Abstract

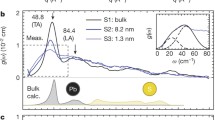

Phonon scattering in crystalline systems can be strongly dictated by a wide array of defects, many of which can be difficult to observe via standard microscopy techniques. We experimentally demonstrate that the phonon thermal conductivity of MgO thin films is proportional to the crystal’s coherence length, a property of a solid that quantifies the length scale associated with crystalline imperfections. Sputter-deposited films were prepared on (100)-oriented silicon and then annealed to vary the crystalline coherence, as characterized using x-ray diffraction line broadening. We find that the measured thermal conductivity of the MgO films varies proportionally with crystalline coherence length, which is ultimately limited by the grain size. The microstructural length scales associated with crystalline defects, such as small-angle tilt boundaries, dictate this crystalline coherence length, and our results demonstrate the role that this length scale has on the phonon thermal conductivity of thin films. Our results suggest that this crystalline coherence length scale provides a measure of the limiting phonon mean free path in crystalline solids, a quantity that is often difficult to measure and observe with more traditional imagining techniques.

Similar content being viewed by others

References

Klemens PG (1955) The scattering of low-frequency lattice waves by static imperfections. Proc Phys Soc Lond Sect A 68 1113–1128

Srivastava GP (1990) The physics of phonons. Taylor and Francis, New York

Marconet AM, Asheghi M, Goodson KE (2013) From the casimir limit to phononic crystals: twenty years of phonon transport studies using silicon-on-insulator technology. J Heat Transfer 135:061601

Abeles B (1963) Lattice thermal conductivity of disordered semiconductor alloys at high temperatures. Phys Rev 131:1906–1911

Cheaito R, Duda JC, Beechem TE, Hattar K, Ihlefeld JF, Medlin DL, Rodriguez MA, Campion MJ, Piekos ES, Hopkins PE (2012) Experimental investigation of size effects on the thermal conductivity of silicon-germanium alloy thin films. Phys Rev Lett 109:195901

Wang Z, Alaniz JE, Jang W, Garay JE, Dames C (2011) Thermal conductivity of nanocrystalline silicon: importance of grain size and frequency-dependent mean free paths. Nano Lett 11:2206–2213

Donovan BF, Foley BM, Ihlefeld JF, Maria J-P, Hopkins PE (2014) Spectral phonon scattering effects on the thermal conductivity of nano-grained barium titanate. Appl Phys Lett 105:082907

Foley BM, Brown-Shaklee HJ, Duda JC, Cheaito R, Gibbons BJ, Medlin D, Ihlefeld JF, Hopkins PE (2012) Thermal conductivity of nano-grained SrTiO3 thin films. Appl Phys Lett 101:231908

Ni Y, Xiong S, Volz S, Dumitrica T (2014) Thermal transport along the dislocation line in silicon carbide. Phys Rev Lett 113:124301

Bierman MJ, Lau YKA, Kvit AV, Schmitt AL, Jin S (2008) Dislocation-driven nanowire growth and Eshelby twist. Science 320:1060–1063

Jacobs BW, Crimp MA, McElroy K, Ayres VM (2008) Nanopipes in gallium nitride nanowires and rods. Nano Lett 8:4353–4358

Zhu J, Peng H, Marshall AF, Barnett DM, Nix WD, Cui Y (2008) Formation of chiral branched nanowires by the Eshelby twist. Nat Nanotechnol 3:477–481

Morin SA, Jin S (2010) Screw dislocation-driven epitaxial solution growth of ZnO nanowires seeded by dislocations in GaN substrates. Nano Lett 10:3459–3463

Meng F, Morin SA, Forticaux A, Jin S (2013) Screw dislocation driven growth of nanomaterials. Acc Chem Res 46:1616–1626

Kim SI, Lee KH, Mun HA, Kim HS, Hwang SW, Roh JW, Yang DJ, Shin WH, Li XS, Lee YH, Snyder GJ, Kim SW (2015) Dense dislocation arrays embedded in grain boundaries for high-performance bulk thermoelectrics. Science 348:109–114

Hopkins PE (2013) Thermal transport across solid interfaces with nanoscale imperfections: effects of roughness, disorder, dislocations, and bonding on thermal boundary conductance. ISRN Mech Eng 2013:682586

Hopkins PE, Duda JC, Clark SP, Hains CP, Rotter TJ, Phinney LM, Balakrishnan G (2011) Effect of dislocation density on thermal boundary conductance across GaSb/GaAs interfaces. Appl Phys Lett 98:161913

Su Z, Huang L, Liu F, Freedman JP, Porter LM, Davis RF, Malen JA (2012) Layer-by-layer thermal conductivities of the Group III nitride films in blue/green light emitting diodes. Appl Phys Lett 100:201106

Ihlefeld JF, Foley BM, Scrymgeour DA, Michael JR, McKenzie BB, Medlin DL, Wallace M, Trolier-McKinstry S, Hopkins PE (2015) Room temperature voltage tunable thermal conductivity via reconfigurable interfaces in ferroelectric thin films. Nano Lett 15:1791–1795

Hopkins PE, Adamo C, Ye L, Huey BD, Lee SR, Schlom DG, Ihlefeld JF (2013) Effects of coherent ferroelastic domain walls on the thermal conductivity and kapitza conductance in bismuth ferrite. Appl Phys Lett 102:121903

Mante AJH, Volger J (1966) The thermal conductivity of BaTiO3 in the neighbourhood of its ferroelectric transition temperatures. Phys Lett 24A:139–140

Ihlefeld JF, Ginn JC, Shelton DJ, Matias V, Rodriguez MA, Kotula PG, Carroll JF, Boreman GD, Clem PG, Sinclair MB (2010) Crystal coherence length effects on the infrared optical response of MgO thin films. Appl Phys Lett 97:191913

Cahill DG (2004) Analysis of heat flow in layered structures for time-domain thermoreflectance. Rev Sci Instrum 75:5119–5122

Hubbard KJ, Schlom DG (1996) Thermodynamic stability of binary oxides in contact with silicon. J Mater Res 11:2757–2776

Scherrer P (1918) Bestimmung der Größe und der inneren Struktur von Kolloidteilchen mittels Röntgenstrahlen. Nachrichten von der Gesellschaft der Wissenschaften zu Göttingen, Mathematisch-Physikalische Klasse 1918:98–100

ASTM (2014) Standard test methods for determining average grain size, ASTM International designation: E112–13. ASTM, West Conshohocken, pp 1–28

Thomsen C, Strait J, Vardeny Z, Maris HJ, Tauc J, Hauser JJ (1984) Coherent phonon generation and detection by picosecond light pulses. Phys Rev Lett 53:989–992

Thomsen C, Grahn HT, Maris HJ, Tauc J (1986) Surface generation and detection of phonons by picosecond light pulses. Phys Rev B 34:4129–4138

Madelung O, Rossler U, Schulz M (1999) Magnesium oxide (MgO) crystal structure, lattice parameters, thermal expansion. In: Landolt-Börnstein—Group III Condensed matter. Springer, Berlin

Luxon JT, Montgomery DJ, Summitt R (1969) Effect of particle size and shape on the infrared absorption of magnesium oxides powders. Phys Rev 188:1345–1356

Schmidt Aaron J, Chen Xiaoyuan, Chen Gang (2008) Pulse accumulation, radial heat conduction, and anisotropic thermal conductivity in pump-probe transient thermoreflectanc. Rev Sci Instrum 79(11):114902

Cahill DG (2004) Analysis of heat flow in layered structures for time-domain thermoreflectance. Rev Sci Instrum 75(12):5119–5122

Cahill DG, Goodson K, Majumdar A (2002) J Heat Transf 124(2):223–241

Hopkins Patrick E, Serrano Justin R, Phinney Leslie M, Kearney Sean P, Grasser Thomas W, Thomas Harris C (2010) Criteria for cross-plane dominated thermal transport in multilayer thin film systems during modulated laser heating. J Heat Transf 132(8):081302

Touloukian YS, Buyco EH (1970) Thermophysical properties of matter—specific heat: metallic elements and alloys. IFI/Plenum, New York

Parks GS, Kelley KK (1926) The heat capacities of some metallic oxides. J Phys Chem 30:47–55

Touloukian Y, Powell R, Ho C, Klemens P (1970) Thermophysical properties of matter—specific heat: nonmetallic solids. IFI/Plenum, New York

Giri A, Niemelä J-P, Tynell T, Gaskins JT, Donovan BF, Karppinen M, Hopkins PE (2016) Heat-transport mechanisms in molecular building blocks of inorganic/organic hybrid superlattices. Phys Rev B 93:115310

Touloukian YS, Powell RW, Ho CY, Klemens PG (1970) Thermophysical properties of matter—Thermal conductivity: nonmetallic solids. IFI/Plenum, New York

Cahill DG, Watson SK, Pohl RO (1992) Lower limit to the thermal conductivity of disordered crystals. Phys Rev B 46:6131–6140

Sangster MJL, Peckham G, Saunderson DH (1970) Lattice dynamics of magnesium oxide. J Phys C 3:1026–1036

Morelli DT, Slack GA (2006) High lattice thermal conductivity solids. In: Shinde SL, Goela JS (eds) High thermal conductivity materials. Springer, NewYork, pp 37–68

Gorham CS, Hattar K, Cheaito R, Duda JC, Gaskins JT, Beechem TE, Ihlefeld JF, Biedermann LB, Piekos ES, Medlin DL, Hopkins PE (2014) Ion irradiation of the native oxide/silicon surface increases the thermal boundary conductance across aluminum/silicon interfaces. Phys Rev B 90:024301

Acknowledgements

The authors would like to thank J. T. Gaskins for electron beam evaporation of the aluminum transducers. The authors acknowledge the use of the Analytical Instrument Facility (AIF) at North Carolina State University, which is supported by NSF contracts DMR 1337694 and DMR 1108071. This work was supported by the Laboratory Directed Research and Development (LDRD) program at Sandia National Laboratories, the Office of Naval Research (N00014-15-12769), and the National Science Foundation (EECS-1509362). Sandia National Laboratories is a multiprogram laboratory managed and operated by Sandia Corporation, a wholly owned subsidiary of Lockheed Martin Company, for the United States Department of Energy’s National Nuclear Security Administration under contract DE-AC04–94AL85000.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meyer, K.E., Cheaito, R., Paisley, E. et al. Crystalline coherence length effects on the thermal conductivity of MgO thin films. J Mater Sci 51, 10408–10417 (2016). https://doi.org/10.1007/s10853-016-0261-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-016-0261-5