Abstract

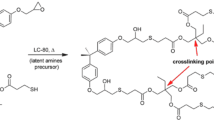

Our research group has recently found excellent shape-memory response in “thiol-epoxy” thermosets obtained with click-chemistry. In this study, we use their well-designed, homogeneous and tailorable network structures to investigate parameters for better control of the shape-recovery process. We present a new methodology to analyse the shape-recovery process, enabling easy and efficient comparison of shape-memory experiments on the programming conditions. Shape-memory experiments at different programming conditions have been carried out to that end. Additionally, the programming process has been extensively analysed in uniaxial tensile experiments at different shape-memory testing temperatures. The results showed that the shape-memory response for a specific operational design can be optimized by choosing the correct programming conditions and accurately designing the network structure. When programming at a high temperature (T ≫ T g), under high network mobility conditions, high shape-recovery ratios and homogeneous shape-recovery processes are obtained for the network structure and the programmed strain level (ε D ). However, considerably lower stress and strain levels can be achieved. Meanwhile, when programming at temperatures lower than T g, considerably higher stress and strain levels are attained but under low network mobility conditions. The shape-recovery process heavily depends on both the network structure and ε D. Network relaxation occurs during the loading stage, resulting in a noticeable decrease in the shape-recovery rate as ε D increases. Moreover, at a certain level of strain, permanent and non-recoverable deformations may occur, impeding the completion and modifying the whole path of the shape-recovery process.

Similar content being viewed by others

References

Lewis CL, Meng Y, Anthamatten M (2015) Well-defined shape-memory networks with high elastic energy capacity. Macromolecules 48(14):4918–4926

Wang A, Li G (2015) Stress memory of a thermoset shape memory polymer. J Appl Polym Sci 132(24):42112

Arrieta JS, Diani J, Gilormini P (2014) Cyclic and monotonic testing of free and constrained recovery properties of a chemically crosslinked acrylate. J Appl Polym Sci 131(2):39813

Arrieta JS, Diani J, Gilormini P (2014) Experimental characterization and thermoviscoelastic modeling of strain and stress recoveries of an amorphous polymer network. Mech Mater 68:95–103

Anthamatten M, Roddecha S, Li J (2013) Energy storage capacity of shape-memory polymers. Macromolecules 46:42304234

Yakacki CM, Shandas R, Safranski D, Ortega AM, Sassaman K, Gall K (2008) Strong, tailored, biocompatible shape-memory polymer networks. Adv Funct Mater 18:2428–2435

Lakhera N, Yakacki CM, Nguyen TD, Frick CP (2012) Partially constrained recovery of (meth)acrylate shape-memory polymer networks. J Appl Polym Sci 126:72–82

Hager MD, Bode S, Weber C, Schubert US (2015) Shape memory polymers: past, present and future developments. Prog Polym Sci 49–50:3–33

Scalet G, Auricchio F, Bonetti E, Castellani L, Ferri D, Pachera M, Scavello F (2015) An experimental, theoretical and numerical investigation of shape memory polymers. Int J Plast 67:127–147

Lendlein A, Sauter T (2013) Shape-memory effect in polymers. Macromol Chem Phys 214:1175–1177

Anis A, Faiz S, Luqman M, Poulose AM, Gulrez SKH, Shaikh H, Al-Zahrani SM (2013) Developments in shape memory polymeric materials. Polym Plast Technol Eng 52:1574–1589

Habault D, Zhang H, Zhao Y (2013) Light-triggered self-healing and shape-memory polymers. Chem Soc Rev 42:7244–7256

Santhosh Kumar KS, Biju R, Reghunadhan Nair CP (2013) Progress in shape memory epoxy resins. React Funct Polym 73:421–430

Belmonte A, Guzmán D, Fernández-Francos X, De la Flor S (2015) Effect of the network structure and programming temperature on the shape-memory response of thiol-epoxy “click” systems. Polymers 7(10):2146–2164

Belmonte Alberto et al (2016) Network structure dependence on unconstrained isothermal-recovery processes for shape-memory thiol-epoxy “click” systems. Mech Time Depend Mater. doi:10.1007/s11043-016-9322-z

Feldkamp DM, Rousseau IA (2011) Effect of chemical composition on the deformability of shape-memory epoxies. Macromol Mater Eng 296:1128–1141

Binder WH, Sachsenhofer R (2007) “Click” chemistry in polymer and materials science. Macromol Rapid Commun 28:15–54

Carlborg CF, Vastesson A, Liu Y, Van Der Wijngaart W, Johansson M, Haraldsson T (2014) Functional off-stoichiometry thiol-ene-epoxy thermosets featuring temporally controlled curing stages via an UV/UV dual cure process. J Polym Sci 52(2):604–2615

Flores M, Tomuta AM, Fernández-Francos X, Ramis X, Sangermano M, Serra À (2013) A new two-stage curing system: thiol-ene/epoxy homopolymerization using an allyl terminated hyperbranched polyester as reactive modifier. Polymer 54:5473–5481

Guzmán D, Ramis X, Fernández-Francos X, Serra À (2014) New catalysts for diglycidyl ether of bisphenol a curing based on thiol-epoxy click reaction. Eur Polym J. 59:377–396

Brändle A, Khan A (2012) Thiol-epoxy “click” polymerization: efficient construction of reactive and functional polymers. Polym Chem. 3:3224–3227

Berg GJ, McBride MK, Wang C, Bowman CN (2014) New directions in the chemistry of shape memory polymers. Polymer 55:1–24

Xiao R, Guo J, Nguyen TD (2015) Modeling the multiple shape memory effect and temperature memory effect in amorphous polymers. RSC Adv 5:416–423

Barot G, Rao IJ (2006) Constitutive modeling of the mechanics associated with crystallizable shape memory polymers. Zeitschrift Fur Angew Math Und Phys. 57:652–681

Diani J, Gilormini P, Frédy C, Rousseau IA (2012) Predicting thermal shape memory of crosslinked polymer networks from linear viscoelasticity. Int J Solids Struct 49:793–799

Graessley WW (1975) Statistical Mechanics of Random Coil Networks. Rubber Chem Technol 48:1008–1017

Miller DR, Macosko CW (1976) A new derivation of postgel properties of network polymers. Rubber Chem Technol 49:1219–1231

Charlesworth JM (1988) Effect of crosslink density on molecular relaxations in diepoxide-diamine network polymers. The rubbery plateau region 28:230–236

Lesser A, Crawford E (1997) The role of network architecture on the glass transition temperature of epoxy resins. J Appl Polym Sci 66:387–395

Pascault JP, Sautereau H, Verdu J, Williams RJJ (2002) Thermosetting polymers, 1st edn. CRC Press, New York

Li G, Xu W (2011) Thermomechanical behavior of thermoset shape memory polymer programmed by cold-compression: testing and constitutive modeling. J Mech Phys Solids 59:1231–1250. doi:10.1016/j.jmps.2011.03.001

Li G, Wang A (2016) Cold, warm, and hot programming of shape memory polymers. J Polym Sci 54:1319–1339. doi:10.1002/polb.24041

Pandini S, Bignotti F, Baldi F, Passera S (2013) Network architecture and shape memory behavior of cold-worked epoxies. J Intell Mater Syst Struct 24:1583–1597. doi:10.1177/1045389X13478275

Feldkamp DM, Rousseau IA (2010) Effect of the deformation temperature on the shape-memory behavior of epoxy networks. Macromol Mater Eng 295:726–734

Yakacki CM, Willis S, Luders C, Gall K (2008) Deformation limits in shape-memory polymers. Adv Eng Mater 10:112–119

Leonardi AB, Fasce LA, Zucchi IA, Hoppe CE, Soulé ER, Pérez CJ, Williams JJ (2011) Shape memory epoxies based on networks with chemical and physical crosslinks. Eur Polym J. 47(3):362–369

Santiago D, Fernández-Francos X, Ferrando F, De la Flor S (2015) Shape-memory effect in hyperbranched poly (ethyleneimine)-modified epoxy thermosets. J Polym Sci 53(13):924–933

Acknowledgements

The authors would like to thank MICINN (MAT2014-53706-C03-01 and MAT2014-53706-C03-02) and Generalitat de Catalunya (2014-SGR-67) for its financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Belmonte, A., Fernández-Francos, X. & De la Flor, S. New understanding of the shape-memory response in thiol-epoxy click systems: towards controlling the recovery process. J Mater Sci 52, 1625–1638 (2017). https://doi.org/10.1007/s10853-016-0456-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0456-9