Abstract

The main objective of the present study was to investigate the influence of reaction temperature for hydrothermal carbonization (HTC) of holocellulose which came from the forestry residues, miscellaneous wood fibers. The temperatures of HTC ranged from 200 to 240 °C and the reaction time was controlled at 8 h. The structural, chemical, and thermal properties of holocellulose-derived hydrochar were characterized using scanning electron microscopy, X-ray diffraction, nitrogen adsorption, Fourier transform infrared spectroscopy, elemental analysis, and TGA. According to the results, reaction temperature has a significant influence on the properties of the holocellulose-derived hydrochars. With increasing the HTC temperature, the wood-cellulated holocellulose converts into micro/nano carbon spheres gradually along with the disappearing of cellulosic crystalline region. The chemical composition of the hydrochars tends to be stable with elevating the temperature. The resultant hydrochar products with high degree of aromatization possess a large amount of oxygen-containing functional groups. Moreover, the energy content and thermostability of the hydrochars are considerably improved with increasing the HTC temperature. The attained results enable properties prediction of holocellulose-derived hydrochar from these forestry residues and contribute to understand the influence of process conditions on HTC of crude biomass.

Similar content being viewed by others

References

Robbins MP, Evans G, Valentine J, Donnison IS, Allison GG (2012) New opportunities for the exploitation of energy crops by thermochemical conversion in Northern Europe and the UK. Prog Energy Combust Sci 38:138–155

Gao Y, Wang X-H, Yang H-P, Chen H-P (2012) Characterization of products from hydrothermal treatments of cellulose. Energy 42:457–465

Liu WJ, Jiang H, Yu HQ (2015) Development of Biochar-Based Functional Materials: toward a sustainable platform carbon material. Chem Rev 115:12251–12285

Titirici MM, Antonietti M (2010) Chemistry and materials options of sustainable carbon materials made by hydrothermal carbonization. Chem Soc Rev 39:103–116

Sevilla M, Fuertes AB, Mokaya R (2011) High density hydrogen storage in superactivated carbons from hydrothermally carbonized renewable organic materials. Energy Environ Sci 4:1400–1410

Sevilla M, Maciá-Agulló JA, Fuertes AB (2011) Hydrothermal carbonization of biomass as a route for the sequestration of CO2: chemical and structural properties of the carbonized products. Biomass Bioenergy 35:3152–3159

Román S, Nabais JMV, Laginhas C, Ledesma B, González JF (2012) Hydrothermal carbonization as an effective way of densifying the energy content of biomass. Fuel Process Technol 103:78–83

Sevilla M, Fuertes AB (2009) Chemical and structural properties of carbonaceous products obtained by hydrothermal carbonization of saccharides. Chem Eur J 15:4195–4203

Sevilla M, Fuertes AB (2009) The production of carbon materials by hydrothermal carbonization of cellulose. Carbon 47:2281–2289

Falco C, Baccile N, Titirici M-M (2011) Morphological and structural differences between glucose, cellulose and lignocellulosic biomass derived hydrothermal carbons. Green Chem 13:3273–3281

Falco C, Sieben JM, Brun N, Sevilla M, van der Mauelen T, Morallon E, Cazorla-Amorós D, Titirici MM (2013) Hydrothermal carbons from hemicellulose-derived aqueous hydrolysis products as electrode materials for supercapacitors. ChemSusChem 6:374–382

Titirici M-M, Antonietti M, Baccile N (2008) Hydrothermal carbon from biomass: a comparison of the local structure from poly- to monosaccharides and pentoses/hexoses. Green Chem 10:1204–1212

Parshetti GK, Hoekman SK, Balasubramanian R (2013) Chemical, structural and combustion characteristics of carbonaceous products obtained by hydrothermal carbonization of palm empty fruit bunches. Bioresour Technol 135:683–689

Reza MT, Rottler E, Herklotz L, Wirth B (2015) Hydrothermal carbonization (HTC) of wheat straw: influence of feedwater pH prepared by acetic acid and potassium hydroxide. Bioresour Technol 182:336–344

Xiao L-P, Shi Z-J, Xu F, Sun R-C (2012) Hydrothermal carbonization of lignocellulosic biomass. Bioresour Technol 118:619–623

Erdogan E, Atila B, Mumme J, Reza MT, Toptas A, Elibol M, Yanik J (2015) Characterization of products from hydrothermal carbonization of orange pomace including anaerobic digestibility of process liquor. Bioresour Technol 196:35–42

Funke A, Ziegler F (2011) Heat of reaction measurements for hydrothermal carbonization of biomass. Bioresour Technol 102:7595–7598

Ding LL, Wang ZC, Li YN, Du YL, Liu HQ, Guo YP (2012) A novel hydrochar and nickel composite for the electrochemical supercapacitor electrode material. Mater Lett 74:111–114

Ding LL, Zou B, Li YN, Liu HQ, Wang ZC, Zhao C, Su Y, Guo YP (2013) The production of hydrochar-based hierarchical porous carbons for use as electrochemical supercapacitor electrode materials. Colloids Surf A 423:104–111

Chen Z, Ma LJ, Li SQ, Geng JX, Song Q, Liu J, Wang CL, Wang H, Li J, Qin Z, Li SJ (2011) Simple approach to carboxyl-rich materials through low-temperature heat treatment of hydrothermal carbon in air. Appl Surf Sci 257:8686–8691

Demir-Cakan R, Baccile N, Antonietti M, Titirici M-M (2009) Carboxylate-rich carbonaceous materials via one-step hydrothermal carbonization of glucose in the presence of acrylic acid. Chem Mater 21:484–490

Li X-L, Lou T-J, Sun X-M, Li Y-D (2004) Highly sensitive WO3 hollow-sphere gas sensors. Inorg Chem 43:5442–5449

Hu B, Wang K, Wu LH, Yu SH, Antonietti M, Titirici MM (2010) Engineering carbon materials from the hydrothermal carbonization process of biomass. Adv Mater 22:813–828

Seehra MS, Akkineni LP, Yalamanchi M, Singh V, Poston J (2012) Structural characteristics of nanoparticles produced by hydrothermal pretreatment of cellulose and their applications for electrochemical hydrogen generation. Int J Hydrog Energy 37:9514–9523

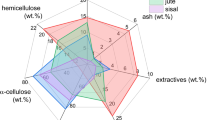

Liu FY, Guo MH (2015) Comparison of the characteristics of hydrothermal carbons derived from holocellulose and crude biomass. J Mater Sci 50:1624–1631. doi:10.1007/s10853-014-8723-0

Chen WS, Yu HP, Liu YX, Chen P, Zhang MX, Hai YF (2011) Individualization of cellulose nanofibers from wood using high-intensity ultrasonication combined with chemical pretreatments. Carbohydr Polym 83:1804–1811

Liu SW, Wang XB, Zhao HJ, Cai WP (2015) Micro/nano-scaled carbon spheres based on hydrothermal carbonization of agarose. Colloids Surf A 484:386–393

Sevilla M, Fuertes AB (2011) Sustainable porous carbons with a superior performance for CO2 capture. Energy Environ Sci 4:1765–1771

Fuertes AB, Sevilla M (2015) Superior capacitive performance of hydrochar-based porous carbons in aqueous electrolytes. ChemSusChem 8:1049–1057

Ding LL, Zou B, Liu HQ, Li YN, Wang ZC, Su Y, Guo YP, Wang XF (2013) A new route for conversion of corncob to porous carbon by hydrolysis and activation. Chem Eng J 225:300–305

Himmelsbach DS, Khalili S, Akin DE (2002) The use of FT-IR microspectroscopic mapping to study the effects of enzymatic retting of flax (Linum usitatissimum L) stems. J Sci Food Agric 82:685–696

Pandey KK, Theagarjan KS (1997) Analysis of wood surfaces and ground wood by diffuse reflectance (DRIFT) and photoacoustic (PAS) Fourier transform infrared spectroscopic techniques. Holz Roh Werkst 55:383–390

Agarwal UP, McSweeny JD, Ralph SA (2011) FT–Raman investigation of milled-wood lignins: softwood hardwood, and chemically modified black spruce lignins. J Wood Chem Technol 31:324–344

Kabyemela BM, Adschiri T, Malaluan RM, Arai K (1999) Glucose and fructose decomposition in subcritical and supercritical water: detailed reaction pathway mechanisms, and kinetics. Ind Eng Chem Res 38:2888–2895

Hoekman SK, Broch A, Robbins C (2011) Hydrothermal carbonization (HTC) of lignocellulosic biomass. Energy Fuels 25:1802–1810

Wiedner K, Naisse C, Rumpel C, Pozzi A, Wieczorek P, Glaser B (2013) Chemical modification of biomass residues during hydrothermal carbonization—What makes the difference, temperature or feedstock? Org Geochem 54:91–100

Sabio E, Álvarez-Murillo A, Román S, Ledesma B (2016) Conversion of tomato-peel waste into solid fuel by hydrothermal carbonization: influence of the processing variables. Waste Manage 47:122–132

Acknowledgements

The authors are thankful for the research funding from National Forestry Industry Research Special Funds for Public Welfare Projects (201504501-1).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, F., Yu, R. & Guo, M. Hydrothermal carbonization of forestry residues: influence of reaction temperature on holocellulose-derived hydrochar properties. J Mater Sci 52, 1736–1746 (2017). https://doi.org/10.1007/s10853-016-0465-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0465-8