Abstract

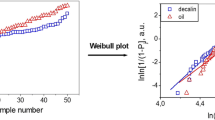

Studies of the potentials of the multi-stage hot-zone drawing technique for enhancing the tensile strength (σ) of ultra-high-molecular-weight polyethylene (UHMWPE) gel-cast highly oriented film threads, the applicability of the Weibull statistics to the σ distribution, and the solvent role in the film thread strength are presented. It is shown that the results of a large number of mechanical measurements for two series of UHMWPE film threads drawn to an ultimate draw ratio (λ) of 120 from xerogels formed from 1.5 % solutions of UHMWPE in decalin or paraffin oil are satisfactorily described by the Weibull model. It is shown that the threads produced are characterised by an average strength σ av = 4.7 GPa and 20 % of the samples have σ = 5.2–6.5 GPa. This is higher than the strength of the commercially available gel-spun oriented UHMWPE fibres of σ = 3.5 GPa. It is found that the solvent nature does not affect the tensile strength of the film threads but exerts a considerable influence on the long-term characteristics.

Similar content being viewed by others

References

Marikhin VA, Myasnikova LP (1996) Structural basis of high-strength high-modulus polymers. In: Fakirov S (ed) Oriented polymer materials. Huthig & Wepf Verlag-Zug, Heidelberg, pp 38–98

Marikhin V, Myasnikova L, Boiko Y, Ivan’kova E, Radovanova E, Yakushev P (2011) Role of reactor powder morphology in producing high-strength high-modulus UHMWPE Fibres. In: Myasnikova L, Lemstra P (eds) Reactor powder morphology. Nova Publishers, Hauppauge, pp 235–294 Chapter 10. ISBN 978-1-61668-592-8

Tanaka F, Okabe T, Okuda H, Kinloch IA, Young RJ (2014) Factors controlling the strength of carbon fibres in tension. Compos Part A 57:88–94

Baikova LG, Pesina TI, Kireenko MF, Tikhonova LV, Kurkjian CR (2015) Strength of optical silica fibres measured in liquid nitrogen. Tech Phys 60:869–872

Zhurkov SN (1965) Kinetic Concept of the Strength of Solids. Int J Fract Mech 1:4311–4332

Zhurkov SN, Levin BY, Savitsky AV (1969) High-strength polymer fibres, Doklady Akademii Nauk USSR 186:132–133 (in Russian)

Zhurkov SN, Abasov SA (1999) The temperature and the time dependence of the strength of polymer yarns. Polym Sci Ser A 41:1276–1282

Tuchkevich VM (1975) Personalia of Serafim Nikolaevich Zhurkov. Int J Fract 11:723–726

Serafim Nikolaevich Zhurkov (May 29, 1905-September 18, 1997) (2005) Phys Solid State 47:797

Budtov VP, Gann LA, Duvakin VA, Myasnikov GD, Marikhin VA, Myasnikova LP (1982) Method of production of axially oriented polyethylene film, State Affairs Committee on Discoveries and Inventions of USSR, Authorship to Invention № 933476 (in Russian)

Weibull W (1951) A statistical distribution function of wide applicability. J Appl Mech 18:293–297

Wilson DM (1997) Statistical tensile strength of Nextel™ 610 and Nextel™ 720 fibres. J Mater Sci 32:2535–2542. doi:10.1023/A:1018538030985

Sun G, Pang JHL, Zhou J, Zhang Y, Zhan Z, Zheng L (2012) A modified Weibull model for tensile strength distribution of carbon nanotube fibres with strain rate and size effects. Appl Phys Lett 101:131905

Sullivan JD, Lauzon PH (1986) Experimental probability estimators for Weibull plots. J Mater Sci Lett 5:1245–1247

Gurvich MR, Dibenedetto AT, Pegoretti A (1997) Evaluation of the statistical parameters of a Weibull distribution. J Mater Sci 32:3711–3716. doi:10.1023/A:1018603118573

Pugno NM, Ruoff RS (2007) Nanoscale Weibull statistics for nanofibers and nanotubes. J Aerosp Eng 20:97–101

Van der Zwaag S (1989) The concept of filament strength and the Weibull modulus. J Test Eval 17:292–298

Bergman B (1984) On the estimation of the Weibull modulus. J Mater Sci Lett 3:689–692

Trustrum K, de Jayatilaka AS (1979) On estimating the Weibull modulus for a brittle material. J Mater Sci 14:1080–1084. doi:10.1007/BF00561290

Klein CA (2007) Characteristic tensile strength and Weibull shape parameter of carbon nanotubes. J Appl Phys 101:124909

De Rosa IM, Kenny JM, Puglia D, Santulli C, Sarasini F (2010) Morphological, thermal and mechanical characterization of okra (Abelmoschus esculentus) fibres as potential reinforcement in polymer composites. Compos Sci Technol 70:116–122

Zhang Y, Wang X, Pan N, Postle R (2002) Weibull analysis of the tensile behavior of fibres with geometrical irregularities. J Mater Sci 37:1401–1406. doi:10.1023/A:1014580814803

Wu HF, Netravali AN (1992) Weibull analysis of strength-length relationships in single Nicalon SiC fibres. J Mater Sci 27:3318–3324. doi:10.1007/BF01116031

Bazant ZP, Le J-L, Bazant MZ (2009) Scaling of strength and lifetime probability distributions of quasibrittle structures based on atomistic fracture mechanics. Proc Acad Sci USA 106:11484–11489

Bazant ZP, Pang S-D (2006) Mechanics-based statistics of failure risk of quasibrittle structures and size effect on safety factors. Proc Acad Sci USA 103:9434–9439

Barber AH, Andrews R, Shaudler LS, Wagner HD (2005) On the tensile strength distribution of multiwalled carbon nanotubes. Appl Phys Lett 87:203106

Roy A, Chakraborty S, Kundu SP, Basak RK, Majumber SB, Adhikari B (2012) Improvement in mechanical properties of jute fibres through mild alkali treatment as demonstrated by utilisation of the Weibull distribution model. Bioresour Technol 107:222–228

de Jayatilaka AS, Trustrum K (1977) Statistical approach to brittle fracture. J Mater Sci 12:1426–1430.10.1007/BF00540858

Kavesh S, Prevorsek DK (1982) US Patent No 4,413,110

Marikhin VA (1963) A simple method of receiving structure-free replicas for electron microscopy. Zavod Lab 29:973 (in Russian)

Myasnikova LP, BoikoYuM, Ivankova EM, Marikhin VA, Radovanova EI, Solovieva OYu, Yakushev PN (2015) The influence of a solvent on the properties of gel-crystallized oriented UHMWPE threads. In: Proceedings of the IV International Conference on “Deformation and fracture of materials and nanomaterials”, Moscow, November 10–13, ISSN 2413-2209, pp 606–607

DSM info Issued: 20-09-2013 Page: 1/1 Ref.: dtm ya001

Dr. Moore R, Physical Testing Labs, Honeywell, Private Communication

Schwartz P, Netravali A, Sembach S (1986) Effects of strain rate and gauge length on the failure of ultra-high strength polyethylene fibers. Text Res J 8:502–508

Ioffe AF (1929) The physics of crystals. Gosizdat, Moscow-Leningrad (in Russian)

Marichin VA (1979) Die Struktur der ungeordnete Bereiche in den Mikrofibrillen hochorientierte Polymere. Acta Polym 30:507–514

Mjasnikova LP (1986) Hoechstorientierte Polymere-Mechanishe Eigenschaften und Strukturelle Besonderheiten. Plaste Kautsch 33:121–127

Marikhin VA, Myasnikova LP (1991) Heterogeneity of structure and mechanical properties of polymers. Makromol Chem Macromol Symp 41:209–227

Krisyuk BE, Marikhin VA, Myasnikova LP, Zaalishvili NL (1993) Structure of drawn gel-crystallized UHMWPE as revealed by spin-probe technique. Int J Polym Mater 22:161–166

Bershtein VA, Egorov VM, Marikhin VA, Myasnikova LP (1993) Relationship between melting thermodynamics and strength for ultradrawn polymers. Int J Polym Mater 22:167–176

Strawhecker KE, Cole DP (2014) Morphological and local mechanical surface characterization of ballistic fibres via AFM. J Appl Polym Sci 131:40880

Stockdale TA, Strawhecker KE, Sandoz-Rosado Wetzel ED (2016) A rapid-FIB notch technique for characterizing the internal morphology of high performance fibres. Mater Lett 176:173–176

McDaniel PB, Deitzel JM, Gillespie JW Jr (2015) Structural hierarchy and surface morphology of highly drawn ultra high molecular polyethylene fibres studied by atomic force microscopy and wide angle X-ray diffraction. Polymer 69:148–158

Milagin MF, Shishkin NI (1982) Damage in rod-shaped solids caused by stress-relief waves. Sov Phys Tech Phys 27:850–853

Egorov VM, Boiko YM, Marikhin VA, Myasnikova LP (2016) Study of ultra-strength polymer fibres via calorimetry. Phys Solid States 58:1622–1626

Schaper A, Zenke D, Schulz E, Hirte R, Taege M (1989) Structure-property relationships of high-performance polyethylene fibres. Phys Status Solidi A Appl Res 116:179–195

Smook J, Hamersma W, Pennings AJ (1984) The fracture process of ultra-high strength polyethylene fibres. J Mater Sci 19:1359–1373. doi:10.1007/BF01120049

Schaper A (1986) Defect structures in high-pressure crystallized polyethylene. Acta Polym 37:471–474

Smook J, Flinterman M, Pennings AJ (1980) Influence of spinning/hot drawing conditions on the tensile strength of porous high molecular weight polyethylene. Polym Bull 2:775–783

Smook J, Torfs JCM, van Hutten PE, Pennings AJ (1980) Ultra-high strength polyethylene by hot drawing of surface growth fibres. Polym Bull 2:293–300

Marikhin VA, Mjasnikova LP, Zenke D, Hirte R, Weigel P (1984) Ultra-high strength and ultra-high modulus fibres from polyethylene. Polym Bull 12:287–292

Bershtein VA, Savitsky AV, Egorov VM, Gorshkova IA, Demicheva VP (1984) Melting at equilibrium temperature in a zero melting range as well as inter- and intramolecular stages on the process. Polym Bull 12:165–172

Acknowledgements

This work was supported in part by the Federal Agency of Scientific Organizations of the Russian Federation.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Boiko, Y.M., Marikhin, V.A., Myasnikova, L.P. et al. Weibull statistics of tensile strength distribution of gel-cast ultra-oriented film threads of ultra-high-molecular-weight polyethylene. J Mater Sci 52, 1727–1735 (2017). https://doi.org/10.1007/s10853-016-0464-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0464-9