353–1380

Gifkins RC (1968) Diffusional Creep Mechanisms. J Am Ceram Soc 51:69–72

Lüthy H, White RA, Sherby OD (1979) Grain boundary sliding and deformation mechanism maps. Materials Science and Engineering 39:211–216

Ashby MF, Jones DRH (1995) Engineering materials 1. An Introduction to Properties, Applications and design. Elsevier, London, pp 274–323

Blum W, Zeng XH (2009) A simple dislocation model of deformation resistance of ultrafine-grained materials explaining Hall-Petch strengthening and enhanced strain rate sensitivity. Acta Mater 57:1966–1974

Weertman J (1955) Theory of steady-state creep based on dislocation climb. J Appl Phys 26:1213–1217

Weertman J (1957) Steady-State creep of crystals. J Appl Phys 28:1185–1189

Weertman J (1957) Steady-State creep through dislocation climb. J Appl Phys 28:362–364

Foiles SM, Baskes MI, Daw MS (1986) Embedded-atom-method functions for the fcc metals Cu, Ag, Au, Ni, Pd, Pt, and their alloys. Phys Rev B 33:7983–7991

Parrinello M, Rahman A (1981) Polymorphic transitions in single crystals: a new molecular dynamics method. J Appl Phys 52:7182–7190

Parrinello M, Rahman A (1982) Strain fluctuations and elastic constants. J Chem Phys 76:2662–2666

Hoover WG (1985) Canonical dynamics: equilibrium phase-space distribution. Phys Rev A 31:1695–1697

Nosé S (1984) A unified formulation of the constant temperature molecular dynamics methods. J Chem Phys 81:511–519

Plimpton S (1995) Fast parallel algorithms for short-range molecular dynamics. J Comput Phys 117:1–19

Li J (2003) AtomEye: an efficient atomistic configuration viewer. Modelling Simul Mater Sci Eng 11:173–177

Kelchner CL, Plimpton SJ, Hamilton JC (1998) Dislocation nucleation and defect structure during surface indentation. Phys Rev B 58:11085–11088

Poirier JP (1985) Creep of crystals: high-temperature deformation processes in metals. Cambridge University Press, Cambridge, pp 76–93

Asaro RJ, Suresh S (2005) Mechanistic models for the activation volume and rate sensitivity in metals with nanocrystalline grains and nano-scale twins. Acta Mater 53:3369–3382

Acknowledgements

The work was supported by the State Key Program of National Natural Science Foundation of China (Grant No. 11532010) and National Natural Science Foundation of China (Grant Nos. 11102139 and 11472195).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nie, K., Wu, WP., Zhang, XL. et al. Molecular dynamics study on the grain size, temperature, and stress dependence of creep behavior in nanocrystalline nickel. J Mater Sci 52, 2180–2191 (2017). https://doi.org/10.1007/s10853-016-0506-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0506-3